Method and device for preparing sorbitol through continuous hydrogenation of glucose

A technology of sorbitol and glucose, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve problems such as hydrogen loss, achieve low unit consumption, good effect, and stable system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

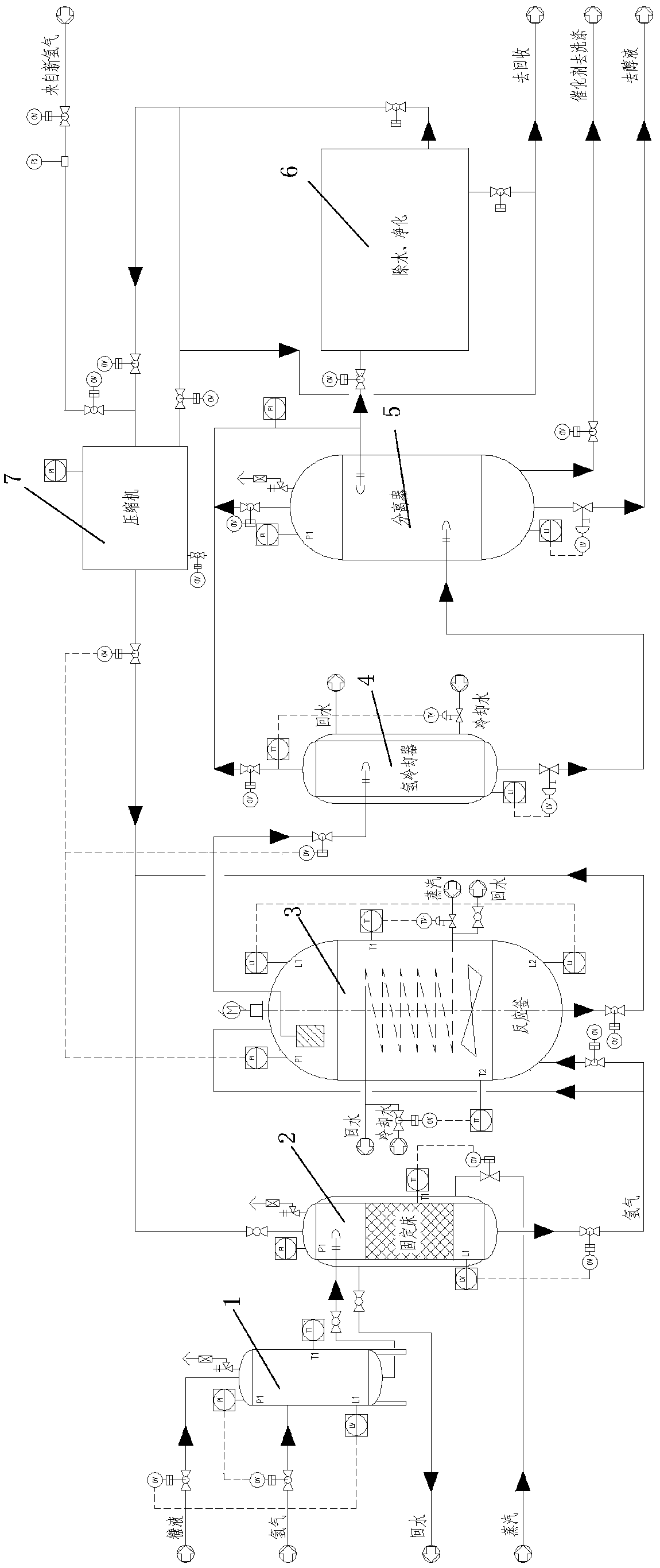

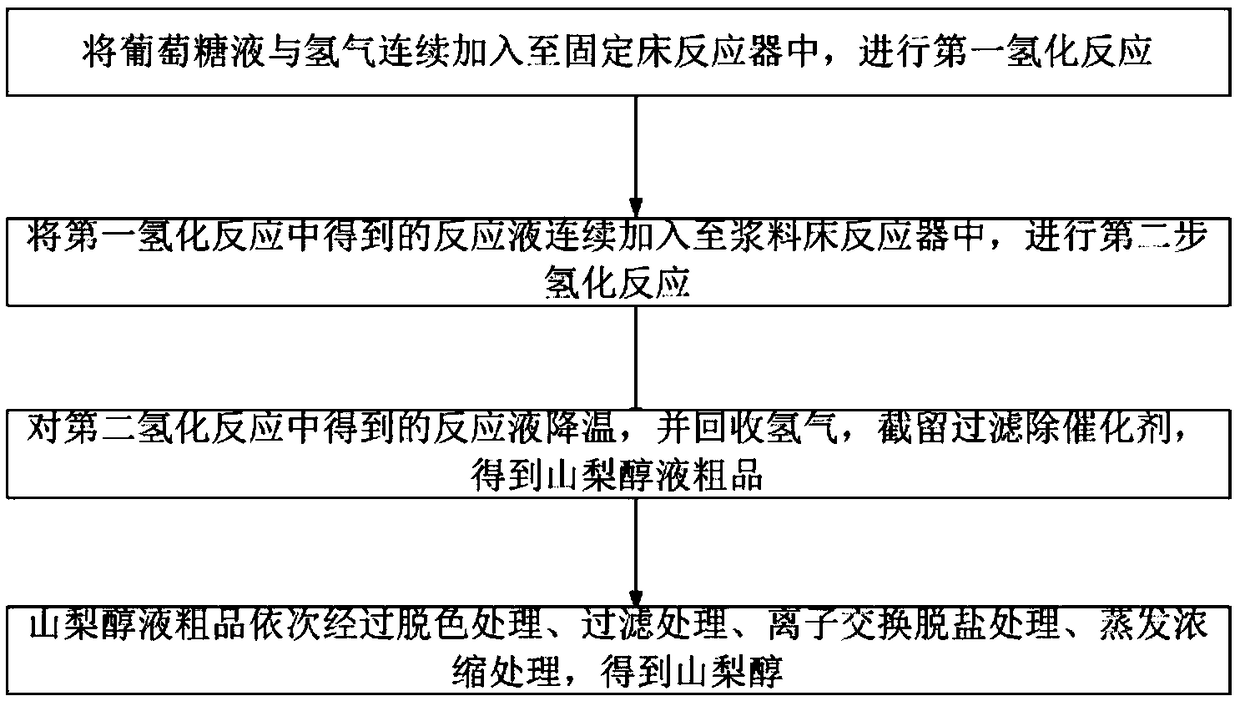

Method used

Image

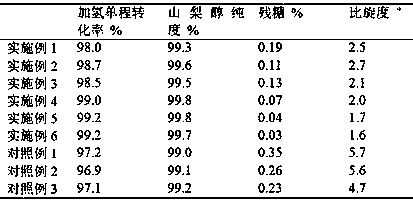

Examples

Embodiment 1

[0079] Step 1, prepare 80°C glucose solution with 40wt% concentration (containing about 100ppm Na+ and 220ppm Cl - impurities), and adjust the pH to 6-7 with HCl;

[0080] In the second step, the glucose solution and hydrogen are added to the fixed bed reactor to carry out the first hydrogenation reaction; RaneyNi catalyst is used, the reactor pressure is 10.5MPa, the temperature is controlled at 90°C, and the material residence time is 1 hour;

[0081] In the third step, the reaction solution obtained in the first hydrogenation reaction is added to the slurry bed reactor to carry out the second hydrogenation reaction; an activated carbon-supported Ru catalyst is used; the reactor pressure is 11.0MPa, and the temperature is controlled at 100°C. Material residence time 1 hour

[0082] In the 4th step, the temperature of the reaction liquid obtained in the second hydrogenation reaction is lowered, and the hydrogen is recovered, and after the catalyst is removed, the crude produ...

Embodiment 2

[0085] Step 1, prepare 90°C glucose solution with 50wt% concentration (containing about 100ppm Na+ and 220ppm Cl - impurities), and adjust the pH to 6-7 with HCl;

