Manganese dioxide/corn straw nanomaterial and preparation method and application thereof

A corn stalk, manganese dioxide technology, applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc., to avoid centrifugation or filtration operations, excellent purification effect, and simplify the purification process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) The corn stalks were manually peeled off from the dry corn stalks, washed ten times with deionized water, dried naturally, and cut into small pieces of 10 mg;

[0027] (2) Weigh 0.07915 g of potassium permanganate into a clean beaker, dissolve it and dilute to 500 mL, and prepare a 1 mmol / L potassium permanganate solution.

[0028] (3) Take 4 pieces of 40 mg corn stalks in 20 mL of 1 mmol L -1 In the potassium permanganate solution, react 60 min under the condition of continuous stirring at 300 rpm;

[0029] (4) The reacted corn stalks were taken out, washed ten times with deionized water, and dried naturally to obtain the manganese dioxide / corn stalk nanomaterials.

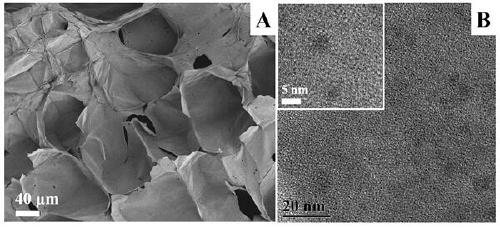

[0030] figure 1 For the morphology characterization of the material by scanning electron microscope (JSM-7500F, JEOL) (A) and the morphology characterization of the material after thermal alkali treatment and filtration by transmission electron microscope (Tecnai-G20, FEI, USA) (B) . The A graph ...

Embodiment 2

[0039] (1) The corn stalks were manually peeled off from the dry corn stalks, washed ten times with deionized water, dried naturally, and cut into small pieces of 10 mg;

[0040] (2) Weigh 0.07915 g of potassium permanganate into a clean beaker, dissolve it and dilute to 500 mL, and prepare a 1 mmol / L potassium permanganate solution.

[0041] (3) Take 6 pieces of 60 mg corn stalks and place them in 20 mL of 1 mmol / L potassium permanganate solution, and react for 90 min under the condition of continuous stirring at 200 rpm;

[0042] (4) The reacted corn stalks were taken out, washed ten times with deionized water, and dried naturally to obtain the manganese dioxide / corn stalk nanomaterials.

Embodiment 3

[0044] (1) The corn stalks were manually peeled off from the dry corn stalks, washed ten times with deionized water, dried naturally, and then cut into small pieces of 20 mg;

[0045] (2) Weigh 0.07915 g of potassium permanganate into a clean beaker, dissolve it and dilute to 500 mL, and prepare a 1 mmol / L potassium permanganate solution.

[0046] (3) Four pieces of corn stalks totaling 80 mg were placed in 10 mL of 1 mmol / L potassium permanganate solution and reacted for 120 min under constant stirring at 300 rpm;

[0047] (4) The reacted corn stalks were taken out, washed ten times with deionized water, and dried naturally to obtain the manganese dioxide / corn stalk nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com