Preparation method of ti-al-c system max phase coating on titanium or titanium alloy surface

A ti-al-c, titanium alloy technology, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of mismatch between coating and substrate performance, coating cracking or peeling damage, etc. Achieve the effect of avoiding coating cracking or peeling damage, reducing the interference of impurity elements, and solving performance mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

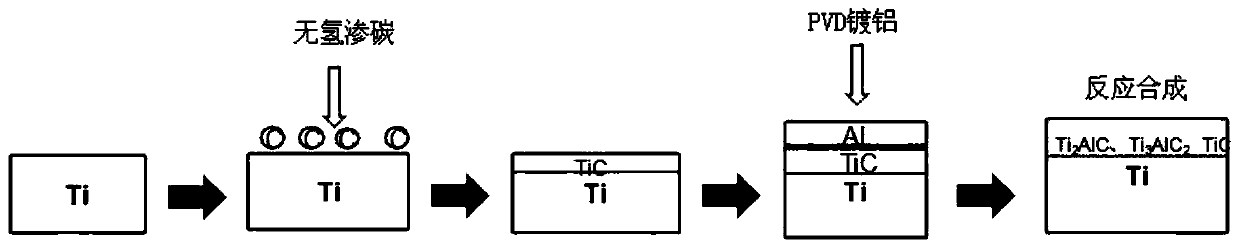

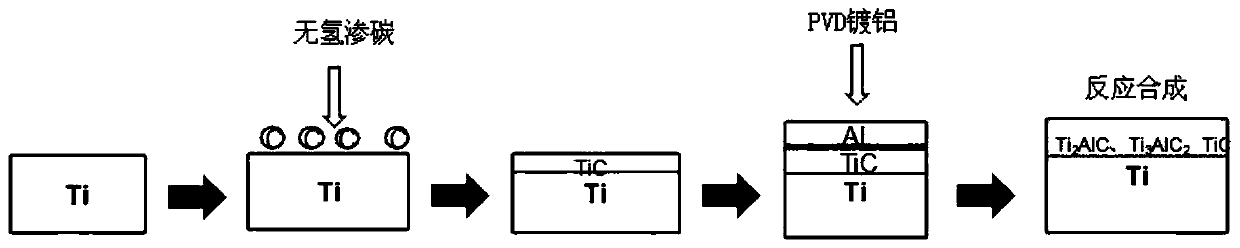

[0025] Such as figure 1 Shown, the preparation method of the present embodiment comprises the following steps:

[0026]Step 1, using a metal cleaning agent to degrease and clean the surface of the TA2 titanium alloy block;

[0027] Step 2. Place the TA2 titanium alloy block after surface degreasing and cleaning in step 1 in a hydrogen-free carburizing furnace for hydrogen-free carburizing treatment, so that the surface of the titanium or titanium alloy after surface degreasing and cleaning forms a TiC layer ; The thickness of the TiC layer is 50 μm;

[0028] Step 3, cleaning the surface of the TA2 titanium alloy block after the hydrogen-free carburizing treatment in step 2, then placing it in a vacuum physical vapor deposition device for vacuum physical vapor deposition, and coating the TiC layer on the surface of the TA2 titanium alloy block Al layer, forming an Al\TiC coating; the thickness of the Al layer is 10 μm;

[0029] Step 4. Place the TA2 titanium alloy block afte...

Embodiment 2

[0031] Such as figure 1 Shown, the preparation method of the present embodiment comprises the following steps:

[0032] Step 1, using a metal cleaning agent to degrease and clean the surface of the TC4 titanium alloy block;

[0033] Step 2. Place the TC4 titanium alloy block after surface degreasing and cleaning in step 1 in a hydrogen-free carburizing furnace for hydrogen-free carburizing treatment, so that a TiC layer is formed on the surface of the titanium or titanium alloy after surface degreasing and cleaning ; The thickness of the TiC layer is 100 μm;

[0034] Step 3, cleaning the surface of the TC4 titanium alloy block after the hydrogen-free carburizing treatment in step 2, then placing it in a vacuum physical vapor deposition device for vacuum physical vapor deposition, and coating the TiC layer on the surface of the TC4 titanium alloy block Al layer, forming an Al\TiC coating; the thickness of the Al layer is 20 μm;

[0035] Step 4. Place the TC4 titanium alloy b...

Embodiment 3

[0037] Such as figure 1 Shown, the preparation method of the present embodiment comprises the following steps:

[0038] Step 1, using a metal cleaning agent to degrease and clean the surface of the TC6 titanium alloy block;

[0039] Step 2. Place the TC6 titanium alloy block after surface degreasing and cleaning in step 1 in a hydrogen-free carburizing furnace for hydrogen-free carburizing treatment, so that a TiC layer is formed on the surface of the titanium or titanium alloy after surface degreasing and cleaning ; The thickness of the TiC layer is 150 μm;

[0040] Step 3, cleaning the surface of the TC6 titanium alloy block after the hydrogen-free carburizing treatment in step 2, then placing it in a vacuum physical vapor deposition device for vacuum physical vapor deposition, and coating the TiC layer on the surface of the TC6 titanium alloy block Al layer, forming an Al\TiC coating; the thickness of the Al layer is 30 μm;

[0041] Step 4. Place the TC6 titanium alloy b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com