A method for adjusting the alignment direction of ceramic nanowires in composite materials

A composite material and arrangement direction technology, which is applied in the field of regulating the arrangement direction of ceramic nanowires in composite materials, can solve the problems of non-uniformity and inconsistency, structural damage of composite materials, harsh process conditions, etc., to solve the problem of dispersion and efficient arrangement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] Example: This scheme prepares BaTiO 3 / P(VDF-CTFE) composite material

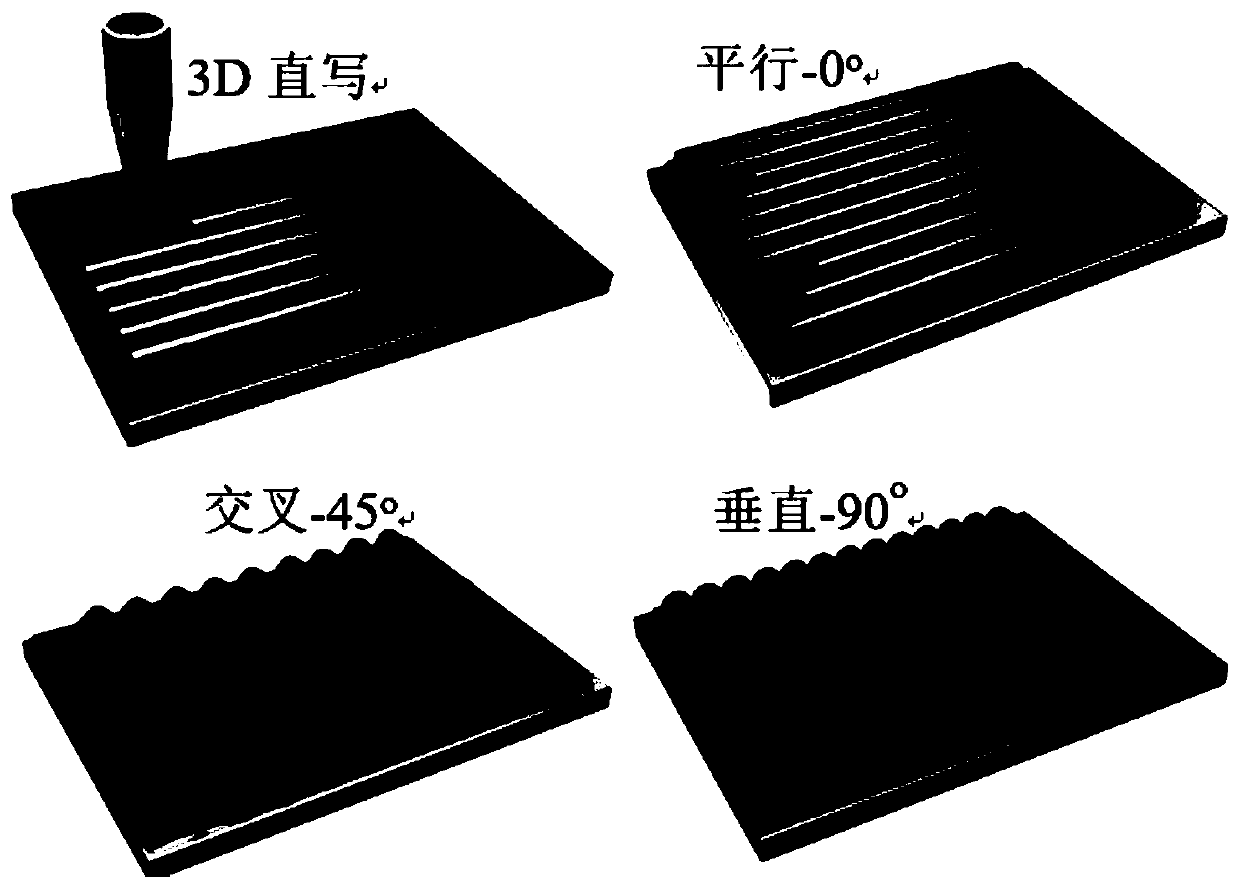

[0053] 1. In situ modification of BaTiO in step 1 3 The scheme of the nanowires is the same as that of the comparative example. Compared with the comparative example, this example adopts 3D direct writing technology to prepare the composite film, and the specific steps are as follows:

