Manufacturing method of double-sided multi-step cavity LTCC substrate

A manufacturing method and multi-step technology, applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve problems such as short interconnection paths, parasitic interference of radio frequency signals, and affecting circuit performance, so as to improve electrical performance, Effects of improving performance and ensuring lamination accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

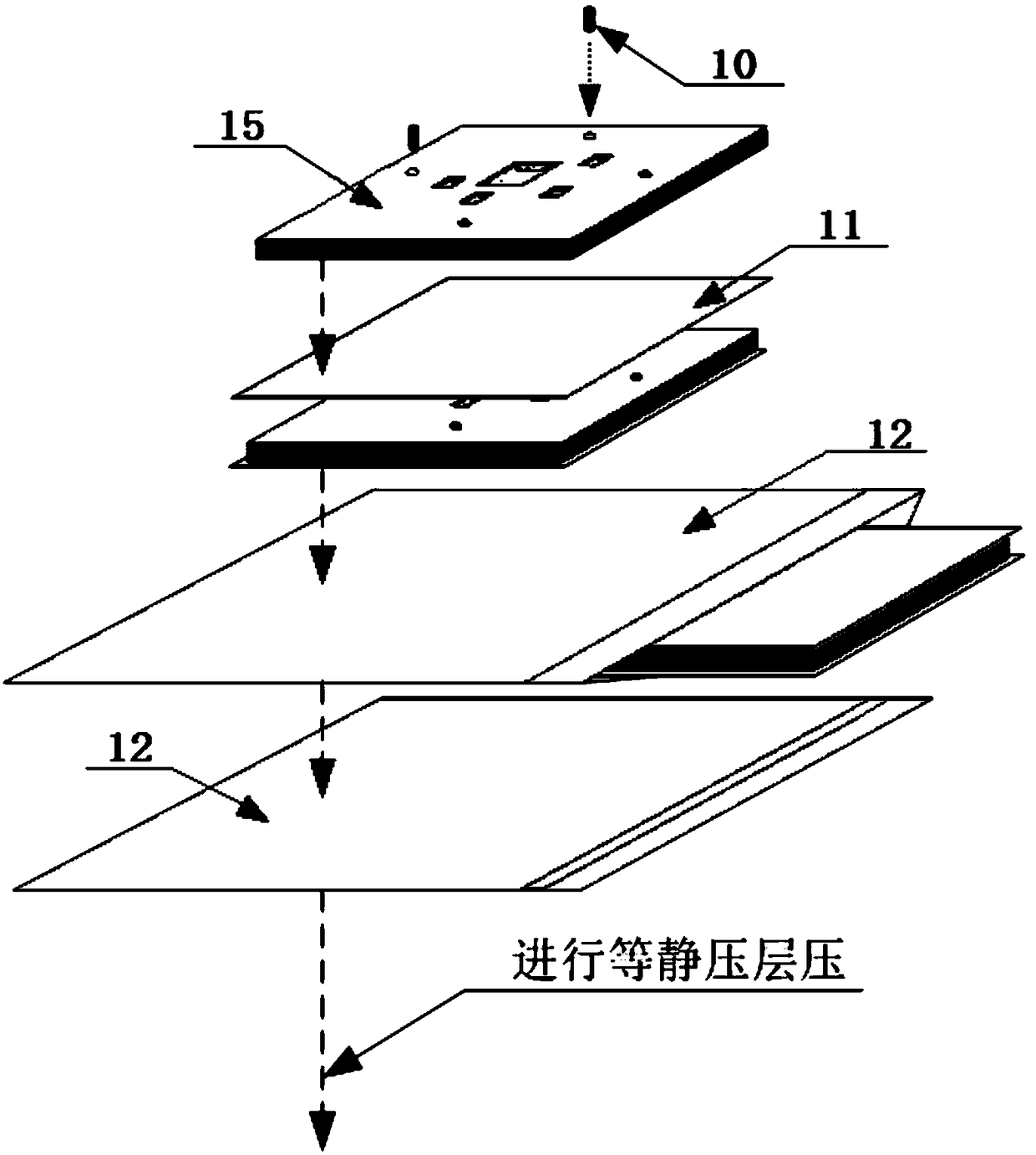

[0037] The present invention is described in further detail below in conjunction with accompanying drawing:

