Modified zeolite molecular sieve as well as preparation method and application thereof

A zeolite molecular sieve and molecular sieve technology, applied in the field of petroleum exploration, can solve the problems of large diffusion resistance, difficulty in escaping, and long retention time, and achieve the effects of simple operation, increased micropore size, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment firstly provides a kind of zeolite molecular sieve, and it is prepared through the following steps:

[0051] Take 5g of 13X molecular sieve, add it to 80mL oxalic acid ethanol solution with a concentration of 0.1mol / L, stir at 50°C for 2h at 20rpm, then filter with suction, wash until neutral, activate at 450°C for 8h, and Cool in a desiccator for later use.

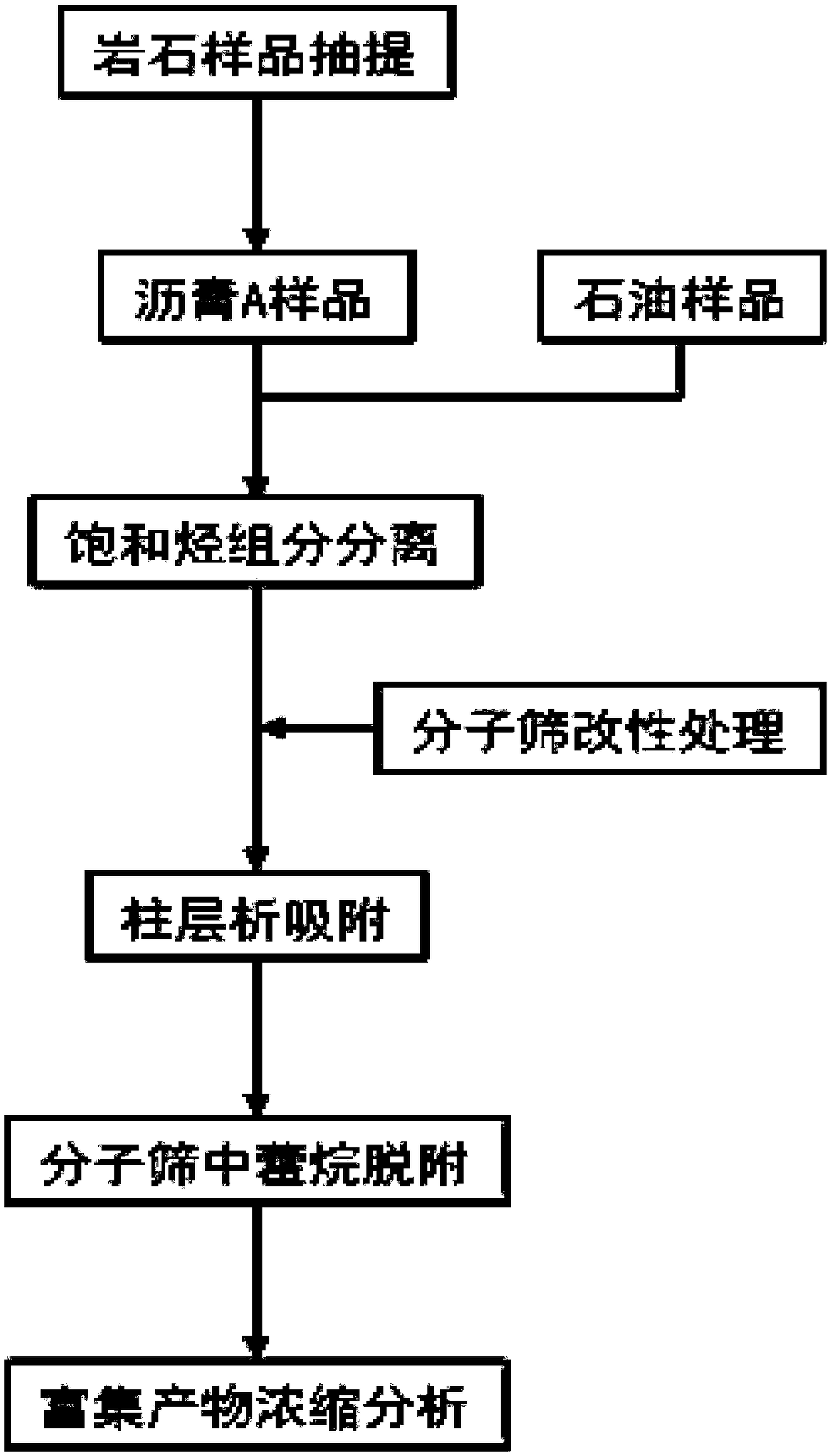

[0052] This embodiment also provides a method for enriching hopane in geological samples, such as figure 1 As shown, it specifically includes the following steps:

[0053] Preparation of saturated hydrocarbon components

[0054] The bitumen A sample or petroleum sample obtained by extracting rock samples is separated by silica gel column or silica gel / alumina column chromatography to obtain saturated hydrocarbon components; the saturated hydrocarbon components are blown to dryness with nitrogen at room temperature and weighed.