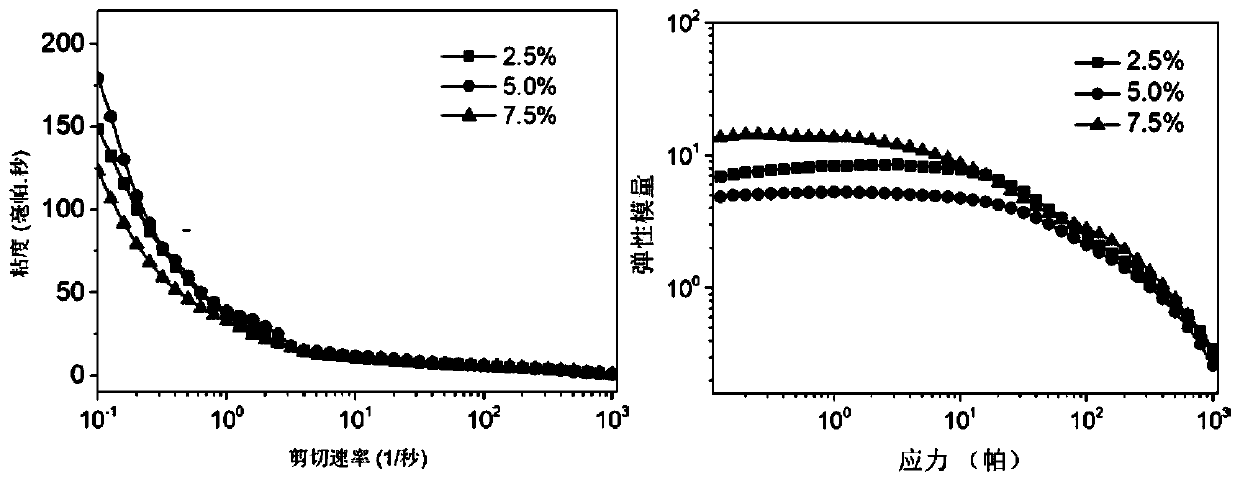

[0054] Weigh 0.0635g, 0.0866g, 0.177g, 0.274gPTFMPCS modified BaTiO 3 The nanowires were added to 12.5g of DMF solvent (the volume ratios of nanowires in the composite material were 1.5%, 2.5%, 5% and 7.5% respectively), ultrasonically dispersed for 10min, then 1.2gP(VDF-CTFE) resin was added, ultrasonically After dispersing, two days of ball milling were carried out to obtain uniformly dispersed suspension slurry, which were respectively used as four groups of examples.

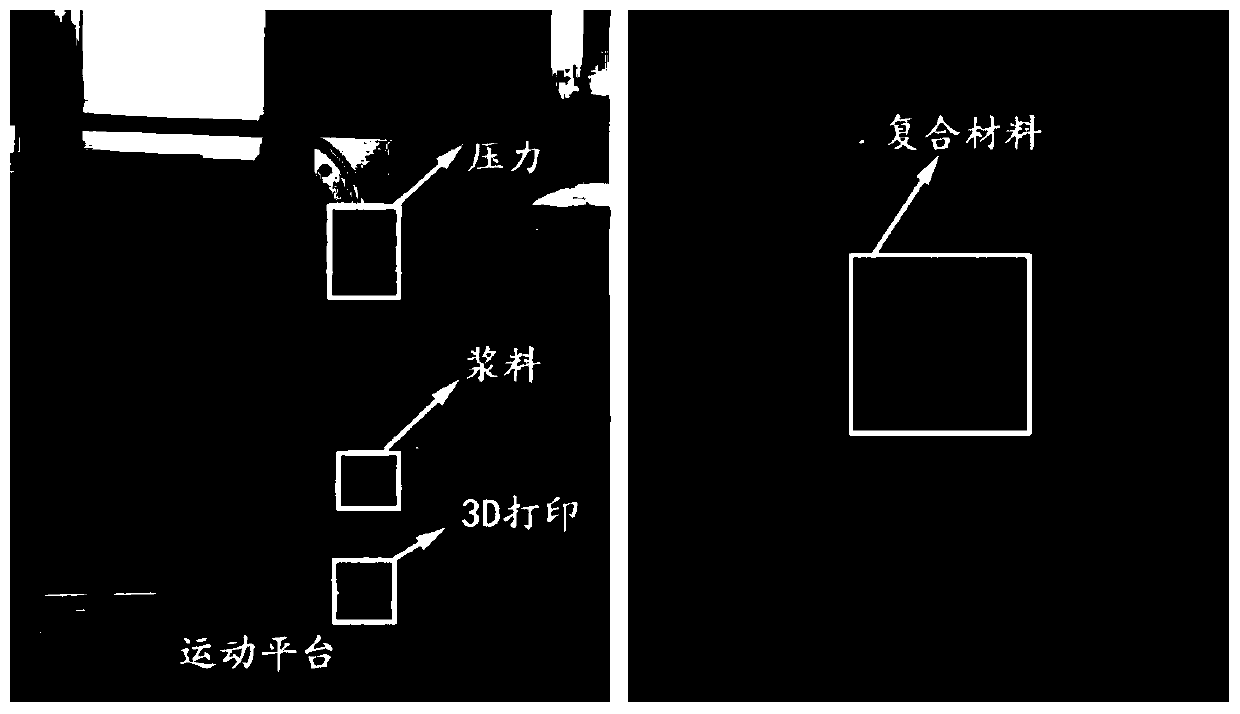

[0055] Transfer the slurry of each embodiment to the barrel, connect the air compressor to adjust the pressure, so that the slurry extrusion d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com