High-energy-density lithium-ion battery electrolyte

A lithium-ion battery, high energy density technology, applied in the field of lithium-ion batteries, can solve the problems affecting the long-term development of power batteries, hidden dangers of lithium batteries, safety, and unsatisfactory long life, and achieve high anti-oxidation properties and compatibility Good performance and excellent self-extinguishing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

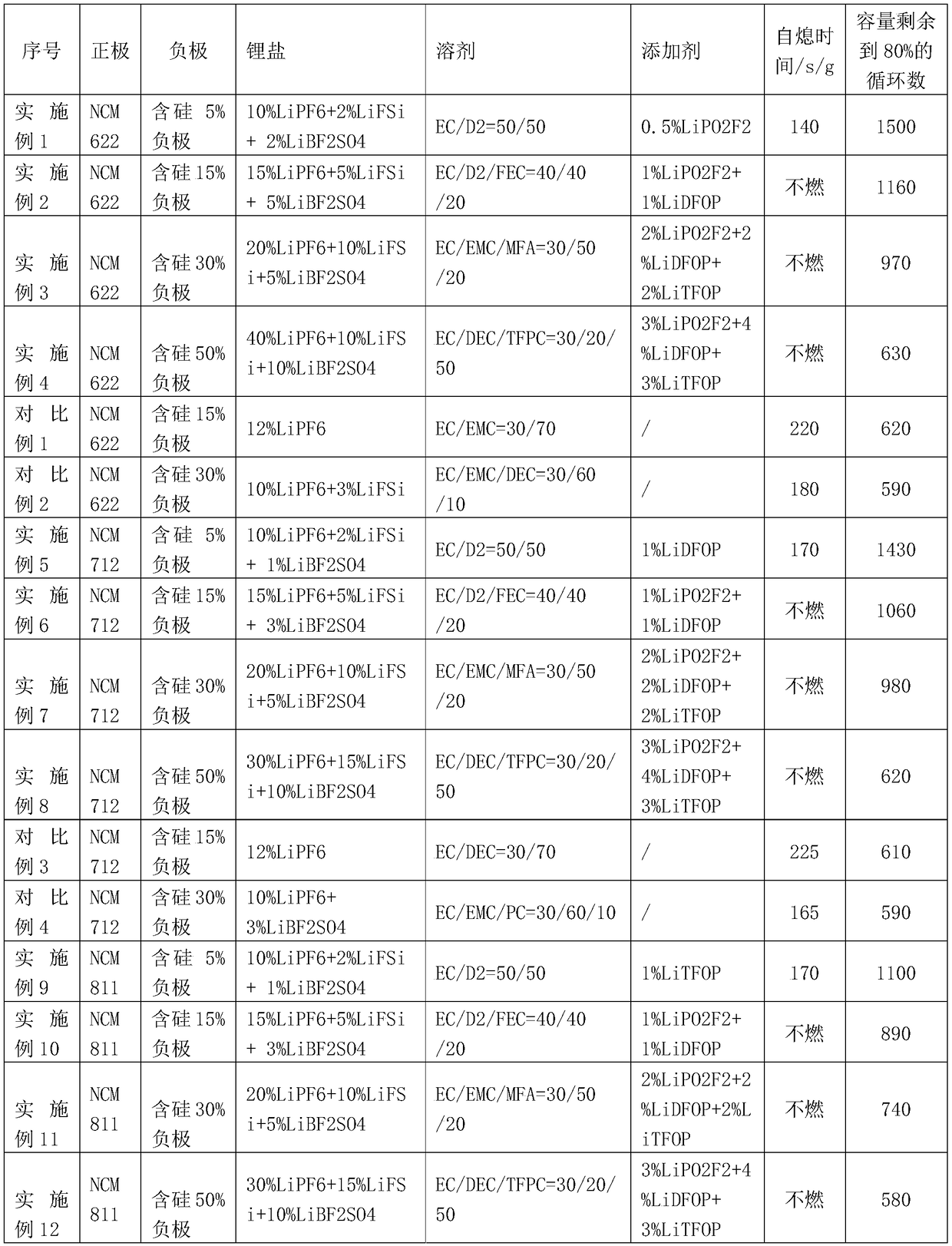

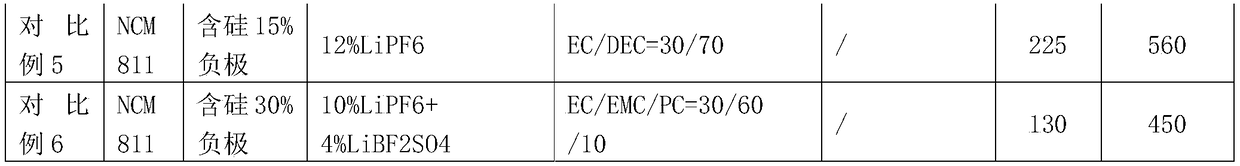

Examples

Embodiment 1

[0039] A high energy density lithium-ion battery electrolyte, the electrolyte is made of raw materials comprising the following weight percentages: LiPF 6 15%, LiFSi 3%, LiBF 2 SO 4 2%, non-aqueous organic solvent 79.5%, LiPO 2 f 2 0.5%; wherein, the non-aqueous organic solvent is ethylene carbonate and 1,1,2,2-tetrafluoroethyl-2,2,3,3-tetrafluoropropyl ether, and the mass ratio is 1:1.

[0040] The preparation method of the high-energy-density lithium-ion battery electrolyte includes the following steps: adding a lithium salt to a non-aqueous organic solvent, adding an additive after stirring evenly, and obtaining the high-energy-density lithium-ion battery electrolyte after stirring evenly .

[0041] The electrolyte is injected into a lithium-ion battery whose positive electrode is NCM622 and the negative electrode contains 5% silicon, and the battery is subjected to cycle performance testing after shelving, pre-charging, formation, and capacity separation in sequence....

Embodiment 2

[0043] A high energy density lithium-ion battery electrolyte, the electrolyte is made of raw materials comprising the following weight percentages: LiPF 6 15%, LiFSi 5%, LiBF 2 SO 4 5%, non-aqueous organic solvent 73%, LiPO 2 f 2 1%, LiDFOP 1%; Among them, non-aqueous organic solvents are ethylene carbonate, 1,1,2,2-tetrafluoroethyl-2,2,3,3-tetrafluoropropyl ether and fluoroethylene carbonate , the mass ratio is 2:2:1.