[0038] The specific manufacturing method is as follows:

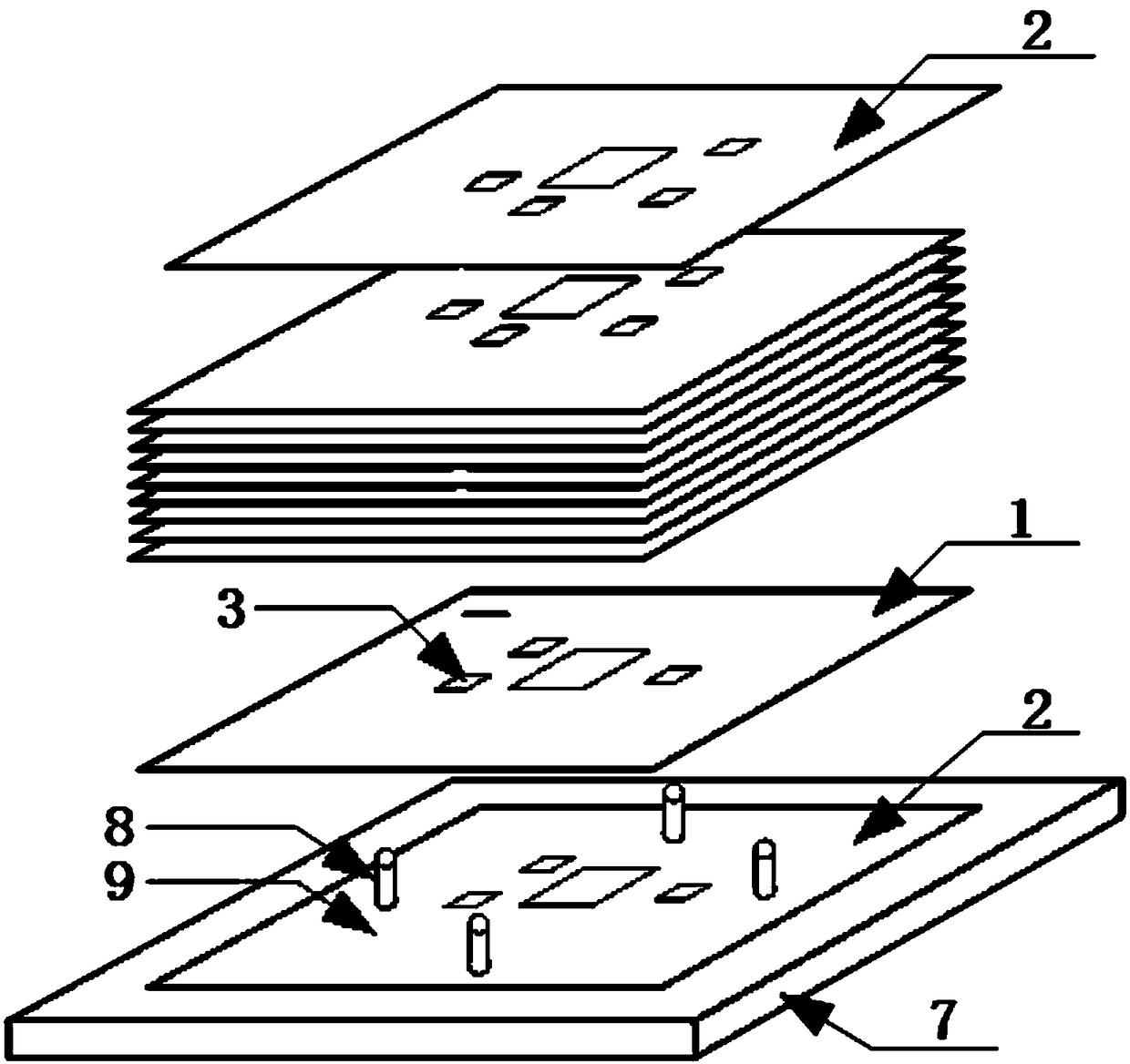

[0039] The first step: if figure 1 As shown, the green ceramic sheet 1 is pre-dried, punched and opened, filled and printed with conductors, and dried with metal conductors according to the traditional process.

