Method for representing resin on wetting performance of glass fiber

A technology of glass fiber and resin, applied in the field of wettability testing, to achieve the effects of convenient development and screening, environmental friendliness, and simple testing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

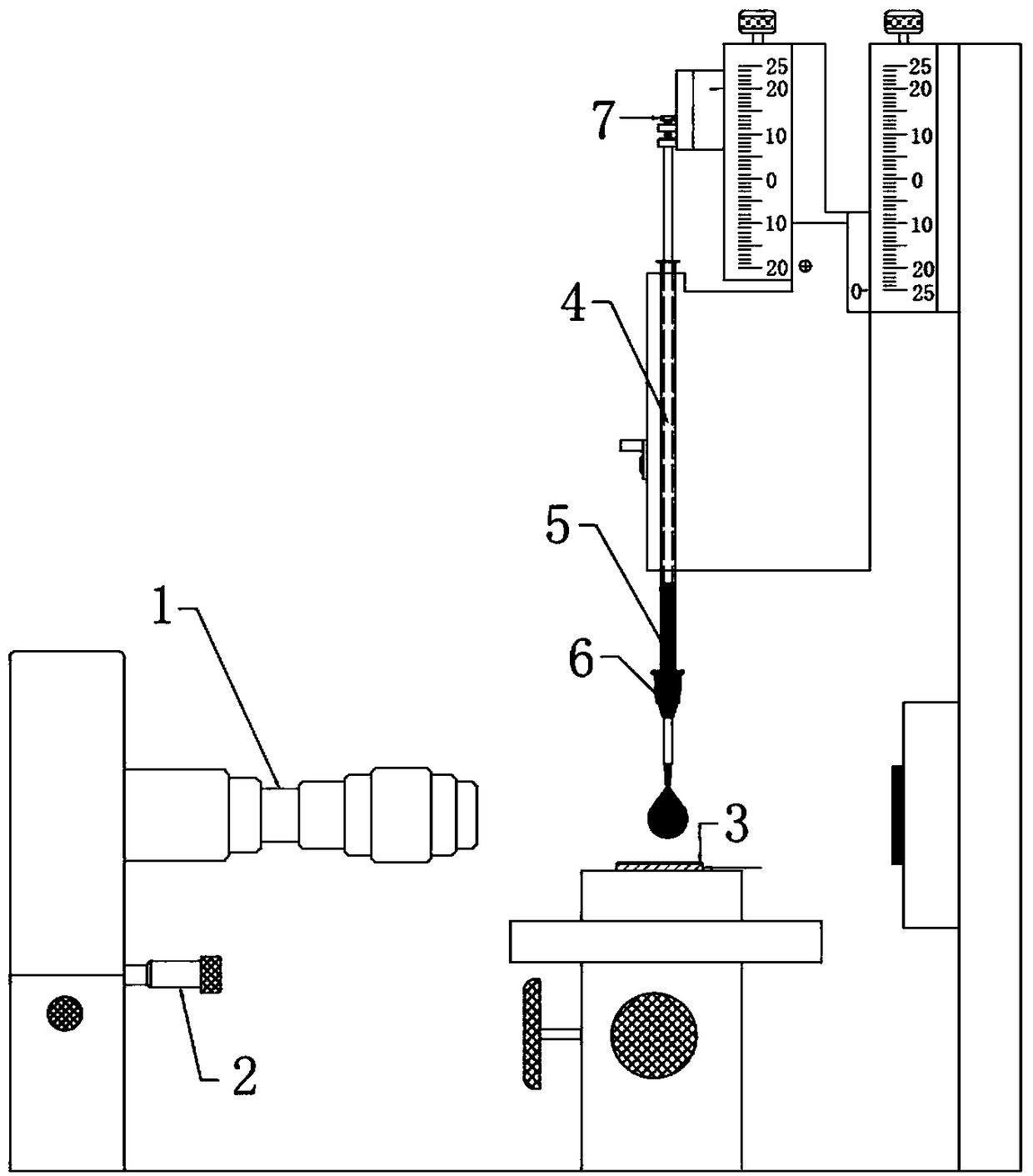

Method used

Image

Examples

Embodiment 1

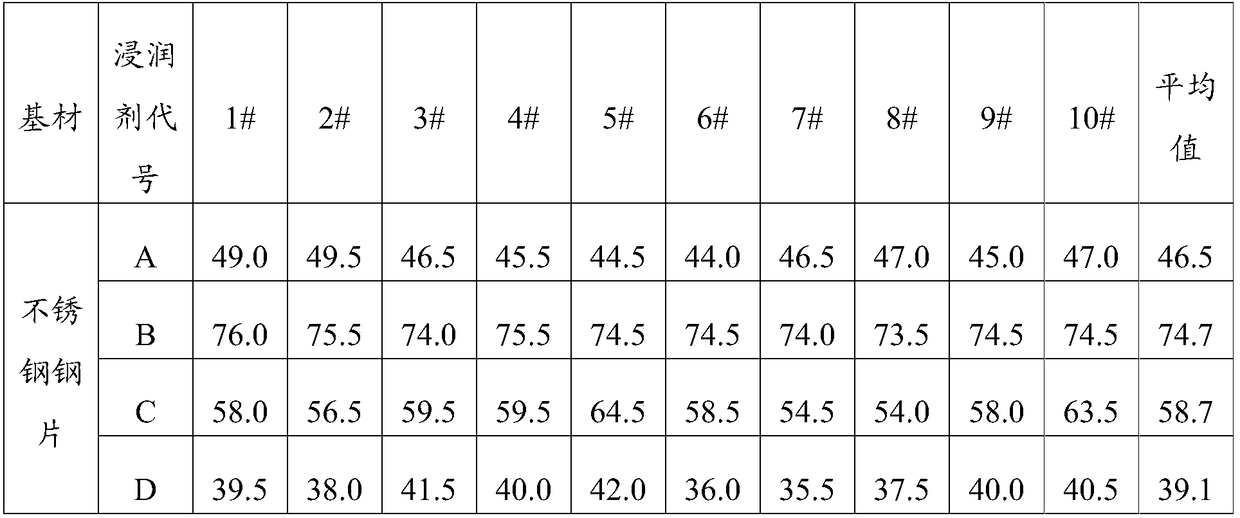

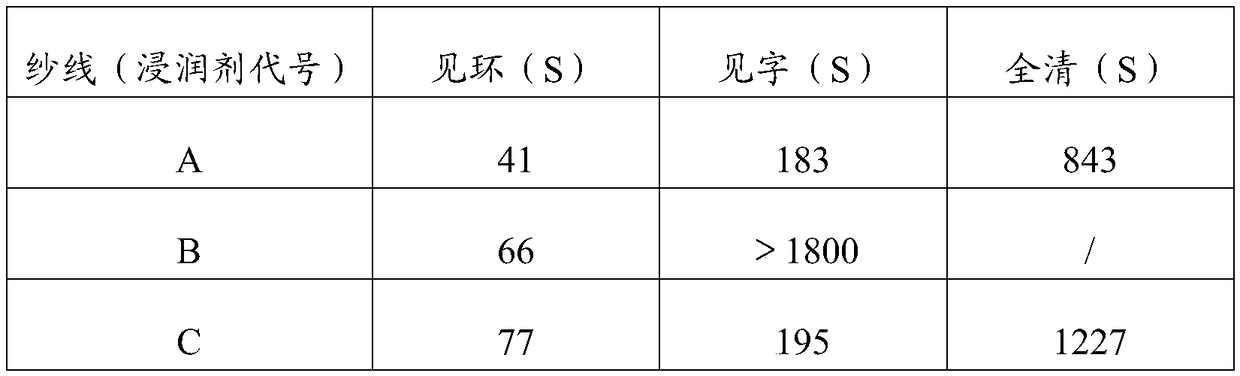

[0075] Select the direct yarn sizing agent as the solid phase and the epoxy resin solution as the liquid phase to test the contact angle, which specifically includes the following steps:

[0076] 1S: Use a wet film applicator to coat the direct yarn sizing agent on the solid sheet of the contact angle measuring instrument. The solid sheet is a smooth stainless steel sheet with a length of 100mm, a width of 25mm, and a thickness of 2mm; the direct yarn sizing agent The solid content is 10%; the solid sheet coated with the direct yarn sizing agent is sent into a drying oven for drying to obtain the sizing agent sheet;

[0077] The temperature settings in the drying oven are specifically:

[0078] 1) Raise the temperature from room temperature to 100°C and keep it for 180 minutes; the heating time is 360 minutes;

[0079] 2) Continue to heat up to 122°C and keep for 180 minutes; the heating time is 180 minutes;

[0080] 2S: Select the epoxy resin with the brand name 2500-1A pro...

Embodiment 2

[0086] Select the spun yarn sizing agent as the solid phase and the unsaturated resin solution as the liquid phase to test the contact angle, which specifically includes the following steps:

[0087] 1S: Use a wet film applicator to coat the ply yarn sizing agent on the solid sheet of the contact angle measuring instrument. The solid sheet is a smooth stainless steel sheet with a length of 60mm, a width of 20mm, and a thickness of 3mm; the solid content of the sizing agent 8%; the solid sheet coated with the sizing agent for the plied yarn is sent into a drying oven for drying to obtain a sheet of the sizing agent;

[0088] The temperature settings in the drying oven are specifically:

[0089] 1) Raise the temperature from room temperature to 100°C and keep it for 120 minutes; the heating time is 360°C;

[0090] 2) Continue to raise the temperature to 132°C and keep it for 180 minutes; the heating time is 180 minutes.

[0091] 2S: Select the unsaturated resin with the brand ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com