Imidazole ionic liquid modified bacterial cellulose antibacterial film and preparation method thereof

A technology of imidazole ionic liquid and bacterial cellulose membrane, which is applied in the field of imidazole ionic liquid modified bacterial cellulose antibacterial membrane and its preparation, can solve the problems of bacterial cellulose not having antibacterial properties, limited application scope and the like, so as to inhibit skin infection , Conducive to wound recovery, the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of imidazolium ionic liquid modified bacterial cellulose antibacterial membrane comprises the steps:

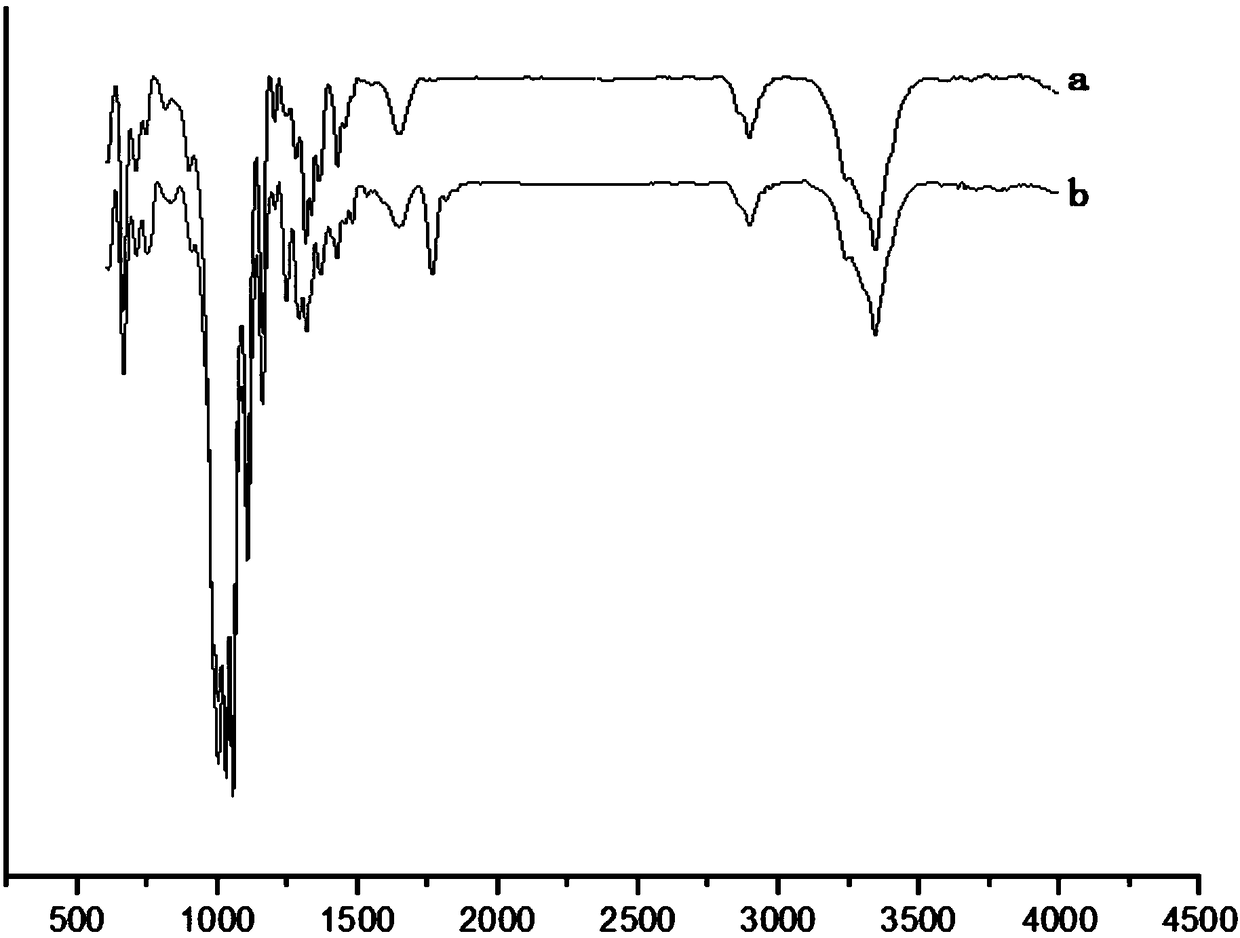

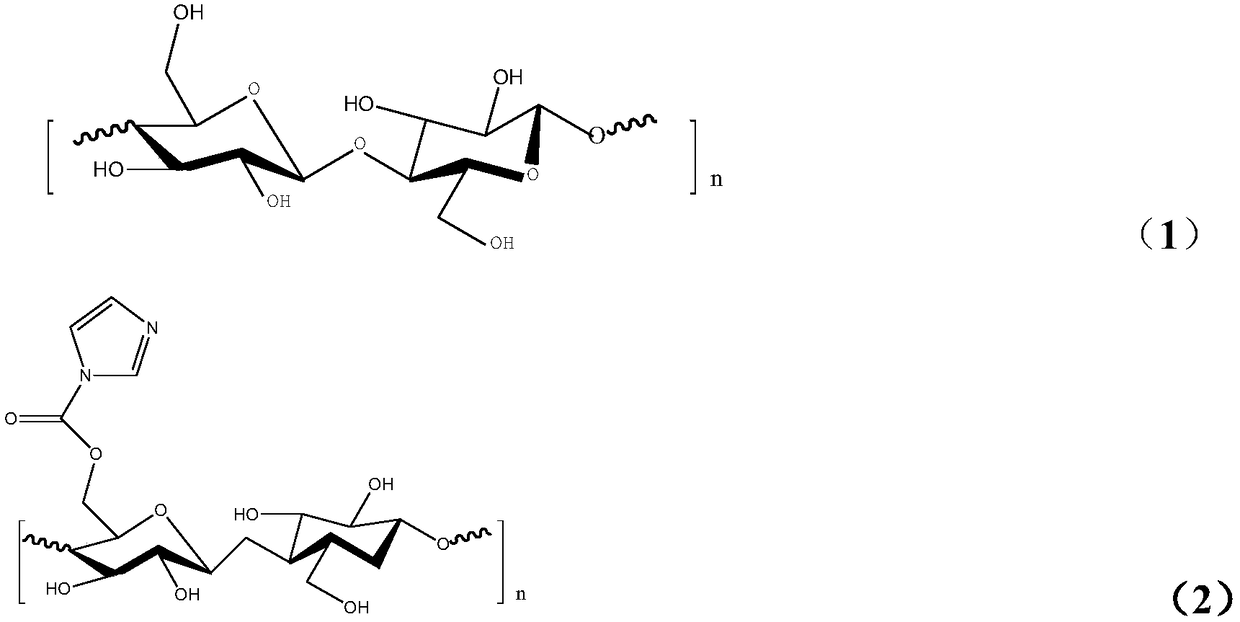

[0025] Step 1: Dissolve carbonyldiimidazole in DMSO to obtain a mixed liquid, place the bacterial cellulose membrane in the mixed liquid, immerse the bacterial cellulose membrane in the mixed liquid, stir the mixture at 40-45°C for 24-36 hours, and remove the supernatant The liquid was filtered off to obtain product 1. Product 1 was washed three times with DMSO. The structural formula of bacterial cellulose is shown in formula (1), and the structural formula of product 1 is shown in formula (2).

