Film material lateral piezoelectric coefficient testing model based on multi-layer cantilever beam and method thereof

A technology of piezoelectric coefficient and thin-film material, which is applied in the field of online testing of micro-electromechanical system material parameters, can solve problems such as the complexity of the solution process, the accuracy that cannot meet the MEMS production process, and the measurement speed of the transverse piezoelectric coefficient that cannot meet the MEMS production process. , to achieve the effect of simple test model, easy-to-operate test method, repeatability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

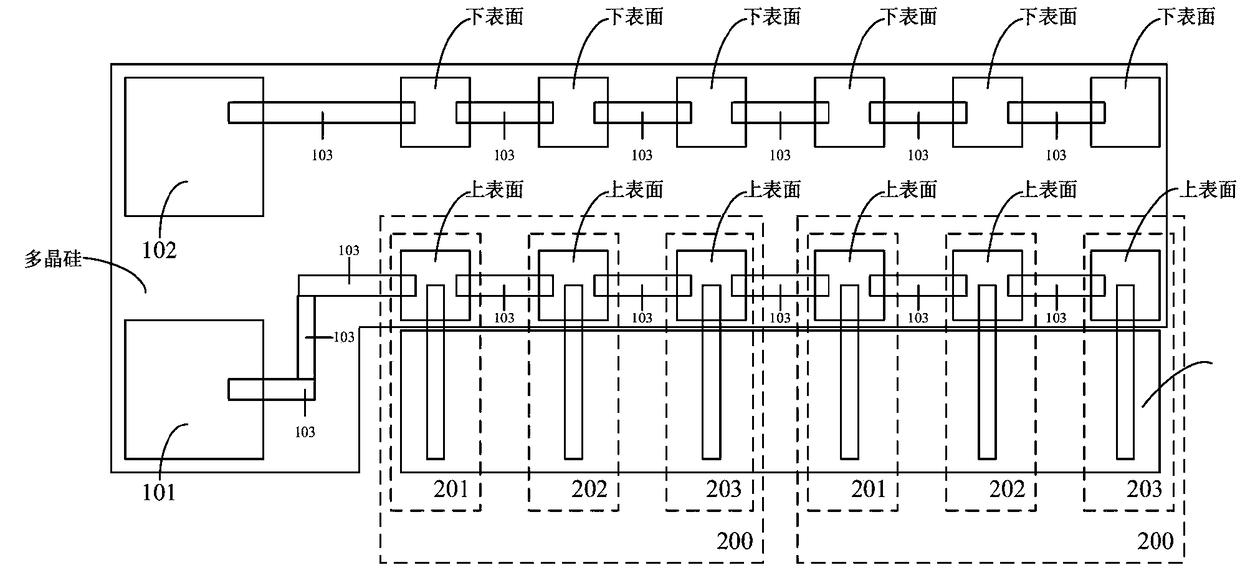

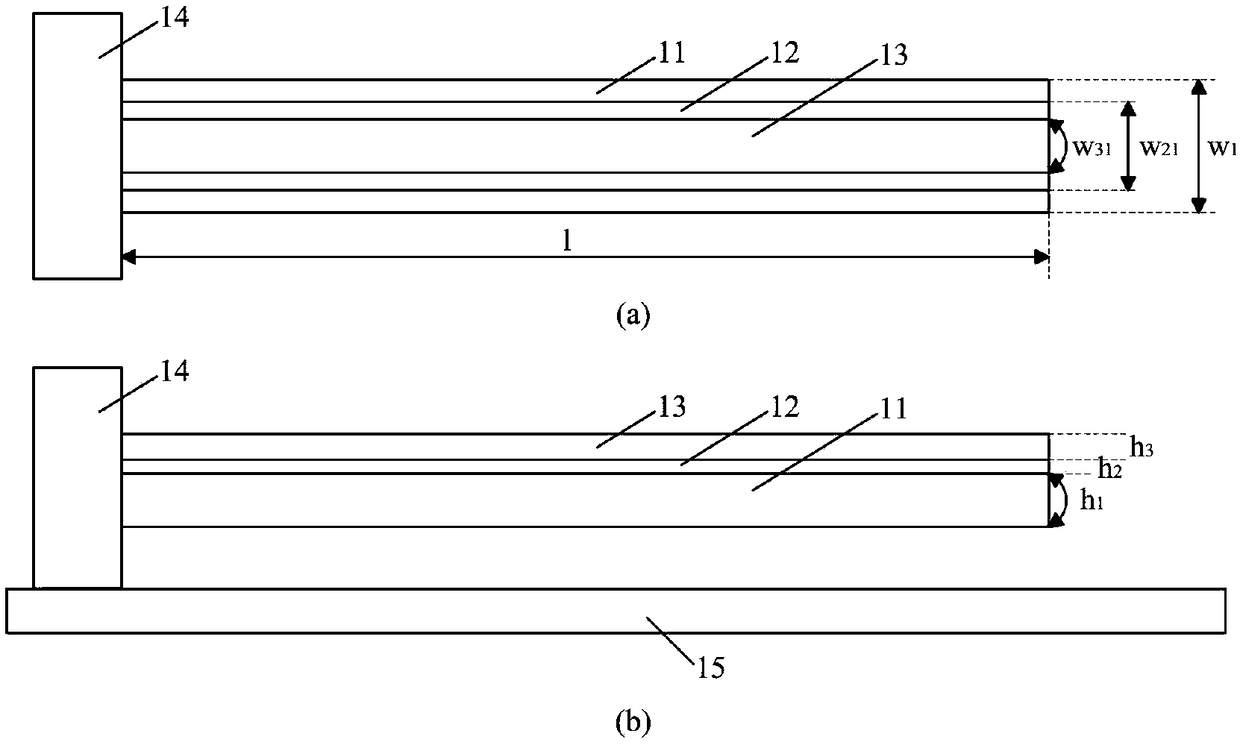

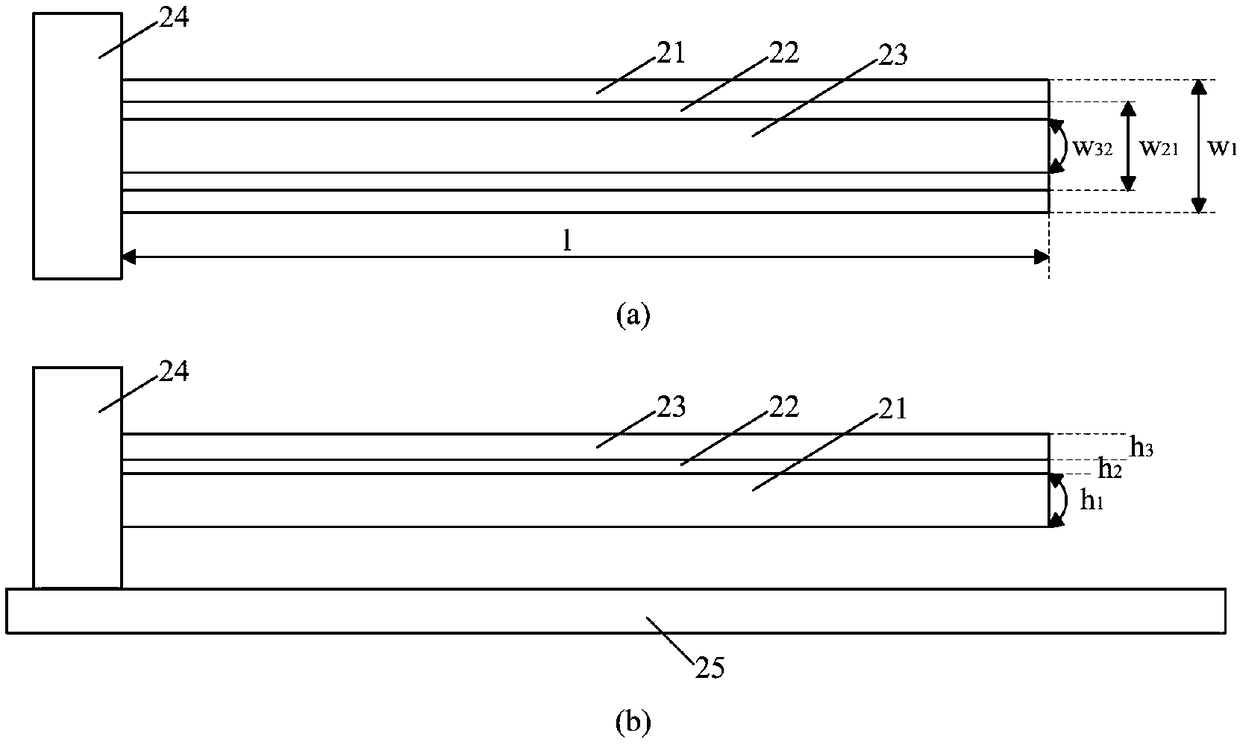

[0026] figure 2 is a structural schematic diagram of the first three-layer cantilever beam 201, wherein figure 2 (a) is a plan view, figure 2 (b) is a side view. The first three-layer cantilever beam 201 includes: a bottom layer 11 , a middle layer 12 , a top layer 13 , an anchor region 14 and a substrate 15 . The anchor region 14 is fixed on the substrate 15, and other regions except the anchor region 14 are suspended to form a cantilever beam structure. The bottom layer 11 is a