Method for preparing SiC aerogel through ultrasonic-mixing silicon source and carbon source

A technology of mixing silicon source and airgel, which is applied in the field of airgel, can solve the problems of no pores and high cost, and achieve the effects of good pore integrity, low sintering temperature, and maintenance of pore integrity and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

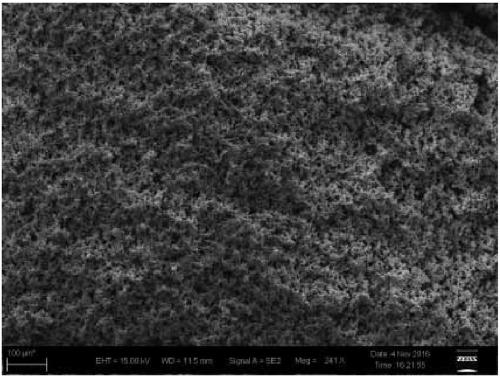

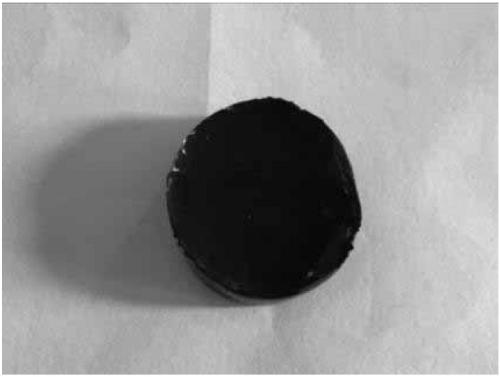

Image

Examples

specific Embodiment approach 1

[0029] Embodiment 1: In this embodiment, the method for preparing SiC airgel by ultrasonically mixing silicon source and carbon source is carried out according to the following steps:

[0030] 1. Preparation of SiC precursor: Mix water glass and acid solution with a concentration of 0.5-10mol / L according to the molar ratio of 1:1.5, and stir for 10-60min under the condition of 0-50°C to make SiC Acid, using alcohol analysis method, standing at 0-50°C for 10-60min to remove sodium salt, adding carbon source, ultrasonic mixing at 30°C-50°C for 0.5-1.5h, wherein the molar ratio of water glass to carbon source 1~5:1;

[0031] 2. Preparation of SiC airgel: add ammonia water with a concentration of 0.5-5 mol / L to the liquid obtained in step 1, stir until the pH value is 8.5-11, and let stand at 0-50°C for 3-30 minutes to obtain a sol. Use micro-pressure equipment to immerse the fiber felt in the sol, let the gel stand, and perform aging and replacement under the conditions of a tem...

specific Embodiment approach 2

[0032] Embodiment 2: This embodiment is different from Embodiment 1 in that the acid described in step 1 is hydrochloric acid, sulfuric acid or nitric acid. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the alcohol used in the alcohol analysis method described in step one is one of methanol, ethanol, isopropanol, n-butanol and tert-butanol or Several mixes. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com