A carbon fiber pulse power switch

A technology of pulse power switch and carbon fiber, which is applied in the direction of electrical components, spark gaps, circuits, etc., can solve the problems of high voltage resistance, large jitter, and detachment of self-breakdown switches, so as to reduce delay and delay jitter , Reduce the limit of working life, improve the effect of high temperature ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

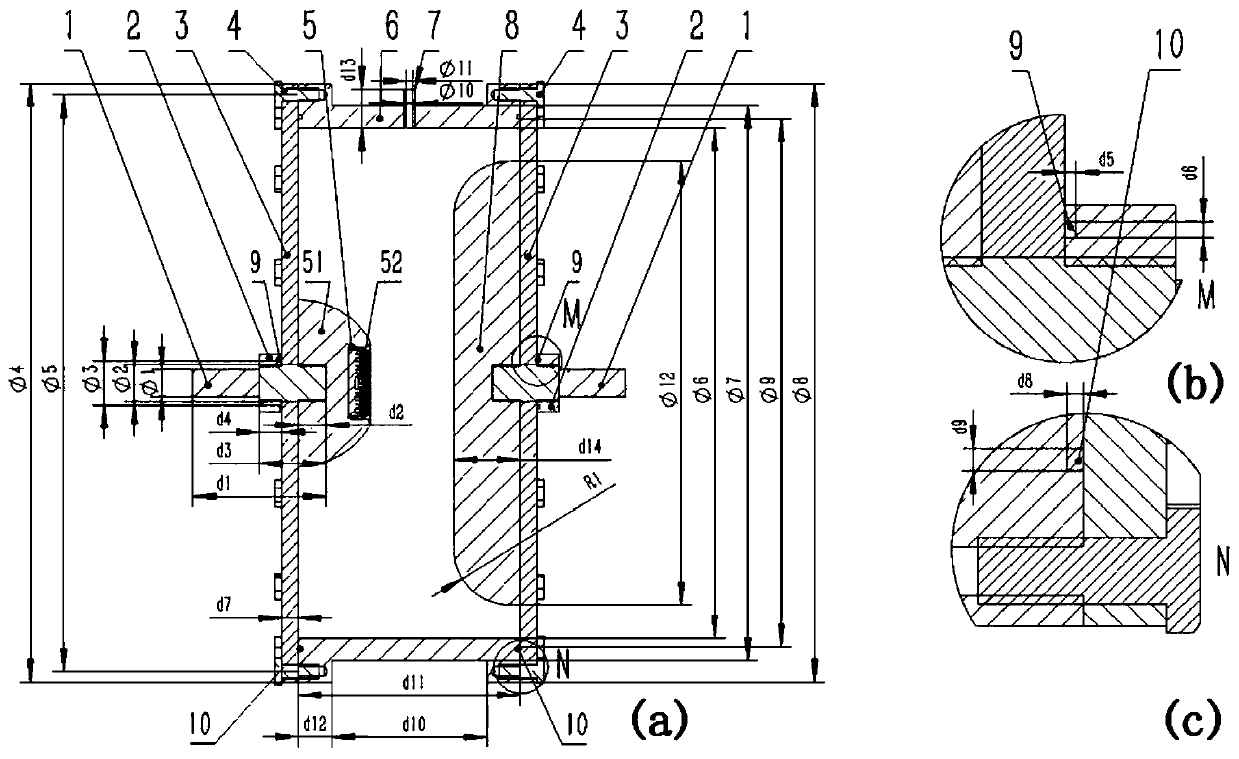

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

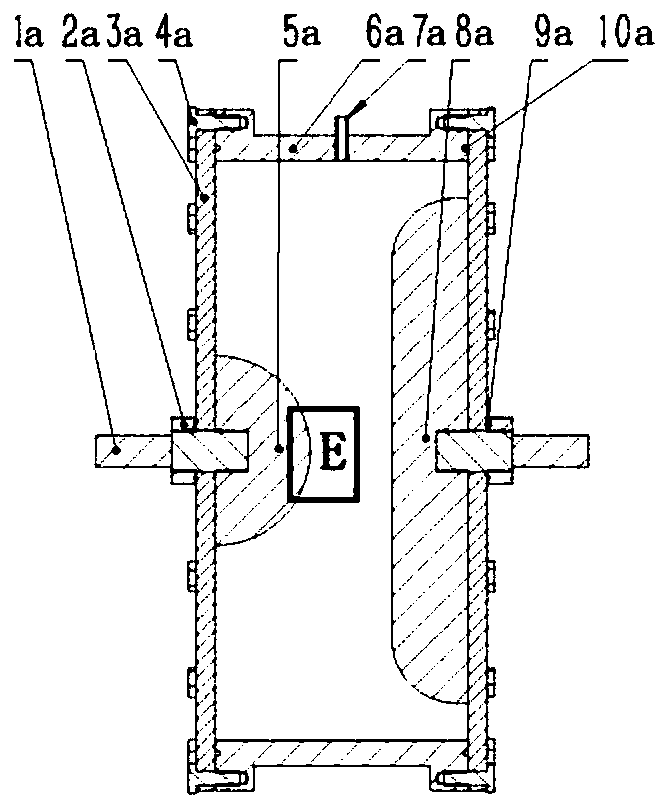

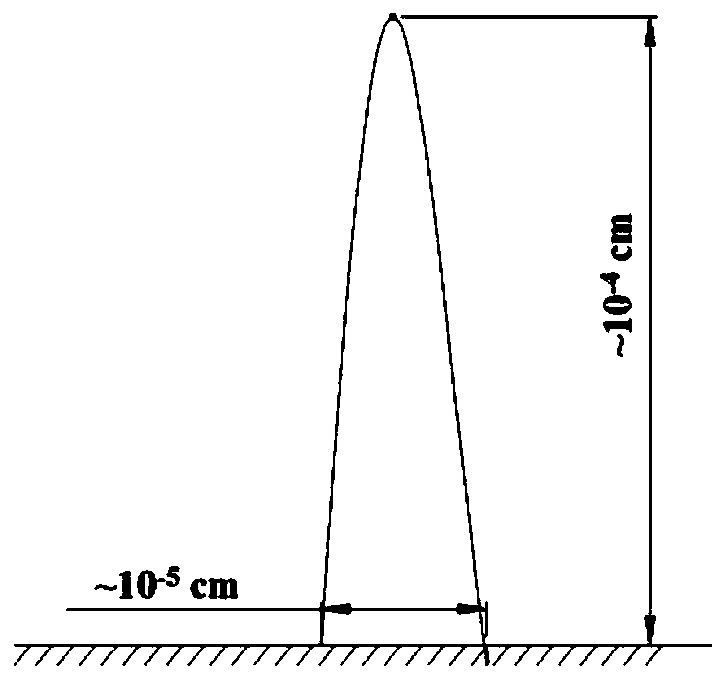

[0028] Such as Figure 3-5 As shown, the carbon fiber pulse power switch of the present invention is rotationally symmetrical around the central axis, including a metal connecting rod 1, a fixing nut 2, a dielectric sealing plate 3, a screw rod 4, a cathode electrode 5, a dielectric outer cylinder 6, an air nozzle 7, and an anode electrode 8 , small sealing ring 9 and large sealing ring 10, wherein the cathode electrode 5 includes a cathode electrode base 51 and a carbon fiber disc 52, and the carbon fiber disc 52 includes a metal perforated chassis 521, several carbon fiber bundles 522 and a fixed pressure plate 523.

[0029] For the convenience of description, it is stipulated below that: the end where the cathode electrode 5 is located is the left end, and the end where the anode electrode 8 is located is the right end. The structure and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com