A composite excited amorphous alloy axial reluctance motor

A technology of amorphous alloy and composite excitation, which is applied in the manufacture of motor generators, magnetic circuits, electric components, etc., can solve the difficulty of increasing the process and assembly of the assembled stator core, increase the copper loss of the excitation winding, and reduce the magnetic adjustment of the motor capacity and other issues, to achieve good speed regulation and constant voltage power generation capacity, improve reliability, and reduce the effect of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

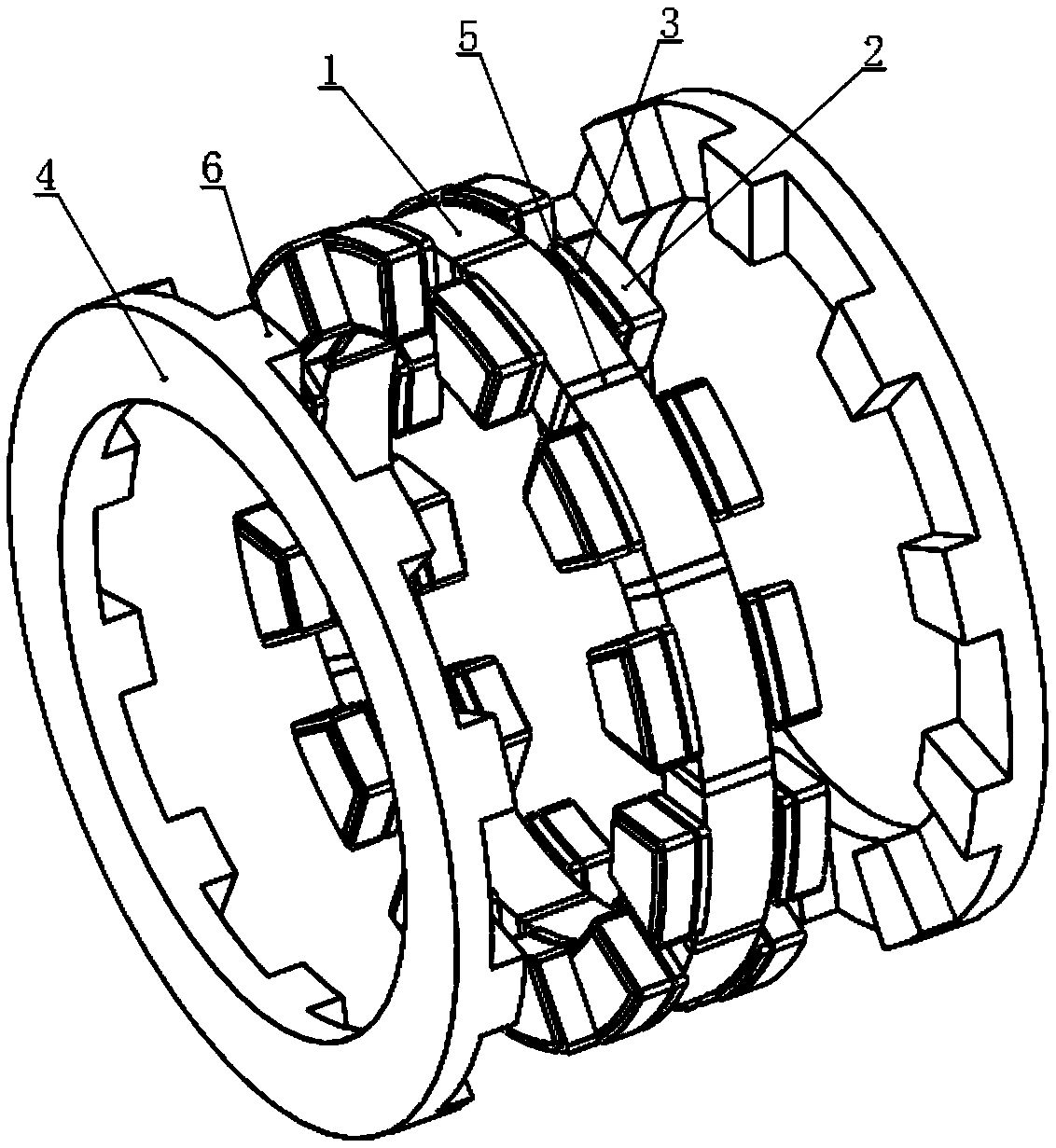

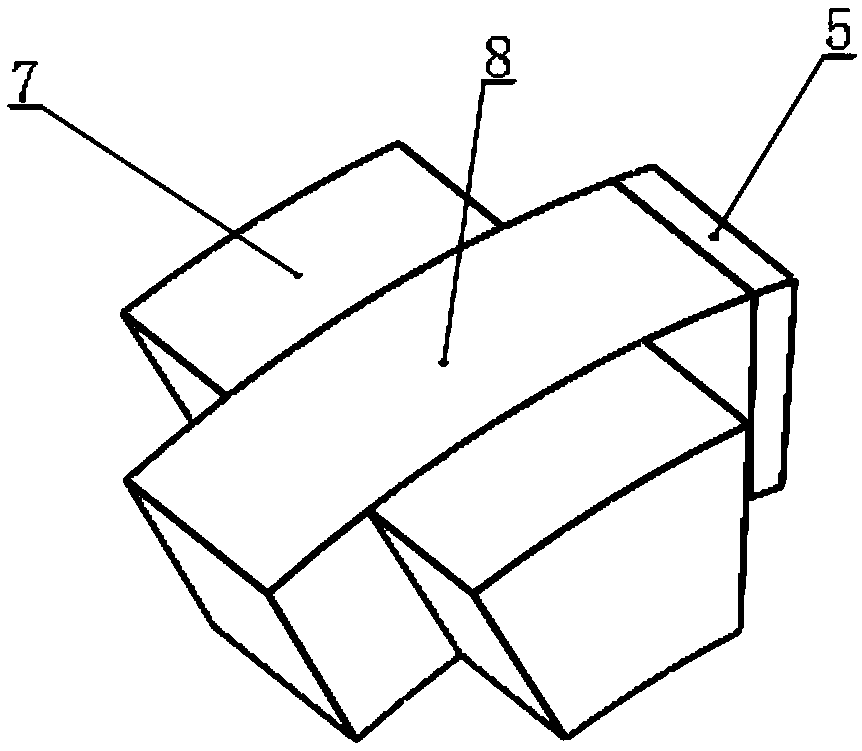

[0036]A composite excitation amorphous alloy axial reluctance motor, including a stator, a rotor, a permanent magnet 5, a rotating shaft 11 and a casing 9, the stator includes a stator core 1 and windings, the rotor includes a rotor yoke 4 and ferromagnetic poles 6; the stator core 1 is a ring-shaped modular amorphous alloy stator core composed of 6*n modules, n is a positive integer, and each module is composed of a stator yoke 8, a stator tooth 7 and one side of the stator yoke 8 in the circumferential direction Composed of permanent magnets 5, the polarities of adjacent permanent magnets 5 are opposite; the stator core 1 side has 6*n stator teeth, 6*n open slots, and the number of permanent magnets 5 poles is 6*n. The rotor is located on the tooth side of the stator, and the rotor yoke 4 of the rotor has 5*n ferromagnetic poles 6 near the stator side, and the ferromagnetic poles (6) have magnetic permeability. The windings are wound on the stator teeth 7; the windings inclu...

