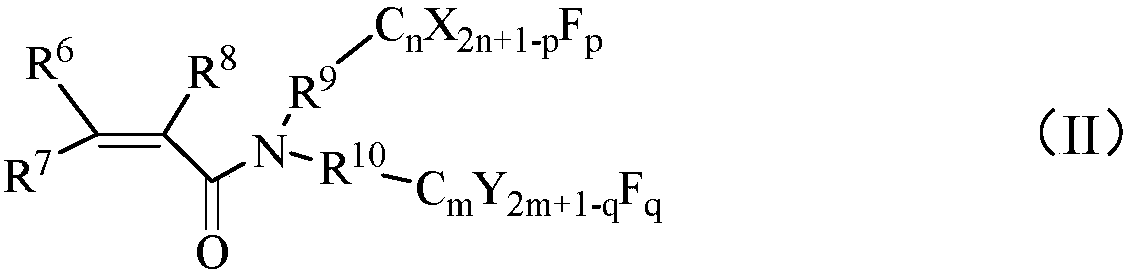

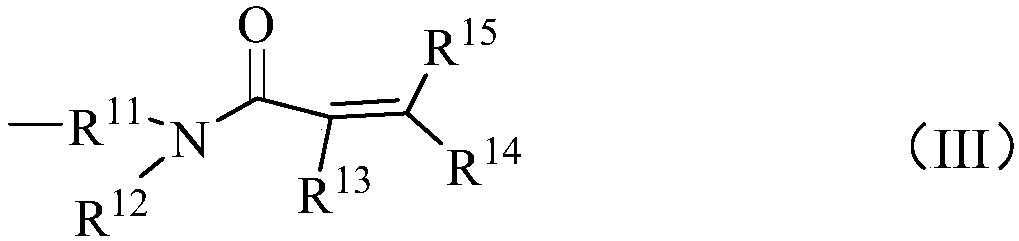

Acrylamide nano coating and preparation method thereof

A technology of acrylamide and nano-coating, which is applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of rising cost and wasting monomer, and achieve uniform thickness, reduce cost, and excellent durability The effect of acidity and alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A kind of acrylamide nano-coating and preparation method thereof go through the following steps:

[0053] (1) A metal aluminum block of 5cm×5cm is placed in a 100L plasma vacuum reaction chamber, and the reaction chamber is continuously evacuated to make the vacuum degree reach 0.1 mTorr.

[0054] (2) Introduce helium gas with a flow rate of 100 sccm, turn on the radio frequency plasma discharge to pretreat the metal aluminum block (that is, turn on the radio frequency pretreatment plasma discharge), the discharge power in the pretreatment stage is 80W, and the discharge is continuous 100s.

[0055] (3) After the introduction of the monomer 1a, the monomer 2a is introduced, and the nano-coating is prepared by chemical vapor deposition on the surface of the substrate. During the coating preparation process, the flow rate of the two monomers was 150 μL / min, and the feeding time was 600 s and 400 s, respectively. The plasma discharge for pretreatment was adjusted to the ...

Embodiment 2

[0061] A kind of acrylamide nano-coating and preparation method thereof go through the following steps:

[0062] (1) Place the PCB of the electronic watch in a 1000L plasma vacuum reaction chamber, and continuously evacuate the reaction chamber to make the vacuum degree reach 10 millitorr.

[0063] (2) Introduce argon gas with a flow rate of 200sccm, turn on the radio frequency plasma discharge to pretreat the PCB of the electronic watch (that is, turn on the radio frequency pretreatment plasma discharge), the pretreatment plasma discharge power is 500W, and last Discharge for 100s.

[0064] (3) The monomer 1b is passed in, and then the monomer 2b is passed in after completion, and the nano-coating is prepared by chemical vapor deposition on the surface of the substrate.

[0065] During the coating preparation process, the flow rate of the two monomers was 150 μL / min, and the feeding time was 1000 s and 1600 s, respectively. The plasma discharge for pretreatment was adjusted...

Embodiment 3

[0071] A kind of acrylamide nano-coating and preparation method thereof go through the following steps:

[0072] (1) The magnesium alloy is placed in a 4000L plasma vacuum reaction chamber, and the reaction chamber is continuously evacuated so that the vacuum degree reaches 100 mTorr.

[0073] (2) Introduce argon gas with a flow rate of 200 sccm, turn on the radio frequency plasma discharge to pretreat the magnesium alloy substrate (that is, turn on the radio frequency pretreatment plasma discharge), the discharge power in the pretreatment stage is 150W, and the discharge is continued for 100s .

[0074] (3) Simultaneously feed monomer 1c and monomer 2c, and perform chemical vapor deposition on the surface of the substrate to prepare a nano-coating. During the coating preparation process, the flow rate of the two monomers was 170 μL / min, and the feeding time was 1800 s, respectively. The plasma discharge for pretreatment was adjusted to the plasma discharge for deposition. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com