[0026]

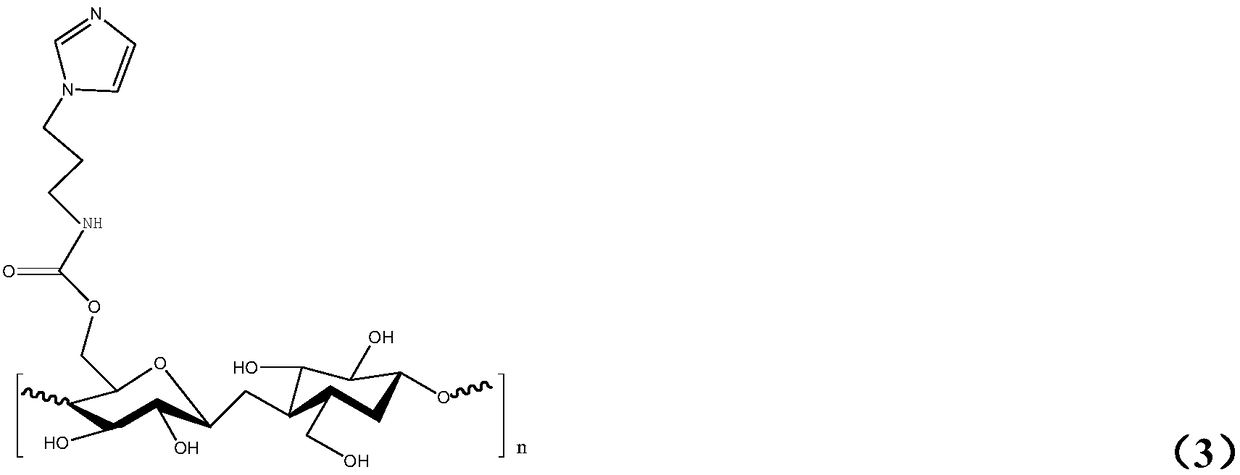

[0027] Step 2: Disperse the product 1 in DMSO again, immerse the product 1 in DMSO, and stir with a certain amount of 1-3-aminopropylimidazole at 40-50°C for 24-36 hours to obtain the product 2. Product 2 was washed three times with DMSO and then three times with acetone. After the washing is completed, the liquid is filtered off, the pro...

Embodiment 1

[0037] 1.025g carbonyldiimidazole was dissolved in 6mL DMSO, 0.5g bacterial cellulose was placed in the mixed liquid, the mixture was stirred at 40°C for 24h, and the liquid was filtered off to obtain product 1. Product 1 was washed three times with DMSO. The product 1 was dispersed in 20 mL DMSO again, 0.75 mL 1-3-aminopropylimidazole was added and stirred at 40° C. for 24 h to obtain the product 2. Product 2 was washed three times with DMSO and then three times with acetone. After the washing was completed, the liquid was filtered off, and the product 2 was vacuum-dried at 40° C. in a vacuum oven for 12 hours. The product 2 and 20 mL of 1-chlorobutane were condensed and refluxed at a temperature of 80°C, and the reaction was completed for 24 hours to obtain the product 3. The product 3 was placed on a rotary evaporator, and the temperature was set at 45°C for 4 hours of reaction, and then the product 3 was placed in a vacuum drying oven and the temperature was set at 45°C ...

Embodiment 2

[0039] 2.05g carbonyldiimidazole was dissolved in 12mL DMSO, 1g bacterial cellulose was placed in the mixed liquid, the mixture was stirred at 40°C for 24h, and the liquid was filtered off to obtain product 1. Product 1 was washed three times with DMSO. Product 1 was dispersed again in 40mL DMSO, and 1.5mL 1-3-aminopropylimidazole was stirred at 40°C for 24h to obtain product 2. Product 2 was washed three times with DMSO and then three times with acetone. After the washing was completed, the liquid was filtered off, and the product 2 was vacuum-dried at 40° C. in a vacuum oven for 12 hours. The product 2 and 40mL 1-chlorobutane were condensed and refluxed at a temperature of 80°C, and the reaction was completed for 24 hours to obtain the product 3. The product 3 was placed on a rotary evaporator, set the temperature at 45°C and reacted for 4 hours, and then placed the product 3 in a vacuum drying oven at a set temperature of 45°C for 12 hours to obtain the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com