Hybrid capacitor and manufacturing method thereof

一种混合电容器、电容器的技术,应用在混合/双电层电容器制造、混合电容器、混合电容器电极等方向,能够解决充放电循环可靠性问题、难极速充放电等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

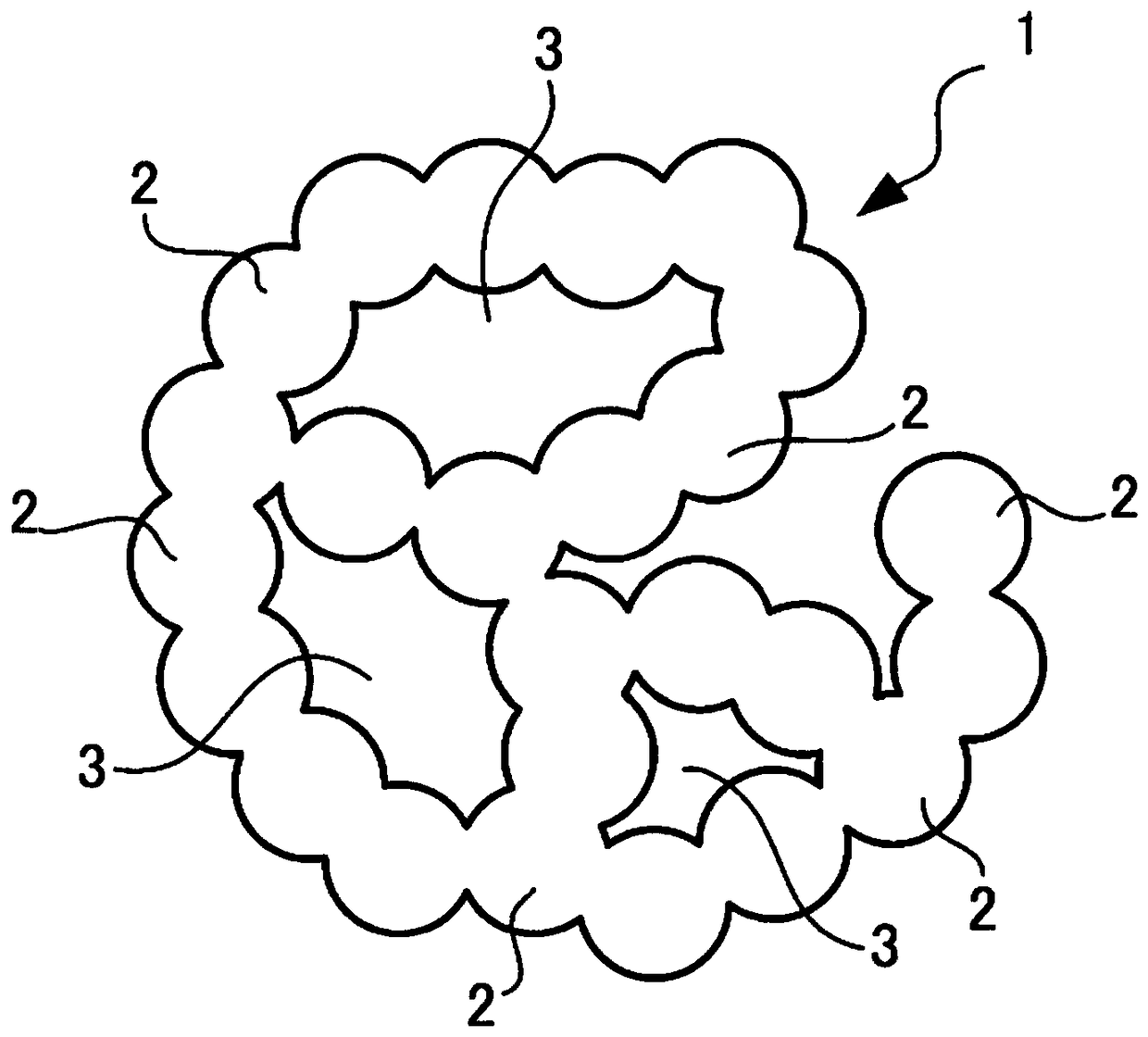

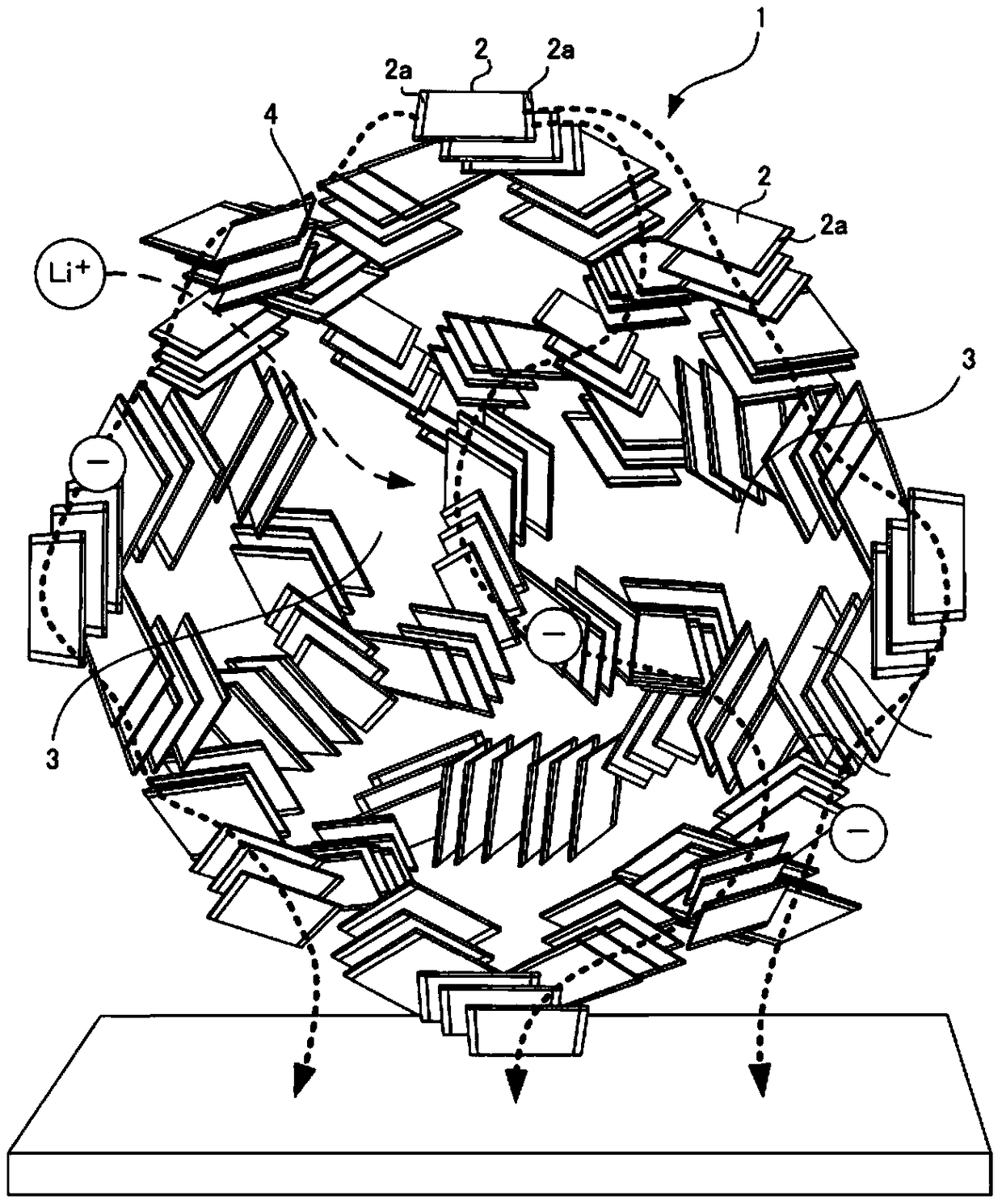

[0102] (4-1. Negative electrode active material)

[0103] The following three steps are performed to generate a three-dimensional network structure negative electrode active material. First, 20 g of carbon nanofibers and 245 g of titanium tetraisopropoxide were added to 1300 g of isopropanol. The weight ratio of titanium alkoxide to carbon nanofibers is selected so that the weight ratio of lithium titanate to carbon nanofibers after the first step is about 8:2.

[0104] The obtained liquid is introduced into the inner cylinder of the reactor to apply 35000kgms to the liquid -2 The centrifugal force makes the inner cylinder rotate for 300 seconds, so that the carbon nanofibers are highly dispersed in the liquid. The reactor includes a concentric cylinder of the outer cylinder and the inner cylinder, and a through hole is provided on the side of the inner cylinder, and the outer cylinder The opening is provided with a baffle.

