Low-heat-release high-temperature-resistant irradiation cross-linked polyolefin insulating material

A cross-linked polyolefin, high temperature-resistant technology, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve problems such as fire extinguishing, difficulty in escaping and restoring work, a large amount of corrosive and toxic gases, and secondary hazards , to achieve the effect of increasing the degree of hardness and compactness, reducing the release of smoke, and reducing the rate of smoke release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0033] Examples 1~3: A radiation cross-linked polyolefin insulating material with low heat release and high temperature resistance. Preparation method: Weigh the raw materials according to the formula, mix them in a high-speed mixer for 5 to 10 minutes, and knead through an internal mixer , The kneading temperature is 140~160℃; then through the twin-screw extruder extrusion granulation, the extrusion temperature is 140~160℃.

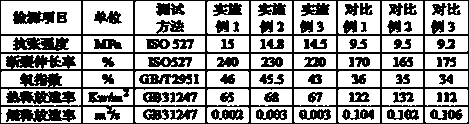

[0034] The polyolefin insulating material is composed of the following parts by weight, as shown in Table 1:

[0035] Table 1

[0036] ;

[0037] The TPO is a blend of rubber with a soft segment content greater than 20% and a hard segment polyolefin. The thermoplastic polyolefin elastomer has a density of 0.87 to 0.89 g / cm3 and melts at 230°C. Melting index is 0.2~1g / 10min;

[0038] The density of the POP is 0.92g / cm3, and the melt index is 1g / 10min (190°C);

[0039] The EVM is an ethylene-vinyl acetate copolymer with a density of 0.9~1g / cm3 and a VA content of ...

Embodiment 1

[0045] The TPO of Example 1 and Example 2 is CA-02A produced by Basel Company in the Netherlands, and the TPO of Example 3 is CA-10A.

[0046] The POP of Example 1 is 8102 produced by Saudi Arabia Company, the POP of Example 2 is 8108, and the POP of Example 3 is 8402.

[0047] The EVM of Example 1 is EVM500 produced by the German LANXESS Chemical Company, the EVM600 of Example 2 is EVM600, and the EVM700 of Example 3 is EVM700.

[0048] The aluminum hydroxide of Examples 1 to 3 is HW-F-1 produced by Shandong Pengfeng Aluminum.

[0049] The molecular sieve in the example is a 3A molecular sieve produced by Dalian Haixin Chemical, the example 2 is a 4A molecular sieve, and the example 3 is a 5A molecular sieve.

[0050] The organopolysiloxane coupling agent of Example 1 and Example 2 was ZS-100 produced by Yangzhou Zhongsen Technology Co., Ltd., and the organopolysiloxane coupling agent of Example 3 was ZS-200.

[0051] The naphthenic rubber oil in Examples 1 to 3 is K10A produced by Chin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com