Method for preparing hydrocarbon fuel from grease raw materials

A technology for oil and hydrocarbon fuels, which is applied in the field of preparing hydrocarbon fuels from oil and fat raw materials, can solve problems such as poor low temperature fluidity, and achieve the effects of low freezing point, simplified process flow, and good isomeric selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

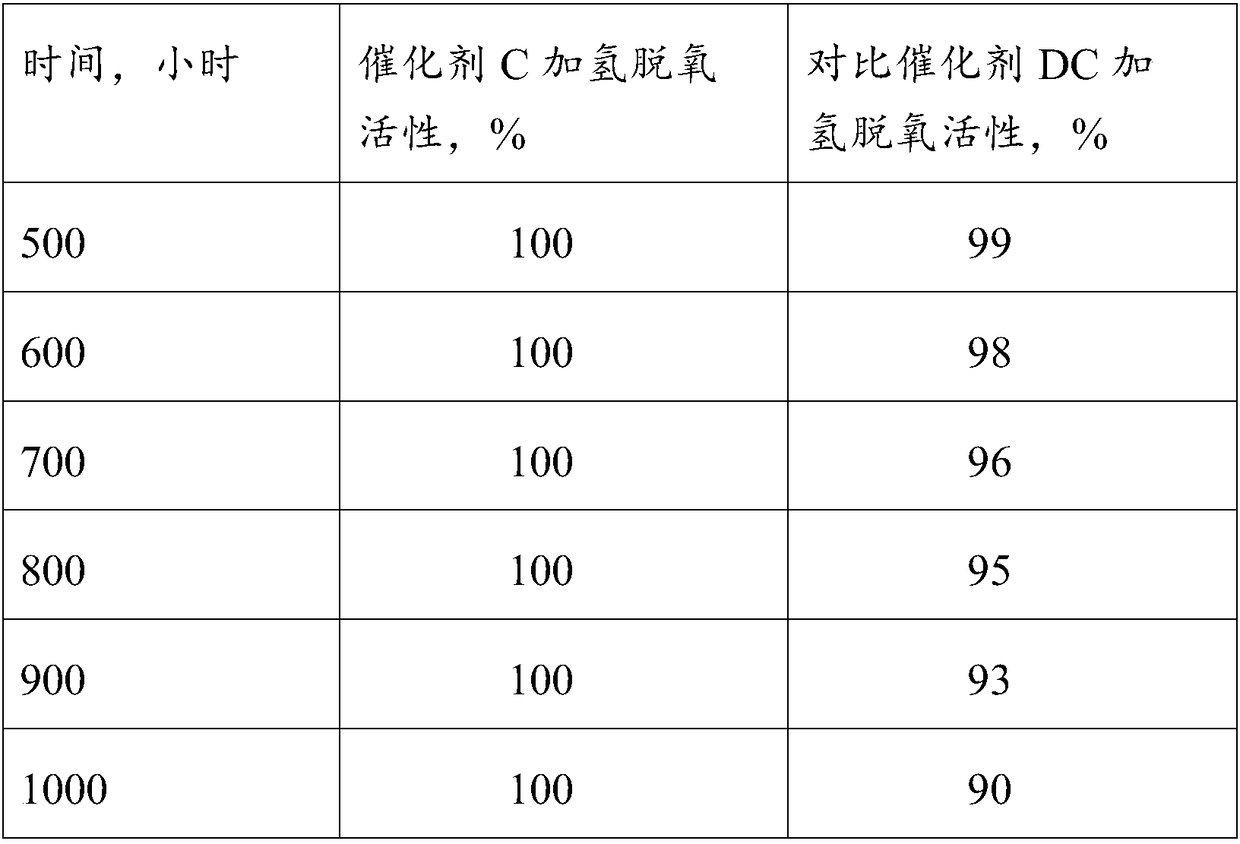

[0047] Preparation Example 1 Preparation of Hydrotreating Catalyst

[0048] Weigh 500 grams of pseudo-boehmite (produced from Changling Catalyst Factory), extrude it into a clover-shaped strip with a circumcircle diameter of 1.6 mm, and dry it at 120° C. for 6 hours. Take 300 grams of it, and process it for 6 hours at a temperature of 600° C. at a volume ratio of air to water vapor of 1:0.6, a gas flow rate of 1.0 standard cubic meters / kg.hour, and a temperature of 600° C. to obtain the carrier S .

[0049] Weigh 100 grams of carrier S, impregnate with 86 ml of aqueous solution containing 5.8 grams of ammonium paramolybdate, 29.7 grams of nickel nitrate and 53.4 grams of ammonium metatungstate for 2 hours, dry at 120°C for 3 hours, and roast at 450°C for 4 hours to obtain hydrogenation Treat Catalyst C. MoO in the catalyst 3 , NiO and WO 3 The weight contents are respectively 2.8%, 4.4% and 25.7%.

