Metallic molten pool internal contour online measurement device and method

A technology of metal molten pool and measuring equipment, which is applied in the direction of measuring devices, instruments, optical devices, etc., to achieve the effect of realizing the quality of parts manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

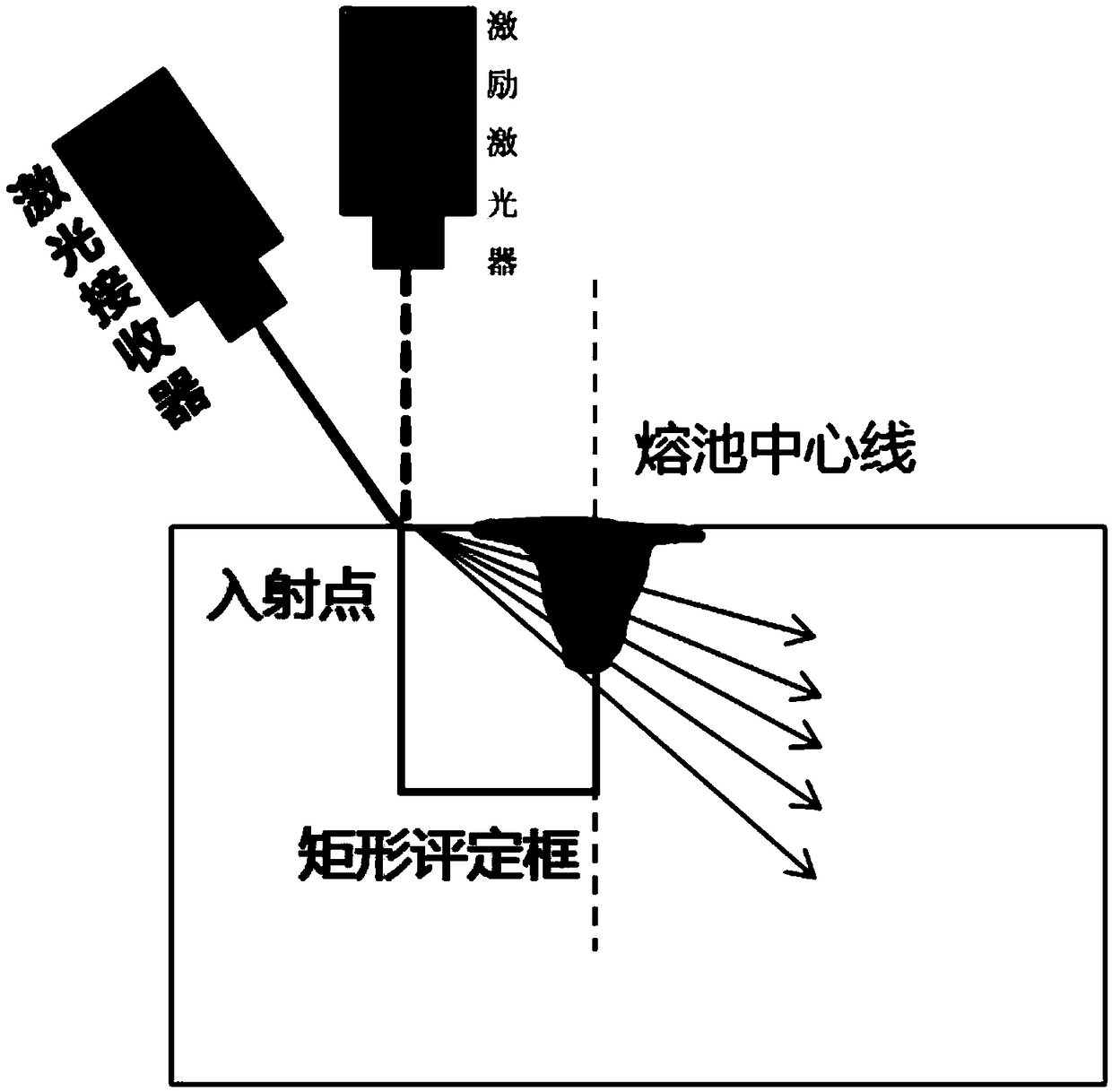

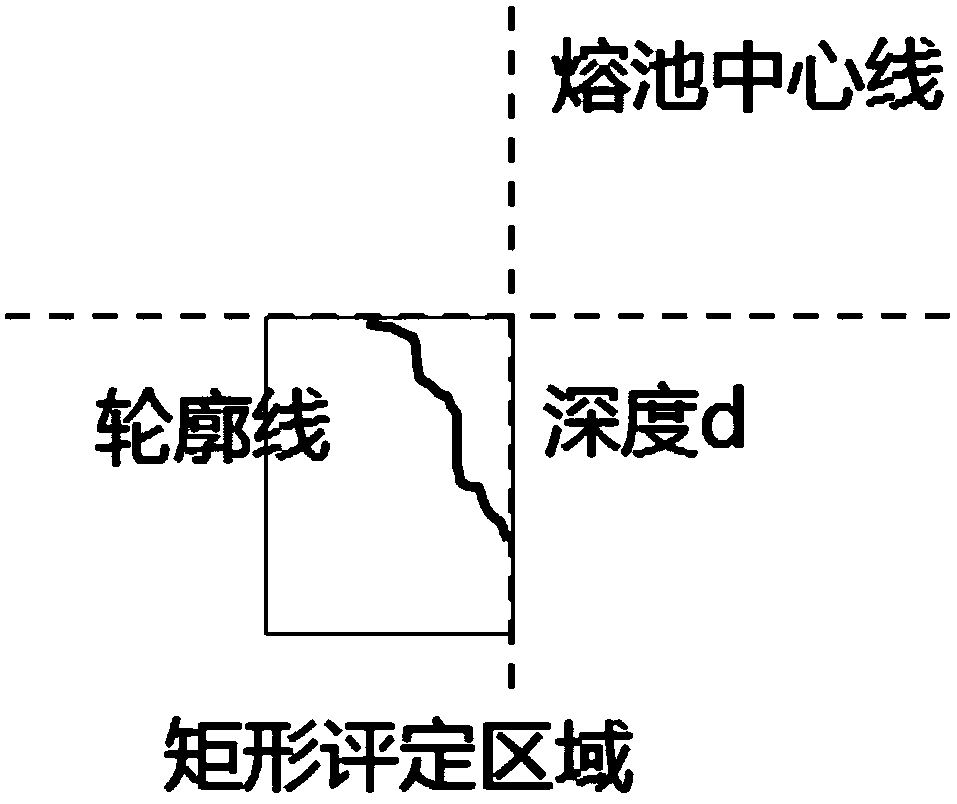

[0028] On-line measurement equipment for the internal profile of the molten metal pool, which includes an excitation component, a receiving component, and a computer for data analysis and control. The excitation component includes an excitation laser, and a beam splitter for dividing the beam emitted by the excitation laser into multiple beams. The array optical fiber is used to respectively accept multiple beams, and the computer has a dynamic modulation module for dynamically modulating the beams. The receiving component includes a laser receiver, a receiving optical fiber group, and a motion mechanism that drives the receiving optical fiber group to move, or it includes a laser receiver and a vibrating mirror system.

[0029] Such as figure 1 Shown, the on-line measurement method of the internal profile of molten metal pool, it comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com