Coal chemical industry pyrolysis-gasification coupling integrated poly-generation system

A pyrolysis gasification and coupling system technology, applied in the field of coal chemical industry, can solve the problems of low energy utilization efficiency and difficult utilization of pyrolysis semi-coke, maximize utilization efficiency and economic benefits, and adapt to changes in high value-added market demand The effect of reducing the process flow and investment operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

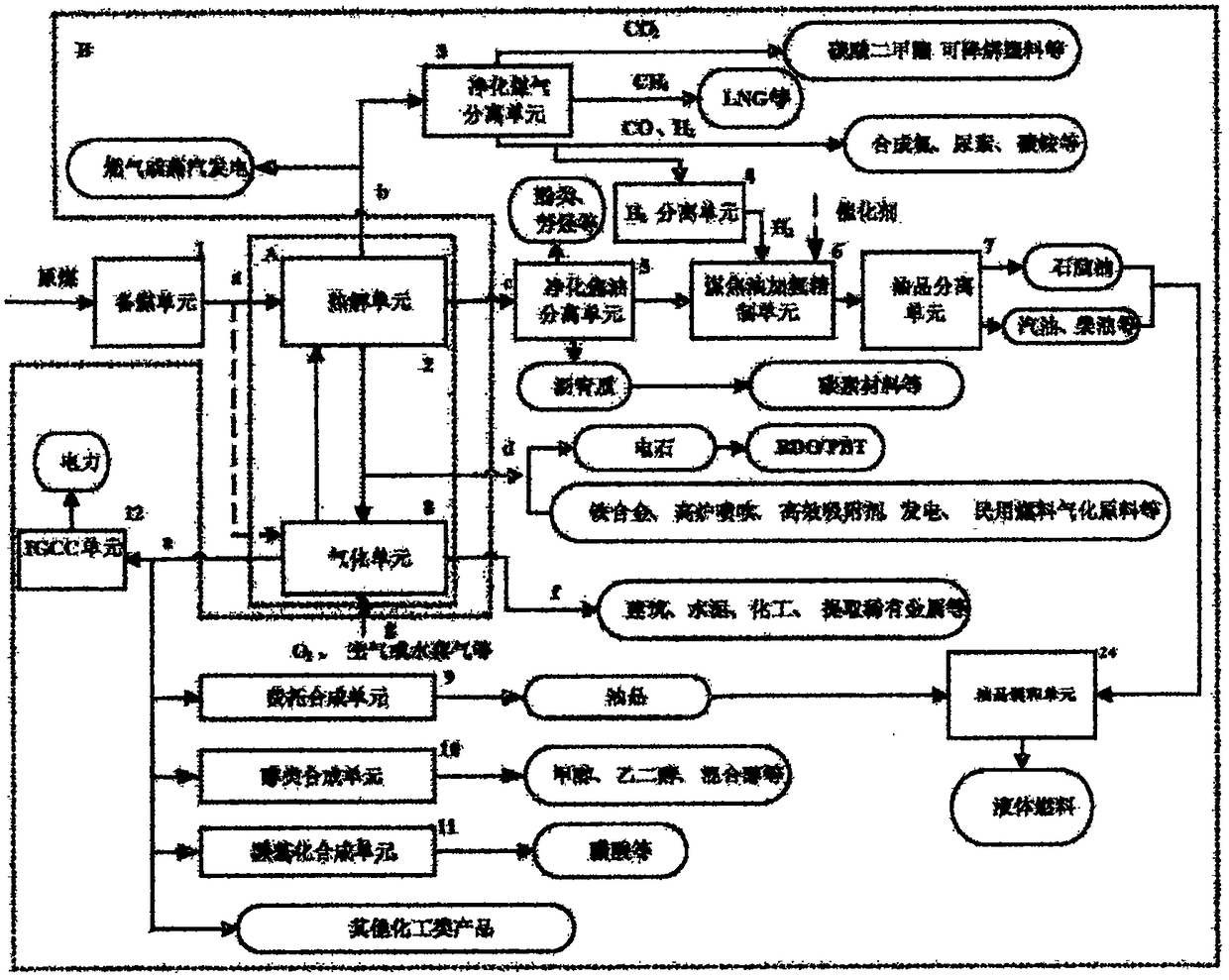

[0024] Such as figure 1 As shown, the present invention includes a coal preparation unit 1, a pyrolysis-gasification coupling system A and a polygeneration system B.

