System and method for eliminating white wake of flue gas

A flue gas and wake technology, which is applied in the field of systems for eliminating the white wake of the flue gas, can solve the problems of high operating costs, inconsistent with the development direction of energy saving and consumption reduction, and high consumption of electricity and heat, so as to reduce the contribution and eliminate the white wake. , the effect of reducing relative humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

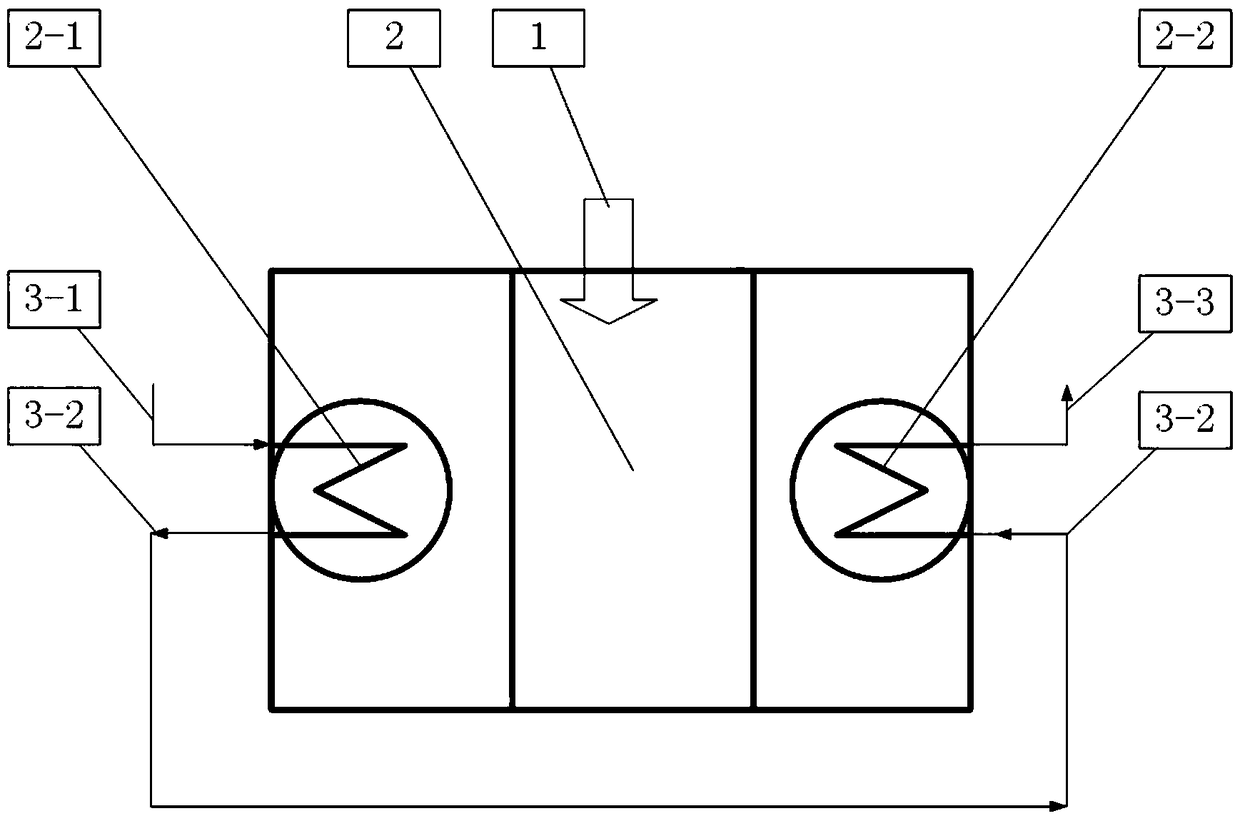

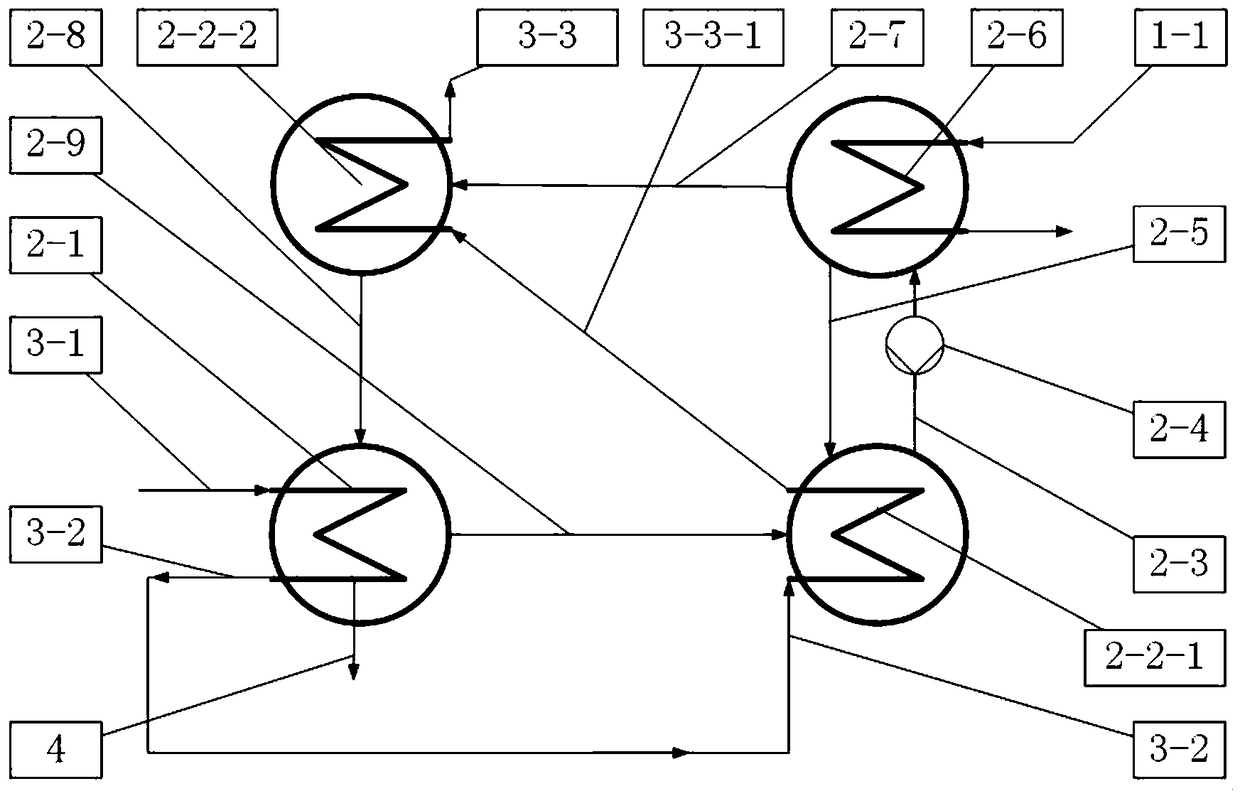

[0040] Such as figure 2 , using an absorption heat pump, the absorption heat pump driving energy is steam or high-temperature flue gas 1-1 to drive the heat pump 2 to work, when the heat pump 2 is working, the flue gas 3-1 to be treated enters the flue gas cooling unit 2-1 of the heat pump, Cooling and cooling, and the water in the flue gas condenses and precipitates, and the condensed water 4 is recovered by the condensed water recovery unit, which can be reused to save water resources. The amount of condensed water 4 is equal to the amount of water contained in the flue gas 3-1 to be treated minus the cooling The amount of water contained in the cooled flue gas 3-3, the water in the flue gas condenses in the process to take out the fine particle pollutants and soluble pollutants in the flue gas, so that the flue gas finally discharged into the atmosphere 3- 3 Cleaner and cleaner, the cooled flue gas 3-2 comes out of the flue gas cooling unit 2-1, then enters the flue gas he...