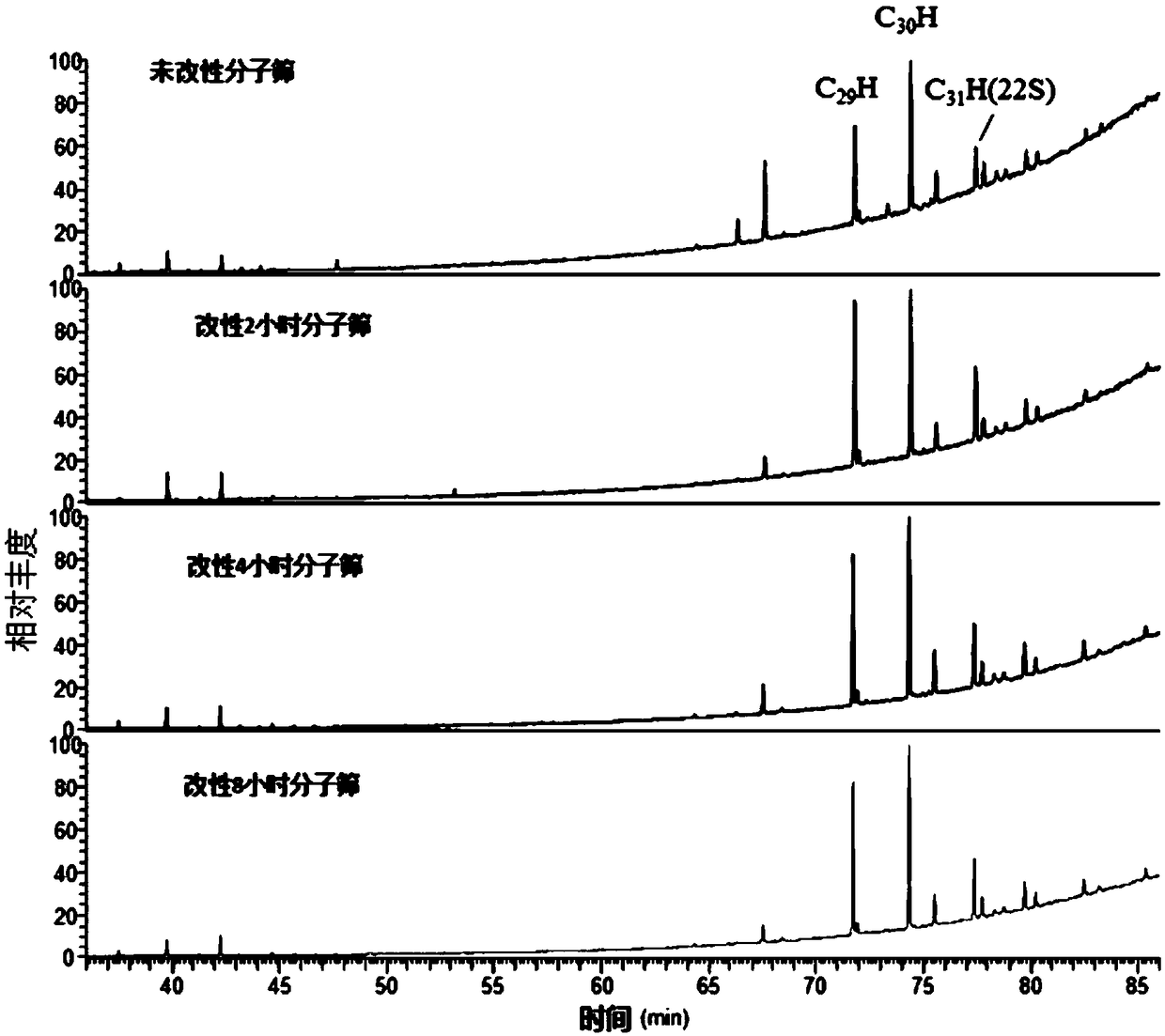

[0055] Molecular Sieve Chromatographic Column Adsorption of Hopanes...

Embodiment 2

[0067] In this example, the isothermal adsorption test was carried out on unmodified 13X molecular sieve, 13X molecular sieve modified with oxalic acid for 2 hours, and 13X molecular sieve modified with oxalic acid for 8 hours. The average pore size of the molecular sieve increased from 0.6685nm unmodified to modified 0.9200nm for 8 hours. Depend on Figure 3a , Figure 3b , Figure 3c , Figure 4a , Figure 4b , Figure 4c , Figure 5a , Figure 5b ,and Figure 5c It can be seen that the modified molecular sieve retains the original structural features of the molecular sieve, and the pores of the modified molecular sieve can be enlarged as required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com