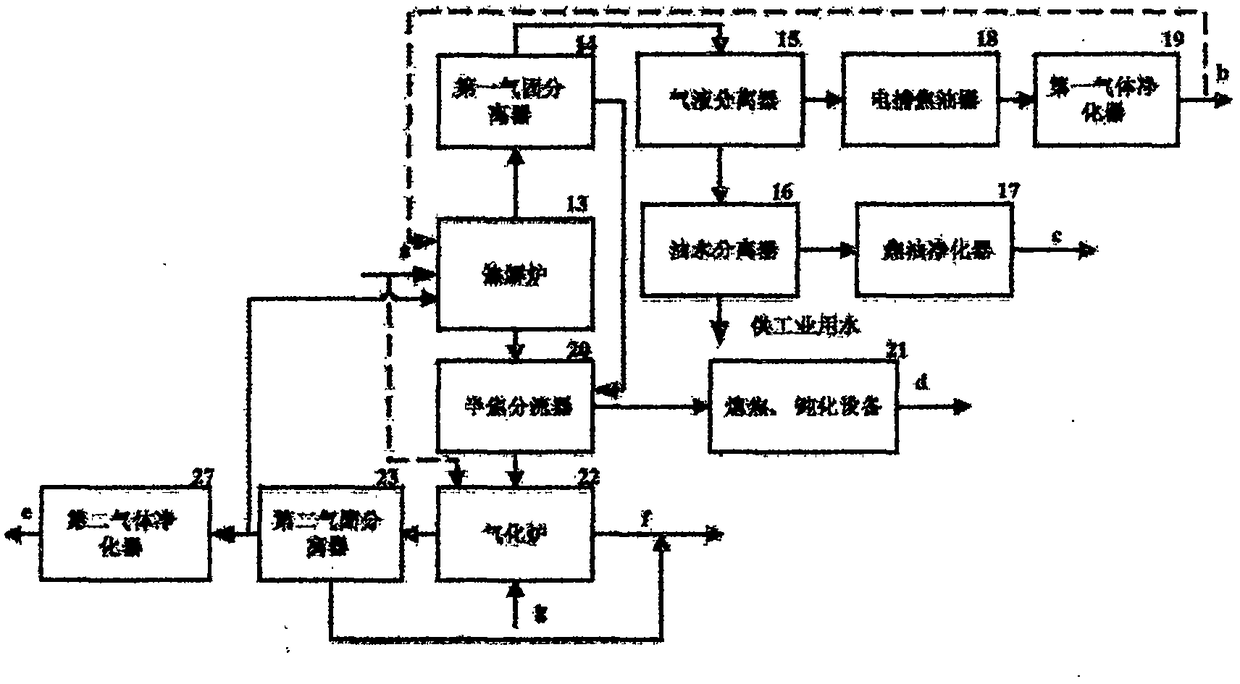

[0025] The pyrolysis-gasification coupling system A includes a pyrolysis unit 2 and a gasification unit 8 coupled together, wherein the pyrolysis unit is as attached figure 2 As shown, it includes a pyrolysis furnace 13, a first gas-solid separator 14, a gas-liquid separator 15, an oil-water separator 16, a tar purifier 17, an electric tar catcher 18, a first gas purifier 19, and a semi-coke splitter 20 and coke quenching passivation equipment 21; the gasification unit includes a gasification furnace 22, a second gas-solid separator 23 and a second gas purifier 27. between the parts figure 2 As shown, they are connected through pipelines. Specifically, the two output ends of the pyrolysis furnace 13 are respectively connected to the input end of the first gas-solid separator 14 and the input end of the semi-...