[0044] The preparation method of the high-energy-density lithium-ion battery electrolyte includes the following steps: adding a lithium salt to a non-aqueous organic solvent, adding an additive after stirring evenly, and obtaining the high-energy-density lithium-ion battery electrolyte after stirring evenly .

[0045] The electrolyte is injected into a lithium-ion battery whose positive electrode is NCM622 and the negative electrode contains 5% silicon, and the battery is subjected to cycle performance testing after shelving, pre-charging, formation, a...

Embodiment 3

[0047] A high energy density lithium-ion battery electrolyte, the electrolyte is made of raw materials comprising the following weight percentages: LiPF 6 20%, LiFSi 10%, LiBF 2SO 4 5%, non-aqueous organic solvent 59%, LiPO 2 f 2 2%, LiDFOP 2%, LiTFOP 2%; wherein, the non-aqueous organic solvent is ethylene carbonate, ethyl methyl carbonate and methyl difluoroacetate, and the mass ratio is 3:5:2.

[0048] The preparation method of the high-energy-density lithium-ion battery electrolyte includes the following steps: adding a lithium salt to a non-aqueous organic solvent, adding an additive after stirring evenly, and obtaining the high-energy-density lithium-ion battery electrolyte after stirring evenly .

[0049] The electrolyte is injected into a lithium-ion battery whose positive electrode is NCM622 and the negative electrode contains 30% silicon, and the battery is subjected to cycle performance testing after shelving, pre-charging, formation, and capacity separation i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com