Embodiment 2

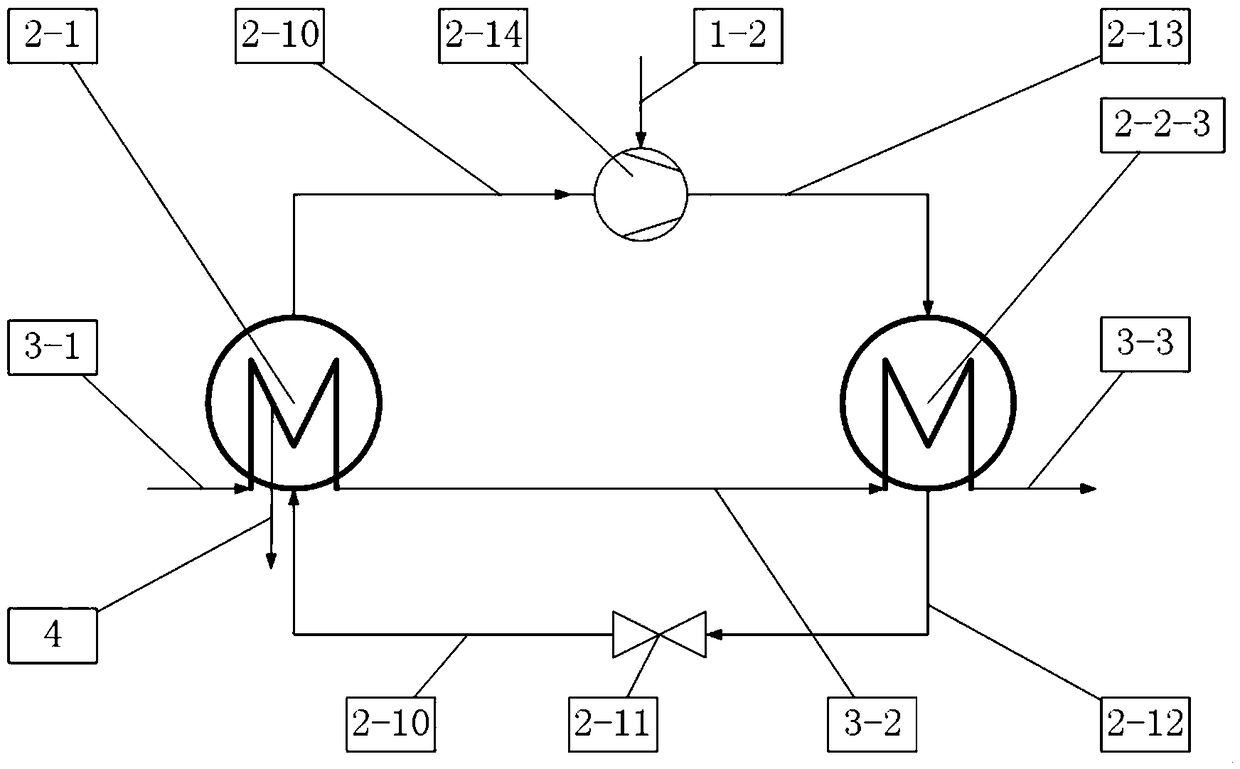

[0043] Such as image 3 , using a compressor heat pump to implement, the compression heat pump drives energy 1-2 to drive the compression heat pump compressor 2-14 to work, and drives the heat pump 2 to work. When the heat pump 2 is working, the compression heat pump gaseous expansion working medium 2-10 is The heat pump compresses 2-14 to become a compression heat pump high temperature and high pressure gaseous working medium 2-13. In the flue gas heating unit 2-2, the high temperature and high pressure working medium 2-13 passes through the compression heat pump condenser 2-2-3, The heat is transferred to the flue gas to be heated 3-2 to become a compression heat pump low-temperature high-pressure liquid working fluid 2-12, and the flue gas to be heated 3-2 absorbs the heat of the liquid high-temperature working fluid in the heat pump condenser 2-2-3 Heated into high-temperature flue gas 3-3, the heated flue gas 3-3 is discharged into the atmosphere without white smoke, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com