[0040] Part 2: Release treatment of green ceramic sheet 1;

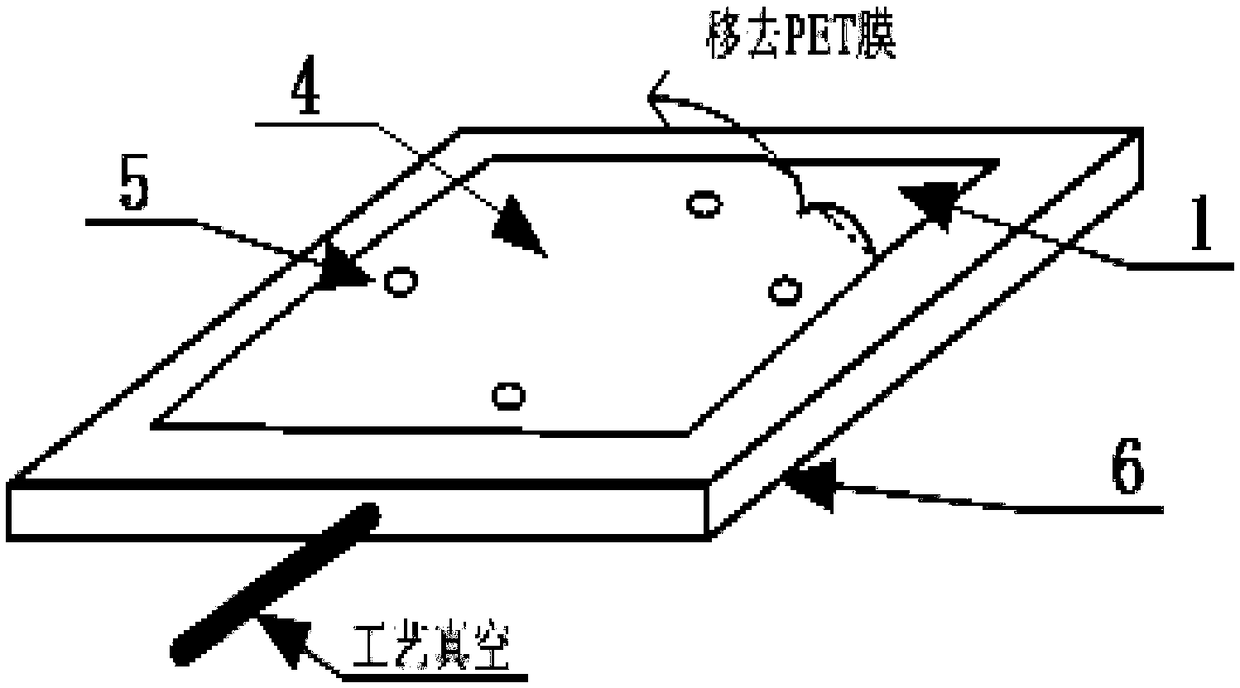

[0041] Such as figure 2 As shown, the green ceramic sheet 1 is adsorbed on the suction cup 6 by process vacuum during demoulding, and then the PET film 4 of the green ceramic sheet 1 is removed, and then the adsorption is cancelled, and the green ceramic sheet 1 is removed.

[0042] When the suction cup 6 absorbs the green ceramic sheet 1, the position of the cavity 3 of the green ceramic sheet 1 should be staggered to prevent the suction force from decreasing.

[0043] The third step: 1 stack of green ceramic sheets is used as the substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com