polysilicon layer, the middle layer 12 is a piezoelectric film material layer, and the top layer 13 is a metal layer. The length of the first three-layer cantilever beam 201 is l. The thickness of the bottom layer 11 of the first three-layer cantilever beam 201 is h 1 , the width is w 1 ; The thickness of the middle layer 12 of the first three-layer cantilever beam 201 is h 2 , the width is w 21 ; The thickness of the top layer 13 of the first three-layer cantilever beam 201 is h 3 , the w...

specific Embodiment 2

[0032] A kind of three-layer cantilever beam constituting the test model 200 is manufactured by basic micro-electromechanical processing technology, and the specific steps are as follows:

[0033] step 1:

[0034] A layer of oxide layer is grown on a 400 μm silicon substrate, and a layer of polysilicon bottom layer is grown on it, and a layer of photoresist PSG is deposited; it is annealed in an environment filled with argon and kept at 1050°C for 1 hour, The polysilicon is doped; the PSG is then wet etched away.

[0035] Step 2:

[0036] A 0.2μm oxide layer is grown, and a positive photoresist is spin-coated on it, and the pattern of the first mask plate PADOXIDE is copied onto the photoresist; the exposed part of the photoresist is removed and wet-etched Etch away unwanted oxide layers.

[0037] Step 3:

[0038] Reactive sputtering method (Reactive Sputtering) is used to sputter the intermediate piezoelectric material AlN; spin-coat positive photoresist on it, and the pa...

specific Embodiment 3

[0047] Using the test model 200 and the instrument, the Young's modulus of each layer material of the cantilever beam is extracted by the resonance frequency method. The step of extracting Young's modulus includes: using an instrument to measure the first-order resonance frequency, and obtaining the Young's modulus through analytical calculation.

[0048] Step 101: Use an instrument to measure the first-order resonance frequency, including: measuring the first-order resonance frequency f of the first three-layer cantilever beam 201 1 , measuring the first-order resonant frequency f of the second and third layer cantilever beams 202 2 and measure the first-order resonant frequency f of the third three-layer cantilever beam 203 3 ,details as follows:

[0049] Step 101-1: Use a digital holographic microscope (DHM-R2200, Lyncée Tec SA, Switzerland) to determine whether the first three-layer cantilever 201, the second three-layer cantilever 202, and the third three-layer cantilev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com