Strong insulating material and preparation method thereof

An insulating material and one-sided technology, applied in chemical instruments and methods, lamination, coating, etc., can solve problems affecting insulating devices, low dielectric strength, and incompatible with the development trend of miniaturization and light weight of electrical equipment, etc. Achieve the effects of improving insulation performance, improving impact resistance, and good insulation and heat conduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

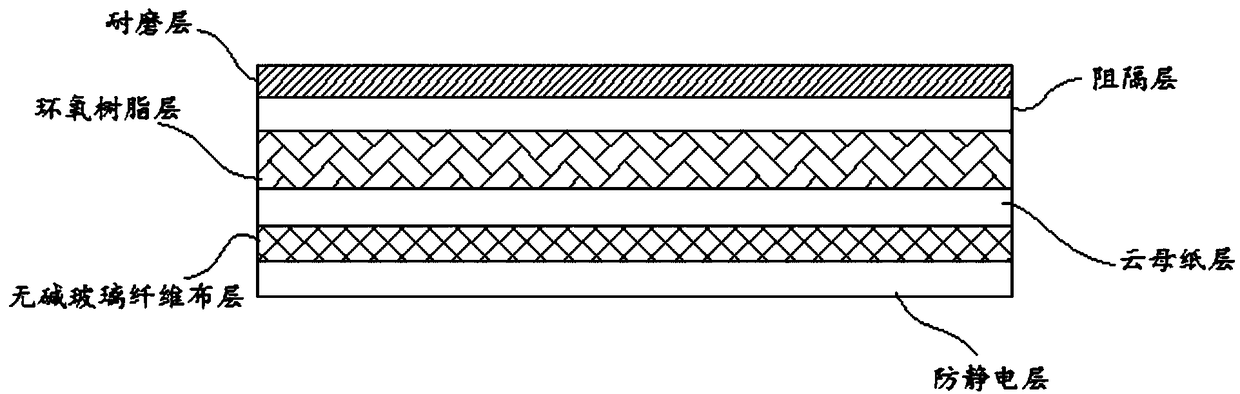

[0041] A strong insulating material such as figure 1 As shown, from top to bottom are wear-resistant layer, barrier layer, epoxy resin layer, mica paper layer, alkali-free glass fiber cloth layer and antistatic layer, and the wear-resistant layer and barrier layer are bonded by adhesive , the mica paper layer and the non-alkali glass fiber cloth layer are bonded by an adhesive, and the non-alkali glass fiber cloth layer and the antistatic layer are bonded by an adhesive;

[0042] The wear-resistant layer is a smooth insulating film with a low coefficient of friction, preferably a polytetrafluoroethylene film, and the wear-resistant layer is used as the outermost layer of the insulating material in contact with the outside world;

[0043] The barrier layer is a film material with a good effect of isolating water vapor, preferably a polyvinylidene chloride film;

[0044] The antistatic layer is used as the side in contact with the equipment that needs to be insulated;

[0045]...

Embodiment 2

[0062] A strong insulating material such as figure 1 As shown, from top to bottom are wear-resistant layer, barrier layer, epoxy resin layer, mica paper layer, alkali-free glass fiber cloth layer and antistatic layer, and the wear-resistant layer and barrier layer are bonded by adhesive , the mica paper layer and the non-alkali glass fiber cloth layer are bonded by an adhesive, and the non-alkali glass fiber cloth layer and the antistatic layer are bonded by an adhesive;

[0063] The wear-resistant layer is a smooth insulating film with a low coefficient of friction, preferably a polytetrafluoroethylene film, and the wear-resistant layer is used as the outermost layer of the insulating material in contact with the outside world;

[0064] The barrier layer is a film material with a good effect of isolating water vapor, preferably a polyvinylidene chloride film;

[0065] The antistatic layer is used as the side in contact with the equipment that needs to be insulated;

[0066]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com