Embodiment 2

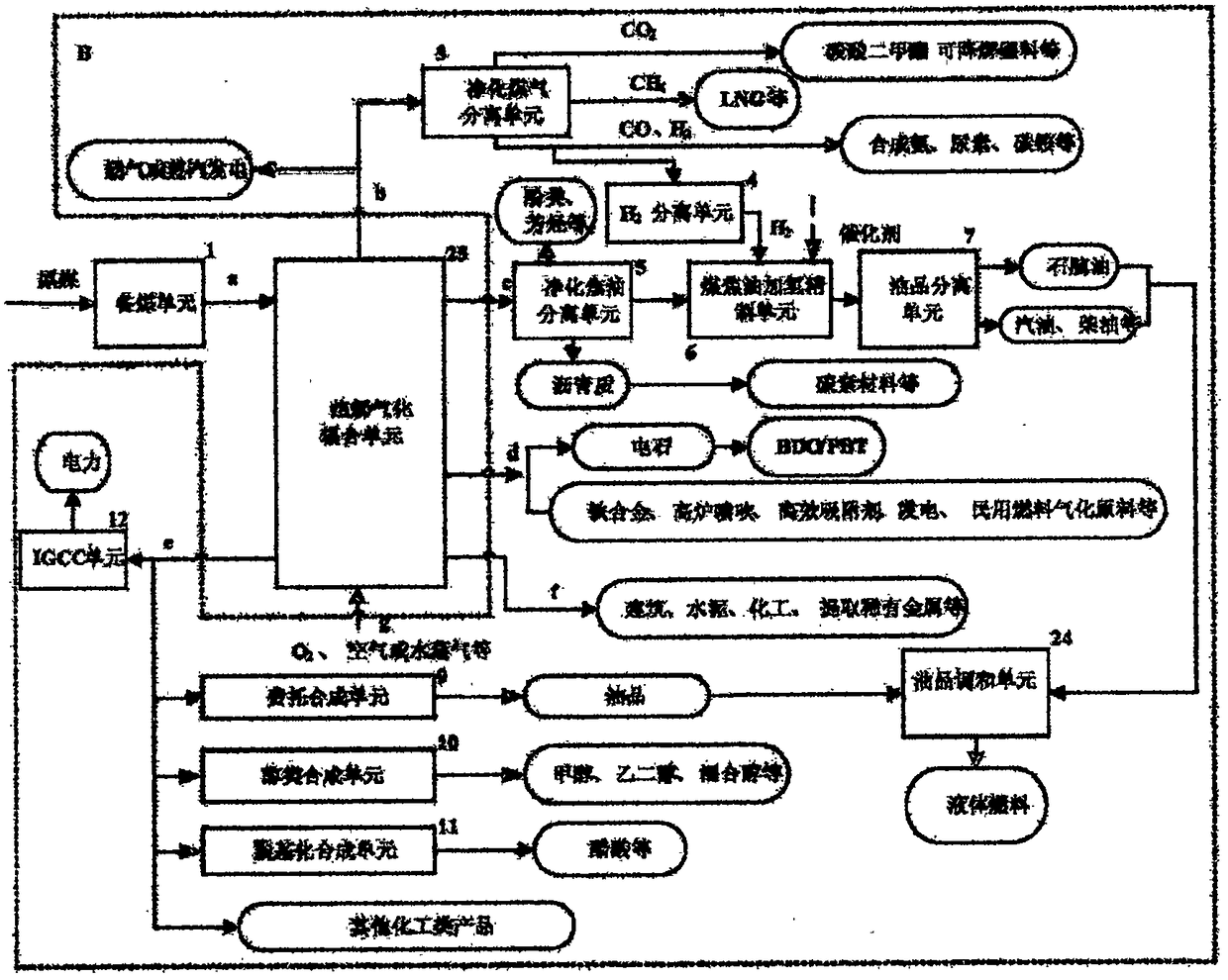

[0042] Such as image 3 As shown, in order to make the device simpler, easier to deploy and control, the present invention will attach figure 1 The pyrolysis furnace 13 of the middle pyrolysis unit 2, the gasification furnace 22 and the semi-coke splitter 20 of the gasification unit 8 are integrated into one device to realize the coupling of raw coal pyrolysis and gasification. It includes coal preparation unit 1, pyrolysis gasification coupling unit 25 and polygeneration system B.

[0043] Pyrolysis gasification coupling unit 25 as attached Figure 4 As shown, it includes a pyrolysis gasifier 26, a first gas-solid separator 14, a gas-liquid separator 15, an oil-water separator 16, a tar purifier 17, an electric tar catcher 18, a first gas purifier 19, and a coke quenching passivation equipment 21 , a second gas-solid separator 23 and a second gas purifier 27 . between the parts Figure 4 Shown are connected by pipelines, and the output end of the top of the pyrolysis sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com