Embodiment 2

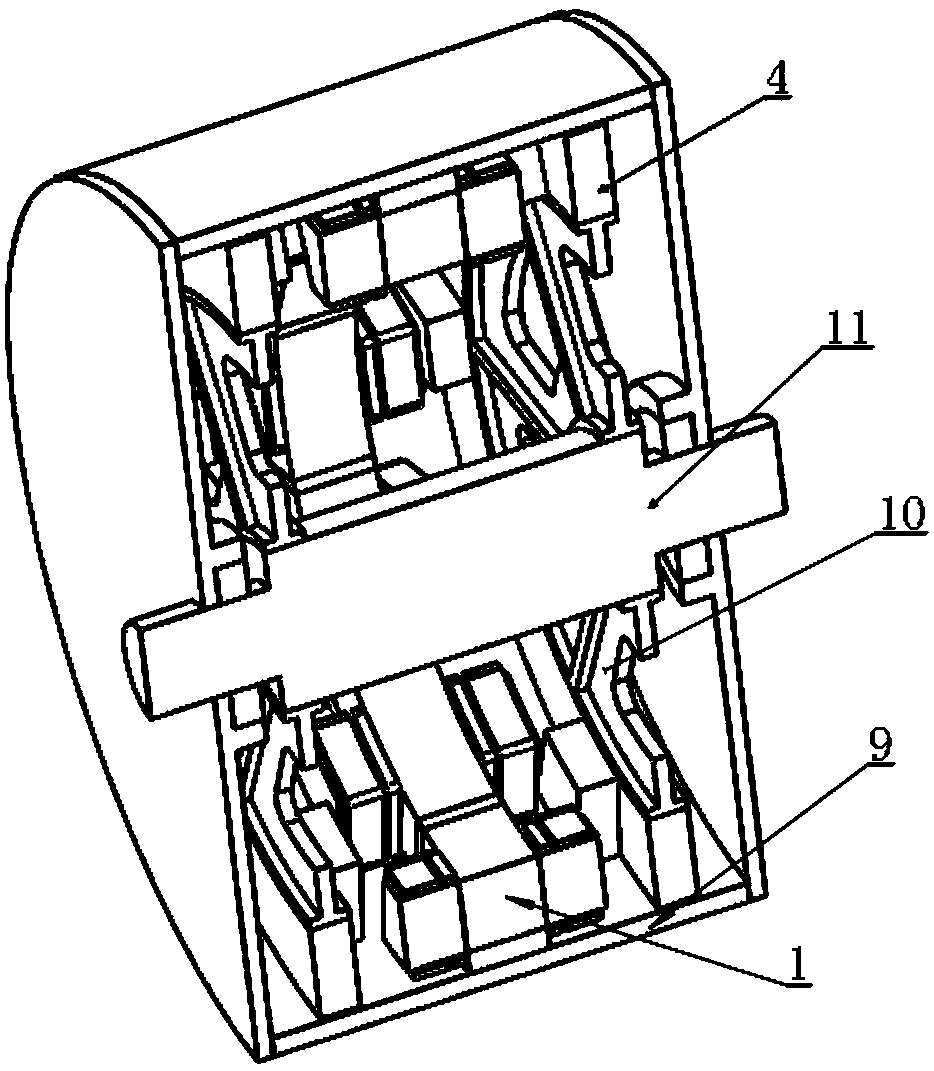

[0038] Such as figure 1 , figure 2 and image 3 As shown, a composite excitation amorphous alloy axial reluctance motor includes a stator, a rotor, a permanent magnet 5, a rotating shaft 11 and a casing 9, the stator includes a stator core 1 and windings, and the rotor includes a rotor yoke 4 and ferromagnetic poles 6 ; Stator core 1 is a ring-shaped modular amorphous alloy stator core composed of 6*n modules, n is a positive integer, and each module is composed of stator yoke 8, stator tooth 7 and stator yoke 8 circumference The polarity of the adjacent permanent magnets 5 is opposite; there are 6*n stator teeth on both sides of the stator core 1, and 6*n open slots on both sides, and the permanent magnets have 5 poles The number is 6*n, the two rotors are respectively located on both sides of the stator, and the rotor yoke 4 of each rotor has 5*n ferromagnetic poles 6 on the side close to the stator. The stator core 1 is a modular amorphous alloy, and each module is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com