A kind of sulfur-doped hard carbon material, its preparation method and its potassium ion battery as negative electrode

A technology of sulfur doping and potassium ions, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of complex preparation methods and inability to industrialize production, and achieve uniform distribution of sulfur elements, low production costs, and excellent electrochemical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] (1) Pickling high-sulfur coal with a sulfur content of 4.27% in 1mol / L hydrochloric acid solution for 24 hours, then soaking in NaOH solution for 24 hours, wherein the mass ratio of NaOH solution solute to high-sulfur coal after pickling is 1:1 , to prepare a pre-product after freeze-drying;

[0069] (2) heat-treat the pre-product at a heating rate of 2°C / min to 800°C, and keep it warm for 2 hours to obtain a hard carbon material;

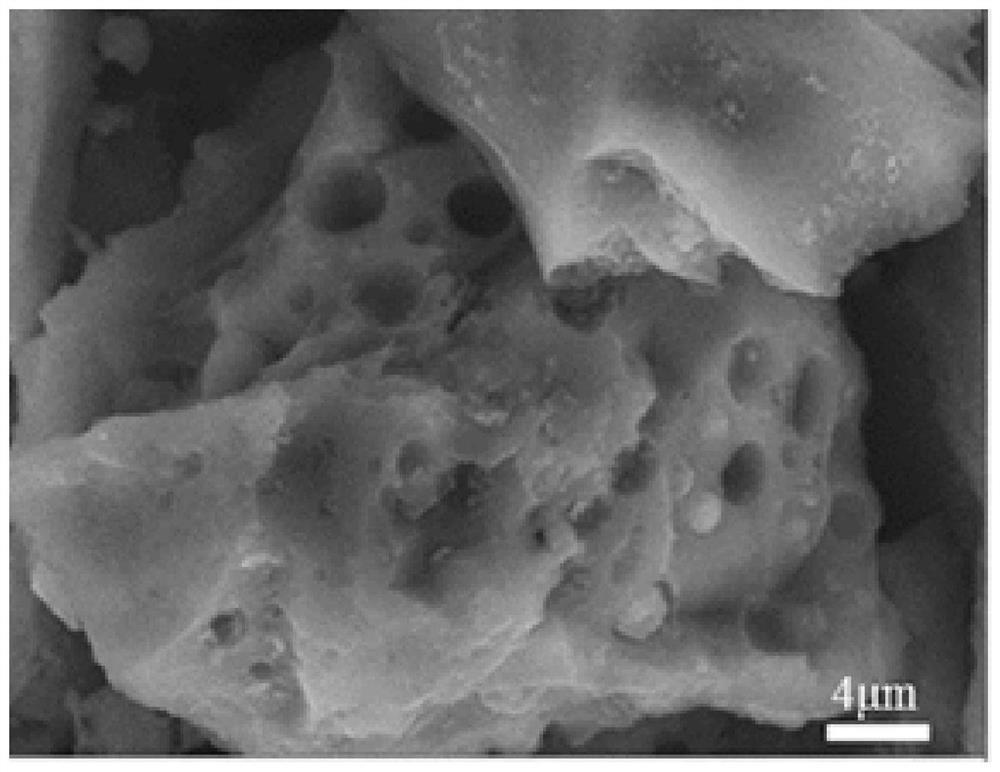

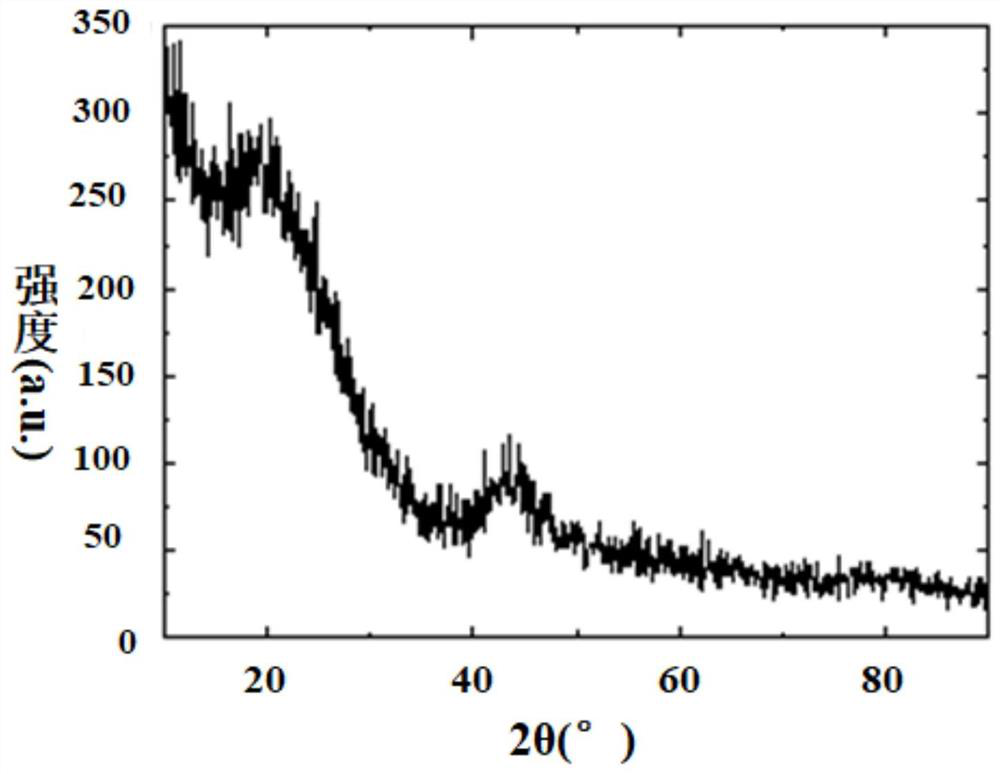

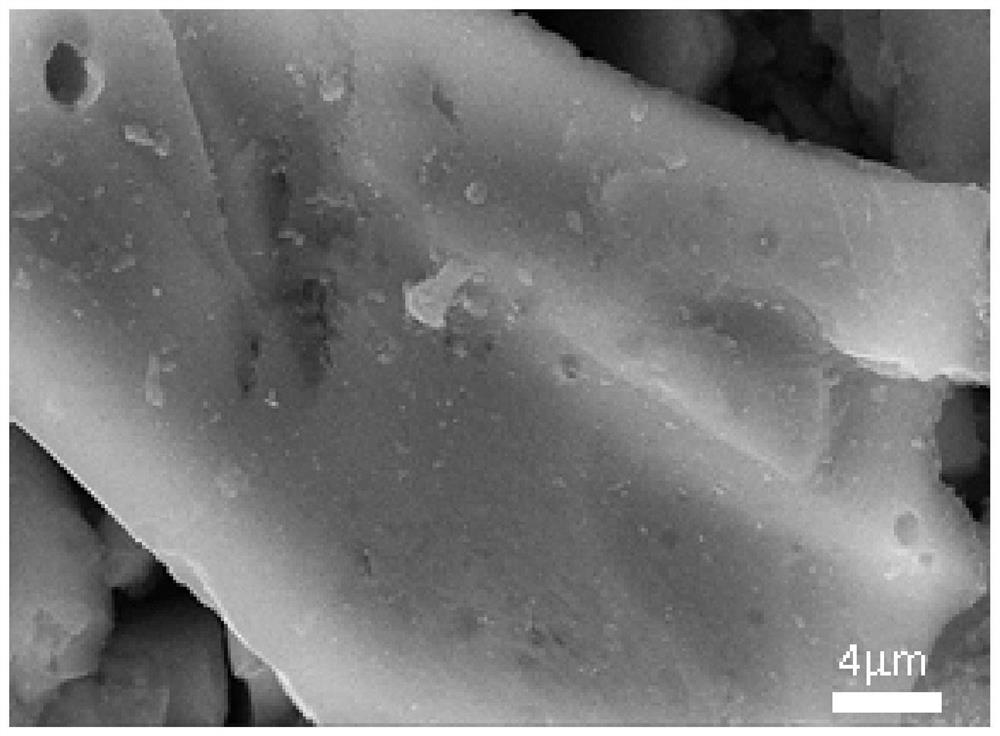

[0070] (3) Soak the hard carbon material in 2mol / L hydrochloric acid solution for 12h, wash with deionized water, filter and dry at 100°C to obtain a sulfur-doped hard carbon with a sulfur content of 3.75% and a pore size distribution of 0.5nm to 2μm Material, figure 1 It is the SEM image of the hard carbon material, as can be seen from the figure that the carbon is in a honeycomb structure, figure 2 It is the XRD spectrum of the hard carbon material, which shows that the hard carbon material is amorphous hard carbon.

Embodiment 2

[0072] The difference from Example 1 is that the sulfur content of the high-sulfur coal in step (1) is 3%, and a sulfur-doped hard carbon material with a sulfur content of 2.79% is obtained.

Embodiment 3

[0074] The difference from Example 1 is that the sulfur content of the high-sulfur coal in step (1) is 8%, and a sulfur-doped hard carbon material with a sulfur content of 7.49% is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com