System and method of flocculation combined with vacuum preloading for treatment of blown fill foundation

A soil filling and vacuum technology, applied in chemical instruments and methods, soil protection, fertilizer mixtures, etc., can solve the problems of conflicting strategic goals of sustainable development, waste of land, inability to cultivate, etc., to meet the needs of engineering construction, Solve the effect of poor permeability and enhance mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

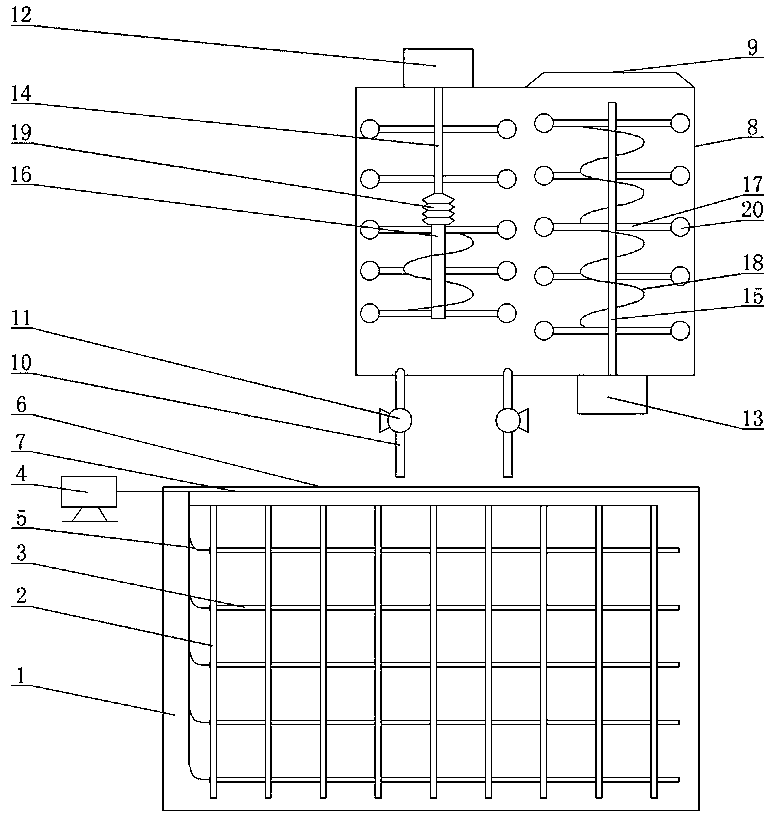

[0020] refer to figure 1 As shown, the system of flocculation combined with vacuum preloading treatment of dredged fill soil foundation provided by the present invention includes a treatment area 1, a vertical drainage board 2, a horizontal drainage board 3 and a vacuum pump 4, and the vertical drainage board 2 and the horizontal drainage board 3 respectively pass through Drainage pipe 5 is connected with vacuum pump 4, and treatment area 1 is laid with geomembrane 6 and geotextile 7, and treatment area 1 side is provided with stirring device, and stirring device comprises tank body 8, and tank body 8 upper end is provided with entrance 9, and lower end is provided with. There is a conveying pipe 10 aligned with the treatment area 1, a conveying pump 11 is arranged on the conveying pipe 10, a first motor 12 is provided at the upper end of one side of the tank body 8, a second motor 13 is provided at the lower end of the other side, and a There is a first rotating shaft 14 conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com