A kind of conductive silicone rubber plate and preparation method thereof

A technology of rubber sheet and conductive silicon, applied in the field of silicone rubber, can solve the problems of poor conductivity and instability of conductive silicone rubber, and achieve the effect of improving conductivity, low resistivity and good resistance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

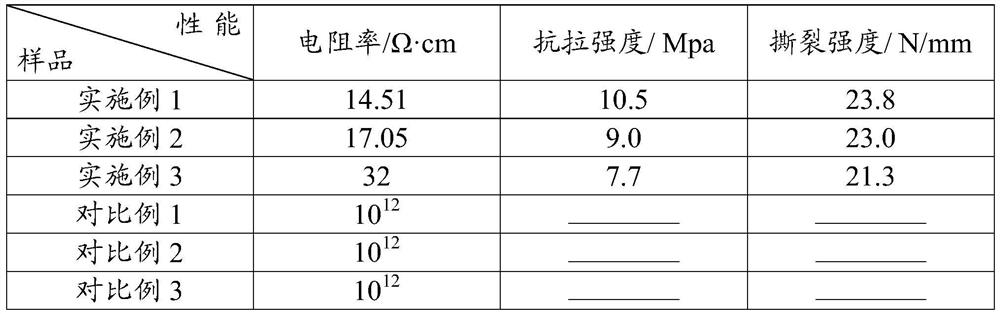

Examples

Embodiment 1

[0025] A conductive silicone rubber plate is composed of the following raw materials in parts by weight:

[0026] 100 parts of methyl vinyl silicone rubber, 72 parts of graphite, 2 parts of nano-titanium dioxide with a particle size of 100nm, 1.5 parts of vulcanizing agent 2,4-dichlorobenzoyl peroxide, 35 parts of stainless steel fibers with a length of 5mm, 36 8 parts of carbon fiber cloth woven with 12k carbon fiber precursors, 44 parts of aluminum silicate fiber cloth with a thickness of 2mm.

[0027] The preparation method of conductive silicone rubber plate in the present embodiment comprises the following steps:

[0028] Weigh 2.85kg of the material methyl vinyl silicone rubber in the mixing process according to the above parts by weight, 2.05kg of graphite, 0.05kg of nano-titanium dioxide, 0.04kg of vulcanizing agent 2,4-dichlorobenzoyl peroxide, and 9.4g of steel fiber, 2.2g of carbon fiber cloth, 12g of aluminum silicate fiber cloth;

[0029] Put the methyl vinyl si...

Embodiment 2

[0032] A conductive silicone rubber plate is composed of the following raw materials in parts by weight:

[0033] 100 parts of methyl vinyl silicone rubber, 65 parts of graphite, 1.5 parts of nano-titanium dioxide with a particle size of 60nm, 2 parts of vulcanizing agent DCP (dicumyl peroxide), 30 parts of stainless steel fibers with a length of 6mm, 24 pieces of 12k There are 8 parts of carbon fiber cloth woven with carbon fiber precursors, and 44 parts of aluminum silicate fiber cloth with a thickness of 3 mm.

[0034] The preparation method of conductive silicone rubber plate in the present embodiment comprises the following steps:

[0035] Take by weighing 2.85kg of the material methyl vinyl silicone rubber in the mixing process, graphite 1.85kg, nano-titanium dioxide 0.04kg, vulcanizing agent DCP (dicumyl peroxide) 0.05kg and the steel fiber of the vulcanization process according to the above parts by weight The amount is 7.8g, the carbon fiber cloth is 2.2g, and the al...

Embodiment 3

[0039] A conductive silicone rubber plate is composed of the following raw materials in parts by weight:

[0040] 100 parts of methyl vinyl silicone rubber, 60 parts of graphite, 2 parts of nano-titanium dioxide with a particle size of 60nm, 1.5 parts of vulcanizing agent DCP (dicumyl peroxide), 22 parts of stainless steel fibers with a length of 5mm, and 36 pieces of 12k carbon fibers The raw silk woven carbon fiber cloth is 8 parts, and the aluminum silicate fiber cloth with a thickness of 2mm is 44 parts.

[0041] The preparation method of conductive silicone rubber plate in the present embodiment comprises the following steps:

[0042] Take by weighing 2.85kg of material methyl vinyl silicone rubber in the mixing process, graphite 1.71kg, nano-titanium dioxide 0.05kg, vulcanizing agent DCP (dicumyl peroxide) 0.04kg and steel in the vulcanization process according to the above parts by weight. Fiber 6.0g, carbon fiber cloth 2.2g, aluminum silicate fiber cloth 12g;

[0043...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com