Embodiment 1

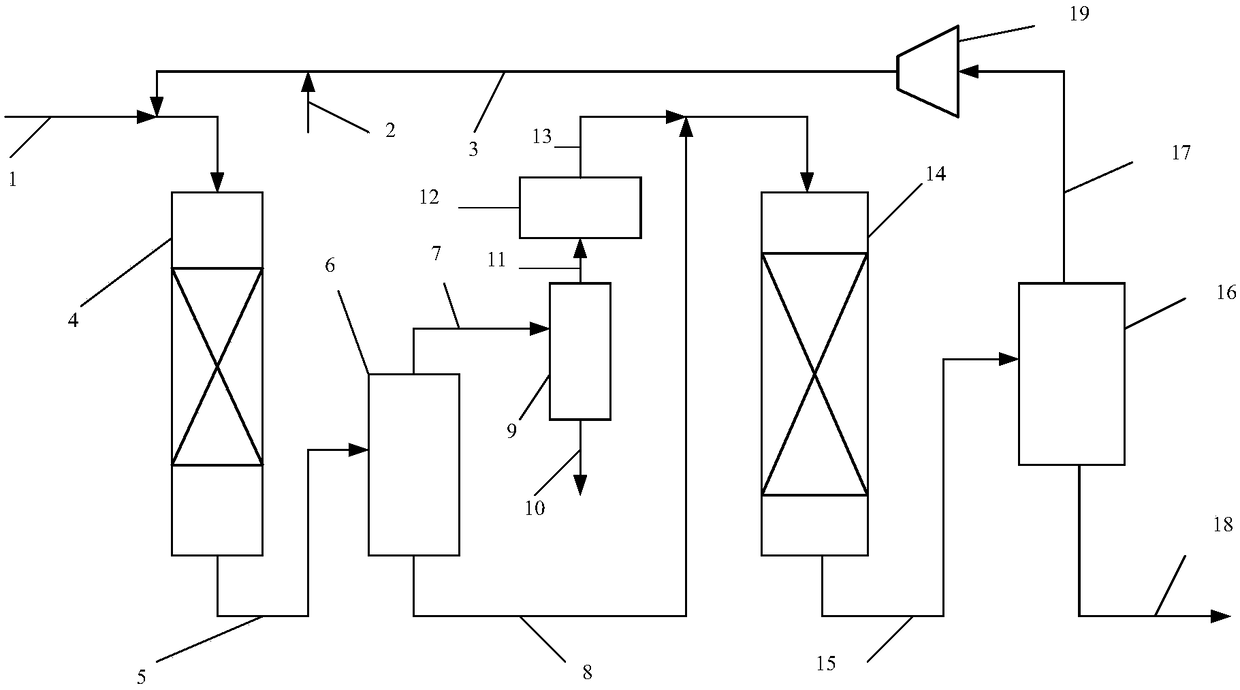

[0056] In this embodiment, palm oil is used as the oil raw material, and the main properties of palm oil are shown in Table 2. figure 1 The process flow shown. 100mL of hydrotreating catalyst C is installed in the hydrotreating reactor. After hydrotreating catalyst C is vulcanized, it will -1 Under the condition of hydrogen-to-oil volume ratio of 1200, palm oil and dimethyl disulfide containing 0.3% by weight were subjected to hydrogenation reaction.

[0057] The hydrotreated reaction effluent enters the hot high-pressure separator, the temperature of the hot high-pressure separator is 200° C., and the separated liquid hydrocarbon contains 100 mg / kg of water and 200 mg / kg of sulfur.

[0058] 100mL of prepared hydroisomerization catalyst F is installed in the hydroisomerization reactor. After the hydroisomerization catalyst is vulcanized, the -1 Under the condition of hydrogen-to-oil volume ratio of 800, the liquid hydrocarbon undergoes hydroisomerization reaction, and the re...

Embodiment 2

[0060] In this embodiment, waste catering oil is used as the raw material of oil and fat, and the main properties of waste catering oil are shown in Table 2. figure 1 The process flow shown. 100mL hydrotreating catalyst C is installed in the hydrotreating reactor. After hydrotreating catalyst C is vulcanized, it will -1 Under the condition that the volume ratio of hydrogen to oil is 1000, the waste catering oil and the dimethyl disulfide containing 0.2% by weight are subjected to hydrogenation treatment reaction.

[0061] The hydrotreated reaction effluent enters the hot high-pressure separator, the temperature of the hot high-pressure separator is 200° C., and the separated liquid hydrocarbon contains 100 mg / kg of water and 150 mg / kg of sulfur.

[0062] 100mL of the prepared hydroisomerization catalyst F is installed in the hydroisomerization reactor. After the hydroisomerization catalyst is vulcanized, it will -1 Under the condition of hydrogen-to-oil volume ratio of 800, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com