Ferrite particles, resin composition and electromagnetic shielding material

A technology of resin composition and shielding material, applied in shielding materials, magnetic materials, iron compounds, etc., can solve the problem of inability to shield electromagnetic waves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] As an example of the preparation method of ferrite raw material (granulated material), Fe raw material and Mn raw material, and if necessary, Mg raw material and Sr raw material are weighed to form the desired ferrite composition, and water is added to pulverize to prepare slurry material. The prepared slurry is granulated with a spray dryer, and then classified to prepare granules with a specified particle size. In consideration of the particle diameter of the obtained ferrite particles, the particle diameter of the granulated material is preferably 500 to 10000 nm. Furthermore, as another example, ferrite raw materials having a prepared composition are mixed and dry-milled, and after pulverizing and dispersing each raw material, the mixture is granulated and classified by a granulator to prepare granules with a predetermined particle diameter.

[0061] The thus-prepared granules were subjected to thermal spraying in the air to ferrite them. Thermal injection can use...

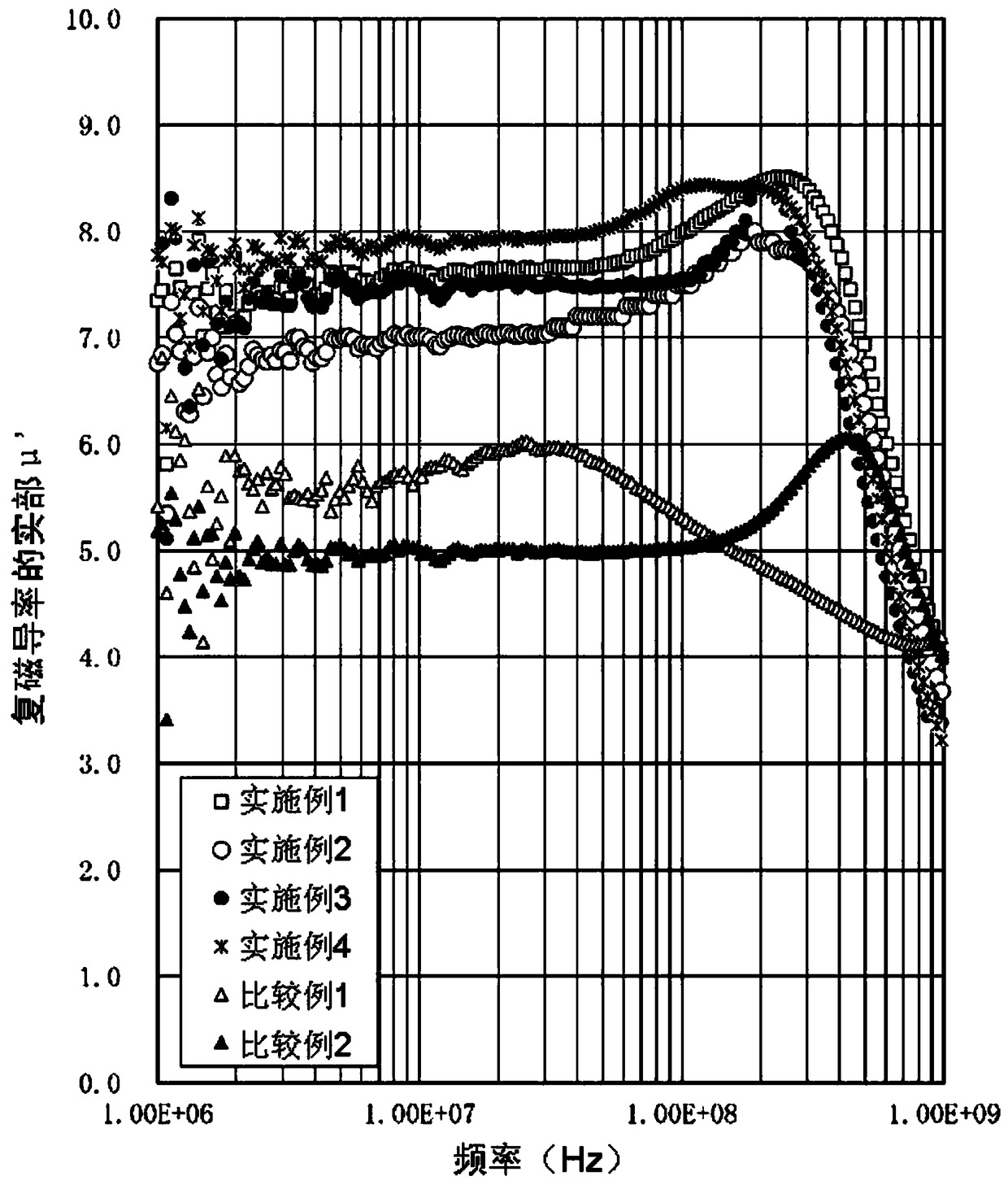

Embodiment 1

[0076] Measure and mix iron oxide (Fe 2 o 3 ) and manganese oxide (MnO). Water was added to the obtained mixture, and it was pulverized to prepare a slurry having a solid content of 50% by weight. The obtained slurry was granulated and classified with a spray dryer to prepare a granulated product with an average particle diameter of 5000 nm.

