High-temperature crystalline glaze and preparation method thereof

A high-temperature crystallization and glaze slurry technology, applied in the field of ceramic glaze, can solve the problems of long firing time and holding time, high firing conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

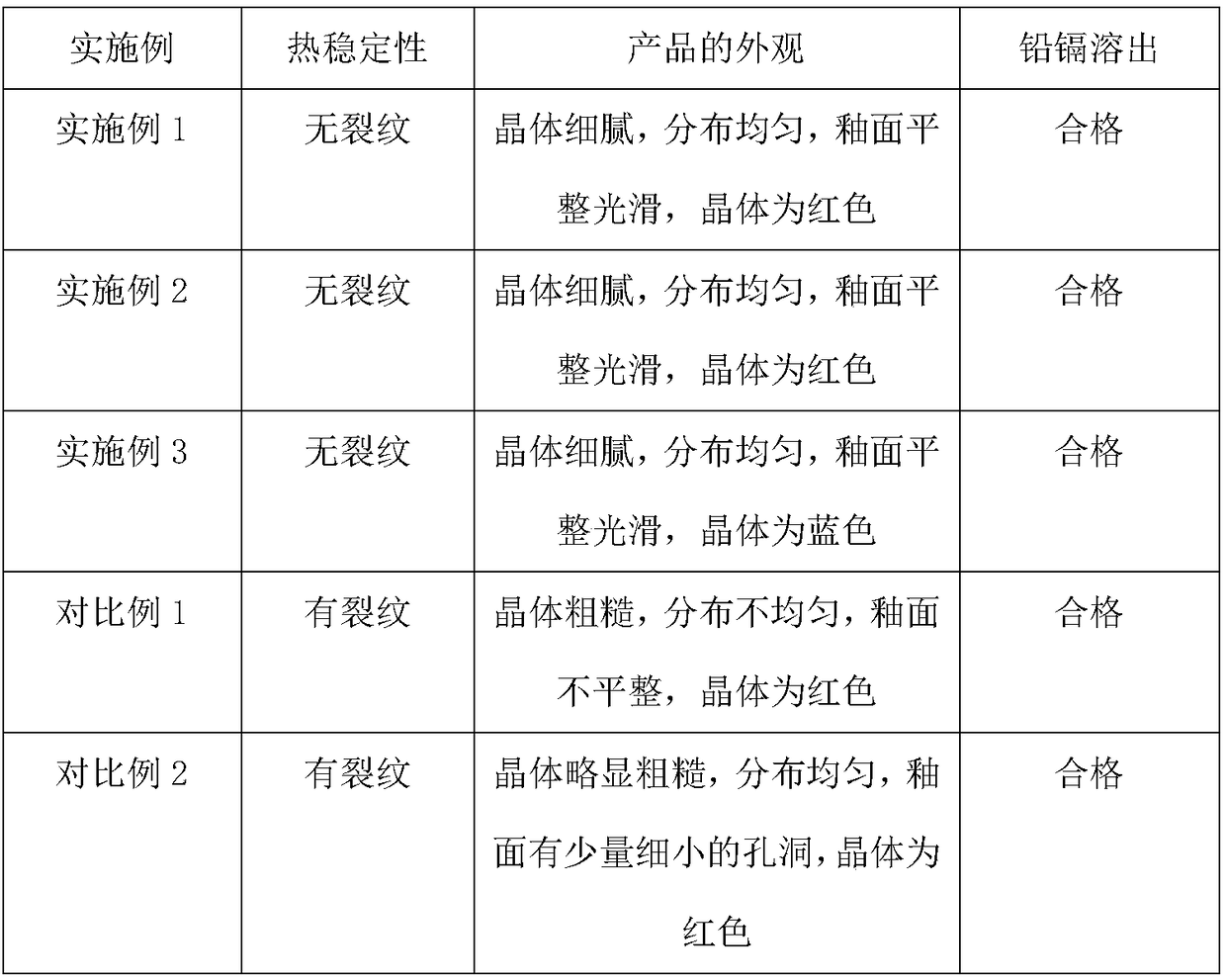

Embodiment 1

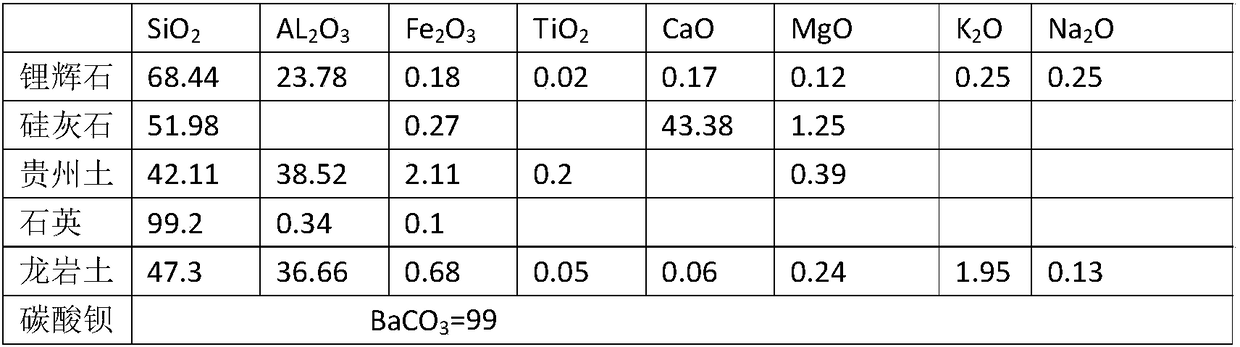

[0040] High-temperature crystalline glaze, including the following components and their respective weight percentages: 7% of spodumene, 48% of wollastonite powder, 4% of Guizhou soil, 8% of quartz powder, 4% of Longyan soil, 28% of barium carbonate, and 1% of copper oxide %.

