Synthetic method of sheet-shape Co2P-carbon cloth composite material

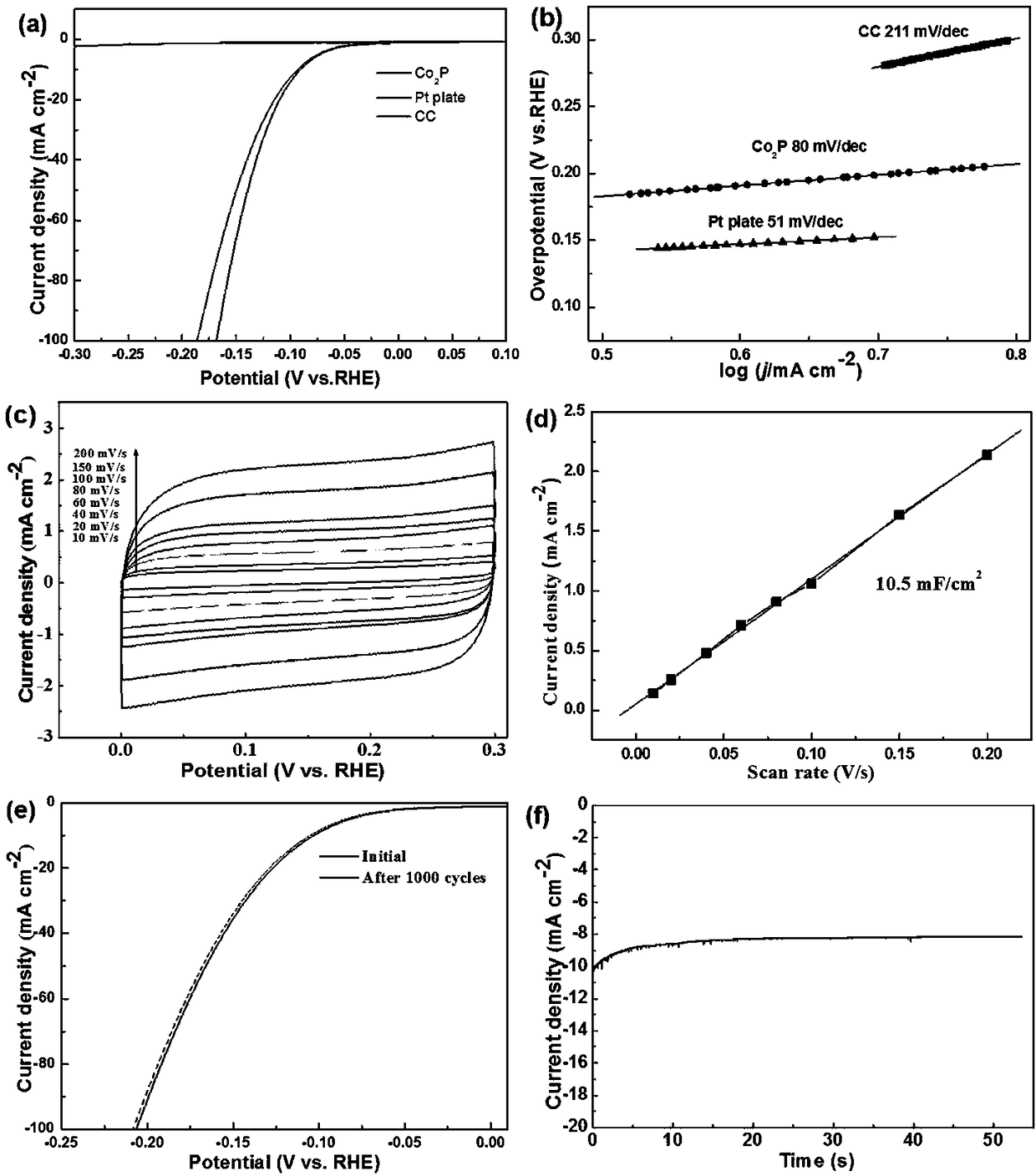

The technology of a composite material and a synthesis method is applied in the synthesis field of sheet-like Co2P-carbon cloth composite material, which can solve the problems of high overpotential, low electrochemical stability, low exchange current, etc., and achieve enhanced electrical conductivity and good durability. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