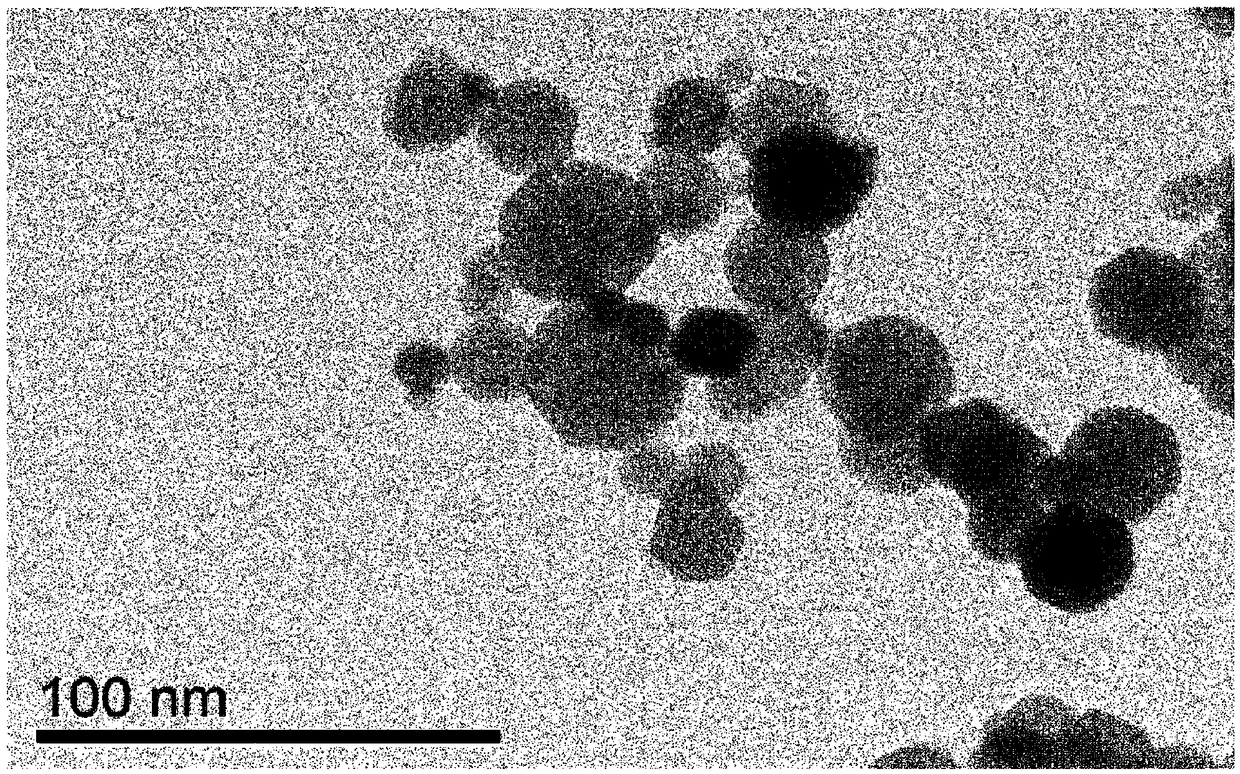

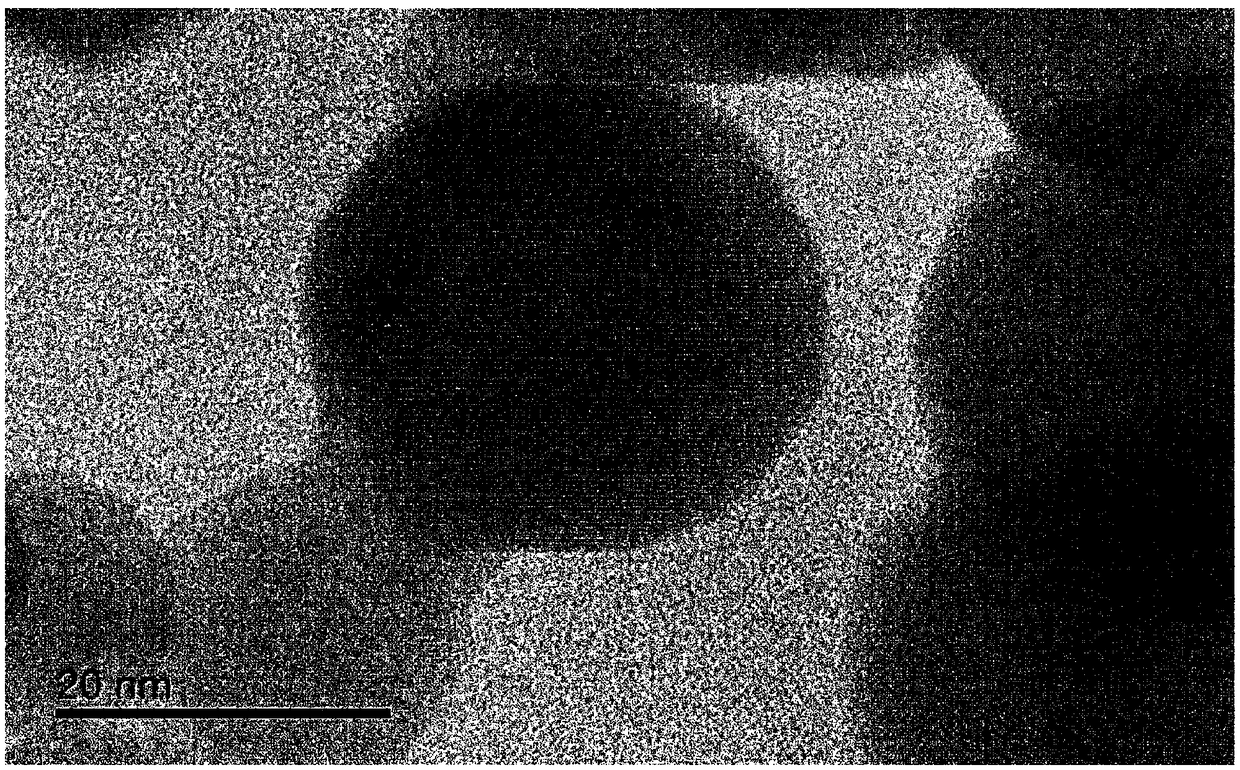

[0077] Subsequently, the obtained granules were dissolved in propane:oxygen=10Nm 3 / hr:35Nm 3 / hr in a combustible gas flame at a flow rate of about 40m / sec to perform ferriteization by thermal spraying, and then, carry on the airflow formed by the air supply and transport it to perform quenching in the atmosphere. At this time, since thermal spraying is performed while the granulated material is continuously flowing, the particles after thermal spraying and quenching are not mutually bonded but are independent from each other. Next, the cooled particles are collected by a filter provided on the downstream side of the air flow. At ...

Embodiment 2

[0079] In this example, ferrite particles were produced in the same manner as in Example 1 except that iron oxide and manganese oxide were in a molar ratio of 50:50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com