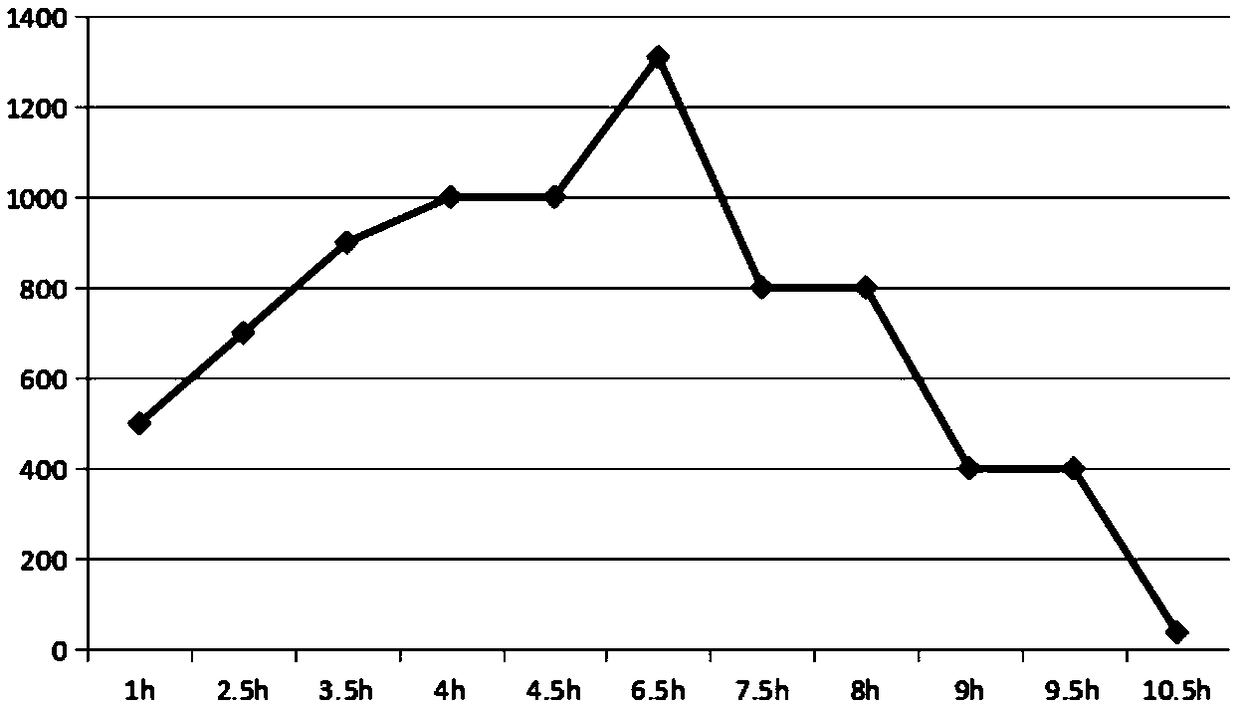

[0041] The preparation method of high-temperature crystalline glaze: 1) Prepare materials according to each component and the mass percentage of each component, put the raw materials into a ball mill, and add an appropriate amount of water, and wet ball mill for 22 hours to obtain a fineness of 0.02 fineness passing through a 250 mesh sieve. -0.04% glaze, the glaze passes through a 120-mesh sieve to obtain glaze slurry; wherein the mass ratio of raw materials, ball stones, and water is 1:2:0.5, among high alumina ball stones, large ball stones, medium ball stones, and small ball stones The mass ratio of ball stone is 2:5:3;

[0042] 2) Add water to adjust the concentration of the glaze slurry to 45 degr...

Embodiment 2

[0044] High temperature crystalline glaze, including the following components and their respective weight percentages: spodumene 8%, wollastonite powder 46%, Guizhou soil 5%, quartz powder 6.5%, Longyan soil 6%, barium carbonate 30%, copper oxide 0.5% %.

[0045] The preparation method of high-temperature crystalline glaze: 1) prepare materials according to each component and the mass percentage of each component, add the raw materials into the ball mill, and add an appropriate amount of water, and wet ball mill together for 24 hours to obtain a fineness of 0.02 over 250 mesh sieve. -0.04% glaze, the glaze passes through a 120-mesh sieve to obtain glaze slurry; wherein the mass ratio of raw materials, ball stones, and water is 1:2:0.5, among high alumina ball stones, large ball stones, medium ball stones, and small ball stones The mass ratio of ball stone is 2:5:3;

[0046] 2) Add water to adjust the concentration of the glaze slurry to 43 degrees Baume, then attach the glaze...

Embodiment 3

[0048] High-temperature crystalline glaze, including the following components and their respective weight percentages: 10% of spodumene, 45% of wollastonite powder, 4.5% of Guizhou soil, 7% of quartz powder, 5% of Longyan soil, 28% of barium carbonate, and 0.5% of cobalt oxide %.

[0049] The preparation method of high-temperature crystalline glaze: 1) prepare materials according to each component and the mass percentage of each component, add the raw materials into the ball mill, and add an appropriate amount of water, and wet ball mill together for 24 hours to obtain a fineness of 0.02 over 250 mesh sieve. -0.04% glaze, the glaze passes through a 120-mesh sieve to obtain glaze slurry; wherein the mass ratio of raw materials, ball stones, and water is 1:2:0.5, among high alumina ball stones, large ball stones, medium ball stones, and small ball stones The mass ratio of ball stone is 2:5:3;

[0050] 2) Add water to adjust the concentration of the glaze slurry to 46 Baume degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com