A ceramic sanitary ceramic body and preparation method thereof

A technology for sanitary ceramics and blanks, applied in the field of ceramic sanitary ceramics blanks and their preparation, can solve the problems of limited use, environmental problems, insufficient strength, etc. The effect of flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

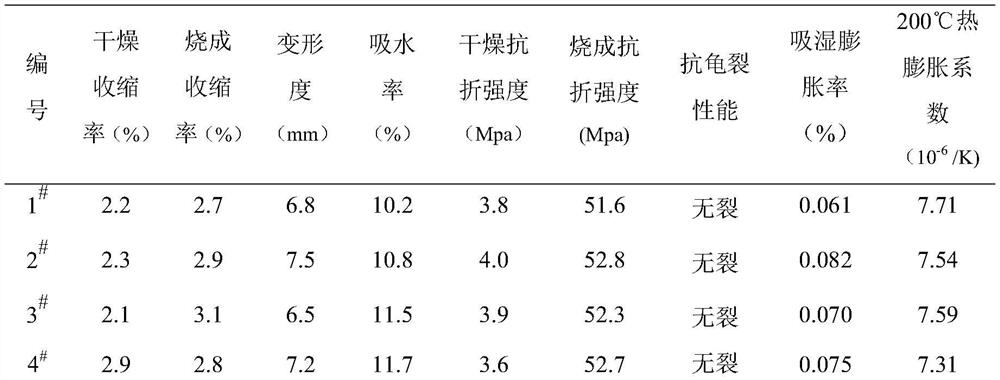

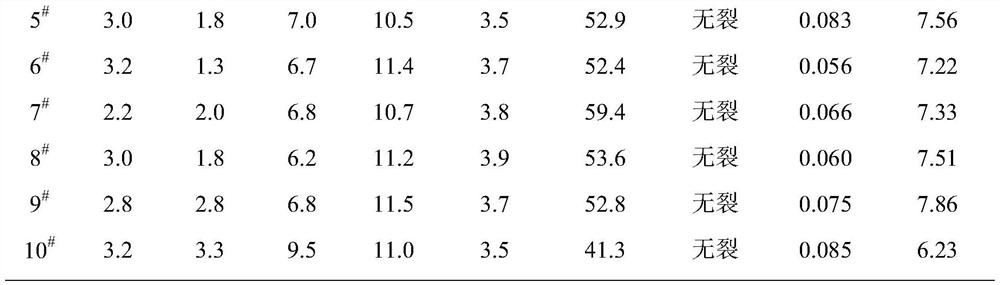

Examples

preparation example Construction

[0040] Another aspect of the present invention provides a method of preparing the cessic bathing ceramic blank, comprising the steps of:

[0041] (1) Making mud: According to the above formulation amount, the material is weighed, adding the amount of boron nitride fine powder of the formulation, and the water glass is added as a condensing agent, and then mixed with water, stir evenly with spherical mill, after sieve, after the iron Preparation of mud;

[0042] (2) Press the slurry: inject the mud into the plaster mold;

[0043] (3) Drying: Dry after dumping removal of the sedge to obtain a grading;

[0044] (4) Burning: Burning the grading in the kiln.

[0045] In a specific embodiment, the performance requirements of the mud: the mud concentration of 346 ~ 370 g / 200ml, 350 mesh screen is 6% to 10%, particle size (0 50 ~ 60S, V 30 110 ~ 130s, the jam speed is 5 ~ 7mm / 45min.

[0046] In a specific embodiment, the drying method is: first drying at 25 to 50 ° C for 12 h, and the...

Embodiment 1

[0050] The ceramic billet provided in this example includes a blank and auxiliary, the blank includes each component of the following weight: 20% of the southern black mud, 8% of the southern kaolin, 11% of scrap powder, 8% of the blast furnace slag, 15% in the southern leaves 3% talc, 10% of calcined kaolin, 5% of Dolomite, 15% of Quartz, 5%; the adjuvant is boron nitride fine powder, which is 0.5% of the mass of the blank.

[0051] The chemical composition of the cememium is SiO 2 59.4%, Al 2 O 3 20.2%, Fe 2 O 3 1.2%, TIO 2 0.26%, CaO 6.8%, MgO 3.2%, K 2 O 1.1%, NA 2 O 0.2% and the burns were 7.27%.

[0052] The preparation method of the ceramic billet is as follows:

[0053] (1) Make a mud: According to the above formulation amount, the formulation amount of boron nitride fine powder is added, and the water glass is added as a condensing agent, and the water is added, and the ball mill grinding is applied after stirring. 3 hours. After sieve, prepared a grout-molded mud after i...

Embodiment 2

[0057] The ceramic billet provided in this embodiment includes a blank and auxiliary, the blank includes each component of the following weight: 10% of the black mud, 5% in the south, 8% of scrap powder, 10% of the blast furnace slag, 20% in the southern leaf stone 5% talc, 15% of calcined kaolin, 1% of Dolomite, 20% of Quartz, 6% of the silicahydrate; the adjuvant is boron nitride fine powder, which is 0.2% of the mass of the blank.

[0058] The chemical composition of the cememium is SiO 2 63.9%, Al 2 O 3 19.4%, Fe 2 O 3 0.97%, TIO 2 0.21%, CaO 6.74%, MGO 3.20%, K 2 0.92%, NA 2 O 0.19% and the burns were 4.13%.

[0059] The preparation method of the ceramic billet is as follows:

[0060] (1) Production of mud: According to the above formulation amount, the formulation amount of boron nitride fine powder is added, and the water glass is added as a condensing agent, and then water is added, and the ball mill grinding is loaded after stirring. After sieve, prepared a grout-molded m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com