A low-voc halogen-free flame-retardant polyolefin cable material for locomotives

A technology for polyolefin cable materials and locomotives, which is applied to circuits, electrical components, organic insulators, etc., can solve problems such as lack of compatibility, scratch-and-scratch DC stability, and index exceeding, and achieve improved compatibility, Improves the effect of anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

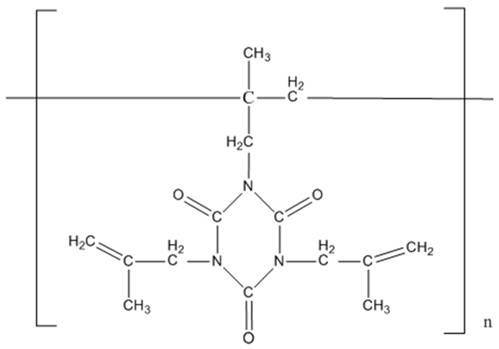

Method used

Image

Examples

Embodiment 1~3

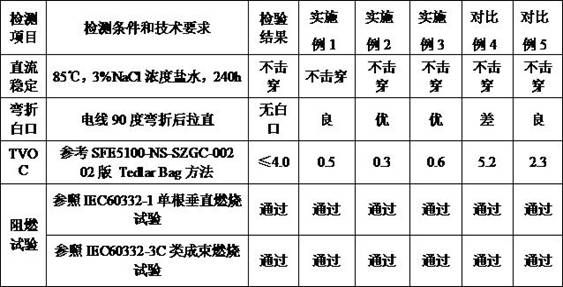

[0056] Examples 1-3: A low-VOC halogen-free flame-retardant polyolefin cable material for locomotives, which consists of the following components. For comparison, comparative examples 4-5 are also given in Table 1, as shown in Table 1:

[0057] Table 1

[0058]

[0059] The preparation process comprises the following steps:

[0060] Step 1: Mix the polyolefin base material, compatibilizer and 100 parts of flame retardant according to the weight of the formula in a high-speed mixer for 30-50 seconds at high speed, and then mix, plasticize and granulate through a twin-screw granulator. The processing temperature is: conveying section 120-130°C, melting section 140-155°C, mixing section 150-160°C, exhaust section 155-165°C, homogenizing section 155-165°C, machine head 160-170°C;

[0061] Step 2: Add the above materials to the halogen-free flame retardant (minus 100 parts, already added in the first step) measured by formula weight, coupling agent, zinc oxide, silicone masterb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com