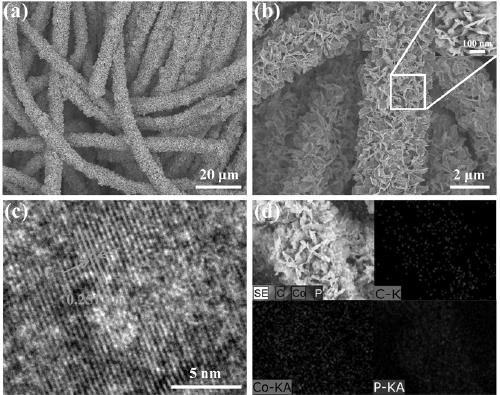

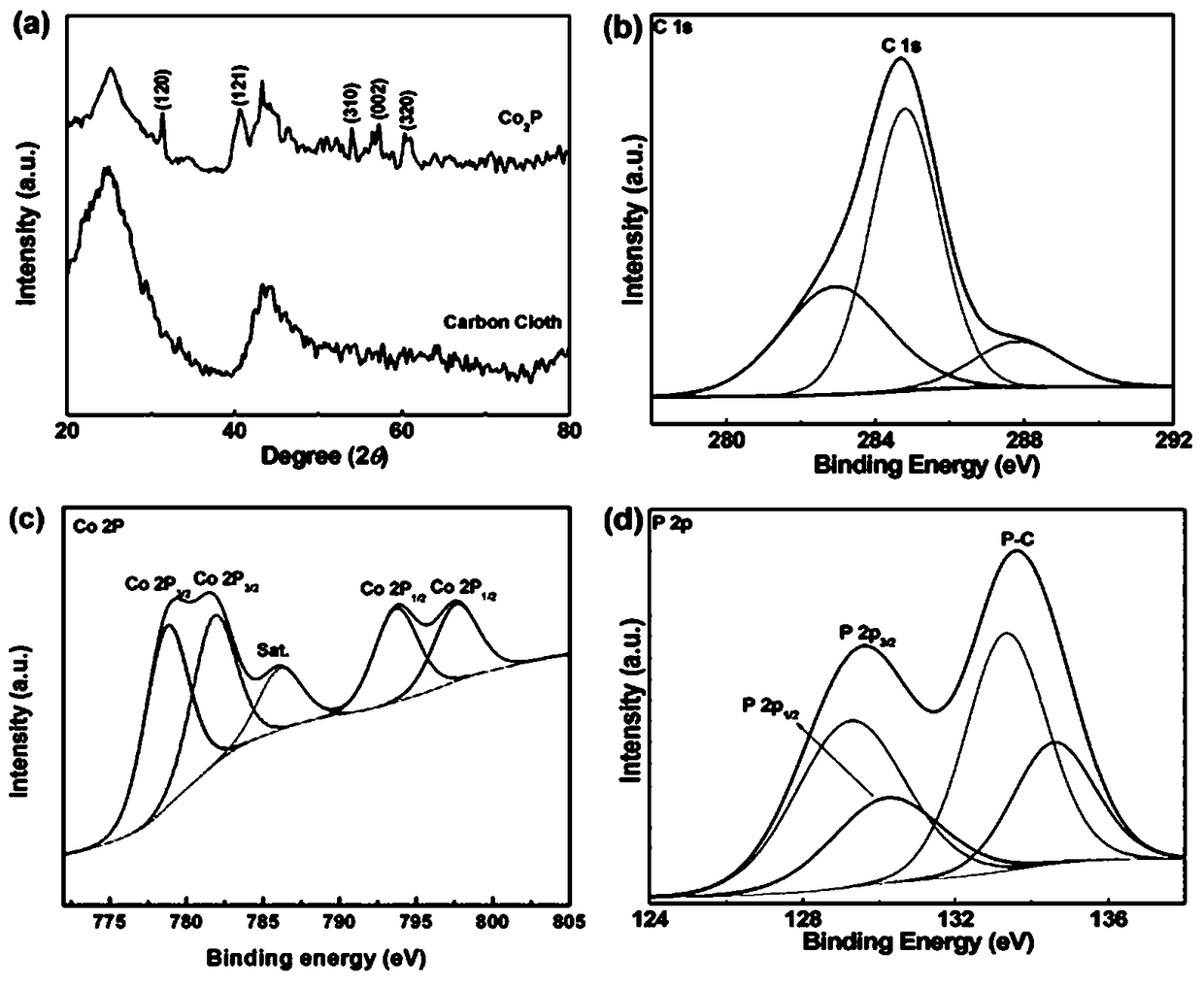

[0023] A flake Co 2 The synthetic method of P-carbon cloth composite material, comprises the following steps:

[0024] 1. Hydrothermal synthesis of Co(OH)(CO 3 ) 0.5 ·xH 2 O / CC compound: 1 mmol CoCl 2 and 3 mmol of urea were dissolved in 20 mL of deionized water, then the above solution was transferred to a polytetrafluoroethylene autoclave, and 0.5 mmol of CoCl was added 2 and 1.5mmol urea, put a piece of carbon cloth (2×2cm 2 ) were ultrasonically cleaned in methanol, ethanol and deionized water for 30 minutes, and then put into the above solution, and the autoclave was sealed and kept at 120°C for 12 hours; Washing in medium, and then vacuum drying at 60°C for 24 hours, the intermediate product Co(OH)(CO 3 ) 0.5 ·xH 2 O / CC;

[0025] 2. Phosphating process: carried out in a tube furnace, NaH 2 PO 2 and the intermediate product (according to the molar ratio of P and Co is 5:1) are respectively placed in two porcelain boats, which will contain NaH 2 PO 2 The porce...

Embodiment 2

[0027] A flake Co 2 The synthetic method of P-carbon cloth composite material, comprises the following steps:

[0028] 1. Hydrothermal synthesis of Co(OH)(CO 3 ) 0.5 ·xH 2 O / CC compound: 1 mmol CoCl 2 and 3 mmol of urea were dissolved in 20 mL of deionized water, then the above solution was transferred to a polytetrafluoroethylene autoclave, and 2 mmol of CoCl was added 2 and 6mmol urea, put a piece of carbon cloth (2×2cm 2 ) were ultrasonically cleaned in methanol, ethanol and deionized water for 30 minutes, and then put into the above solution, and the autoclave was sealed and kept at 120°C for 12 hours; Washing in medium, and then vacuum drying at 60°C for 24 hours, the intermediate product Co(OH)(CO 3 ) 0.5 ·xH 2 O / CC;

[0029]2. Phosphating process: carried out in a tube furnace, NaH 2 PO 2 and the intermediate product (according to the molar ratio of P and Co is 5:1) are respectively placed in two porcelain boats, which will contain NaH 2 PO 2 The porcelain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com