[0105] Furthermore, 165 g of acetic acid and 50 ...

example 1

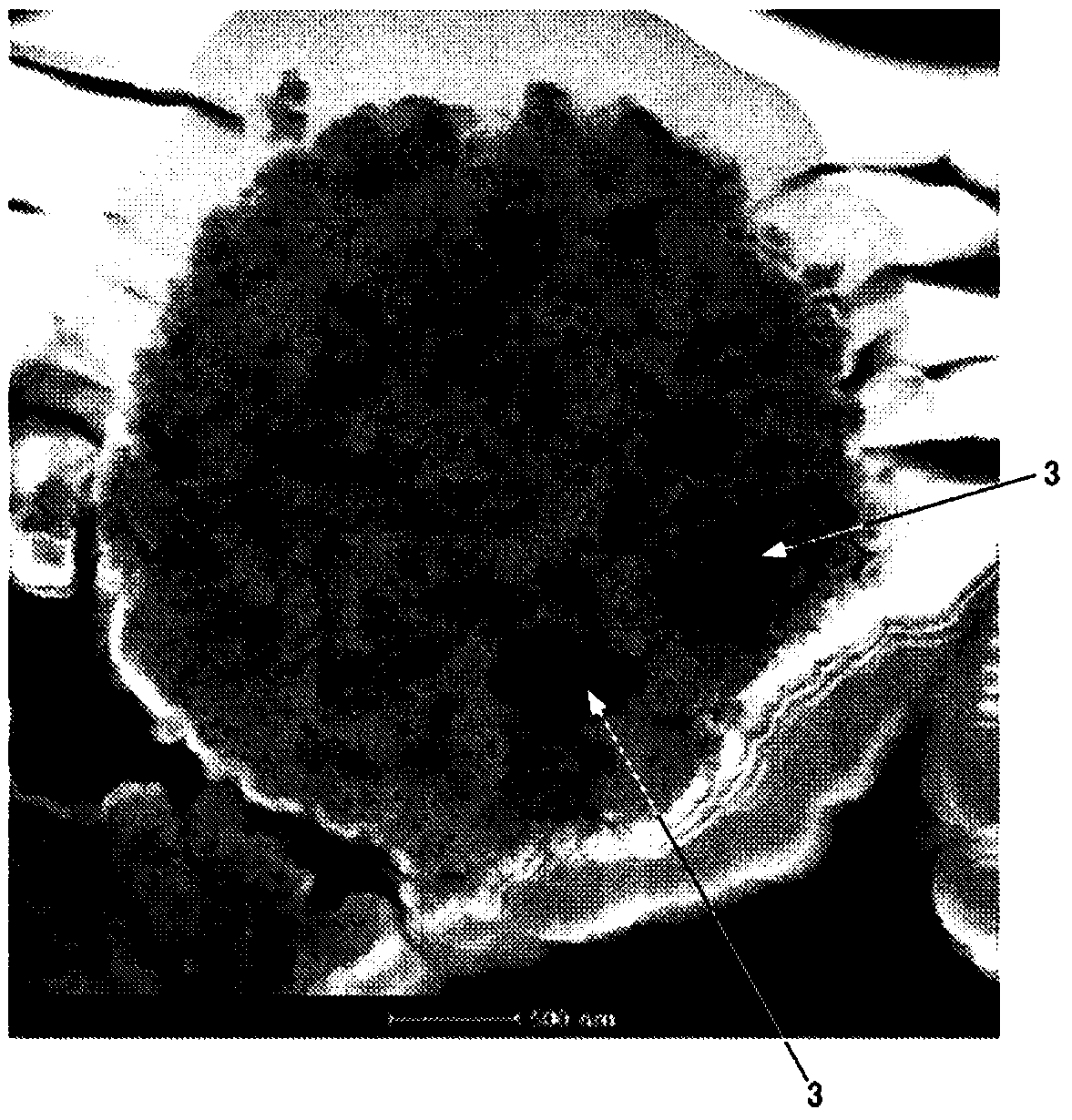

[0111] Compared with Example 1, the negative electrode active material is different. The negative electrode active material 2 a of Comparative Example 1 is lithium titanate particles produced without using carbon. That is, to an aqueous solution of 38 g of lithium hydroxide and 800 g of water, 87 g of titanium oxide (TiO 2 ), stirring to obtain a solution. The solution was introduced into a spray drying apparatus and spray-dried to obtain a dry product. The obtained dried granules were heat-treated at a temperature of 700° C. for 3 hours in the air to obtain lithium titanate particles.

[0112] With regard to the lithium titanate particles, since no carbon is present in the production step, there are no voids obtained by removing carbon, and thus do not have a three-dimensional network structure. The configuration other than the hybrid capacitor such as positive and negative current collectors, separators, and electrolyte solutions is the same as that of Example 1.

[0113...

Embodiment 1-1

[0126] In Example 1, 100 g of the product obtained by heat treatment in a nitrogen atmosphere was subjected to heat treatment in an oxygen atmosphere at 500° C. for 6 hours, while in Example 1-1, at 350° C. A negative electrode active material was obtained in the same manner as in Example 1 except that 100 g of the product obtained by the heat treatment in a nitrogen atmosphere was heat-treated for 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com