[0086] In the second step, glucose liquid and hydrogen are added to the fixed bed reactor to carry out the first hydrogenation reaction; RaneyNi catalyst is used, the reactor pressure is 12.5MPa, the temperature is controlled at 130°C, and the material residence time is 3 hours;

[0087] In the third step, the reaction liquid obtained in the first hydrogenation reaction is added to the slurry bed reactor to carry out the second hydrogenation reaction; an activated carbon-supported Ru catalyst is used; the reactor pressure is 13.5MPa, and the temperature is controlled at 140°C. Material residence time 1 to 3 hours

[0088]In the 4th step, the temperature of the reaction liquid obtained in the second hydrogenation reaction is lowered, and the hydrogen is recovered, and after the catalyst is removed, the crude produc...

Embodiment 3

[0091] Step 1, prepare 85°C glucose solution with 45wt% concentration (containing about 100ppm Na+ and 220ppm Cl - impurities), and adjust the pH to 6-7 with HCl;

[0092] In the second step, glucose liquid and hydrogen are added to the fixed-bed reactor to carry out the first hydrogenation reaction; RaneyNi catalyst is used, the reactor pressure is 11.5MPa, the temperature is controlled at 120°C, and the material residence time is 2 hours;

[0093] In the third step, the reaction solution obtained in the first hydrogenation reaction is added to the slurry bed reactor to carry out the second hydrogenation reaction; the Ru catalyst supported by activated carbon is used; the reactor pressure is 12.0MPa, and the temperature is controlled at 125°C. Material residence time 2 hours

[0094] In the 4th step, the temperature of the reaction liquid obtained in the second hydrogenation reaction is lowered, and the hydrogen is recovered, and after the catalyst is removed, the crude prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com