Anti-crease elastic breathable fabric

A technology for breathable fabrics and fabrics, applied in the field of fiber products, can solve problems such as the limitation of finishing liquid, and achieve the effects of improving anti-wrinkle performance, uniform adhesion, and improving elastic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

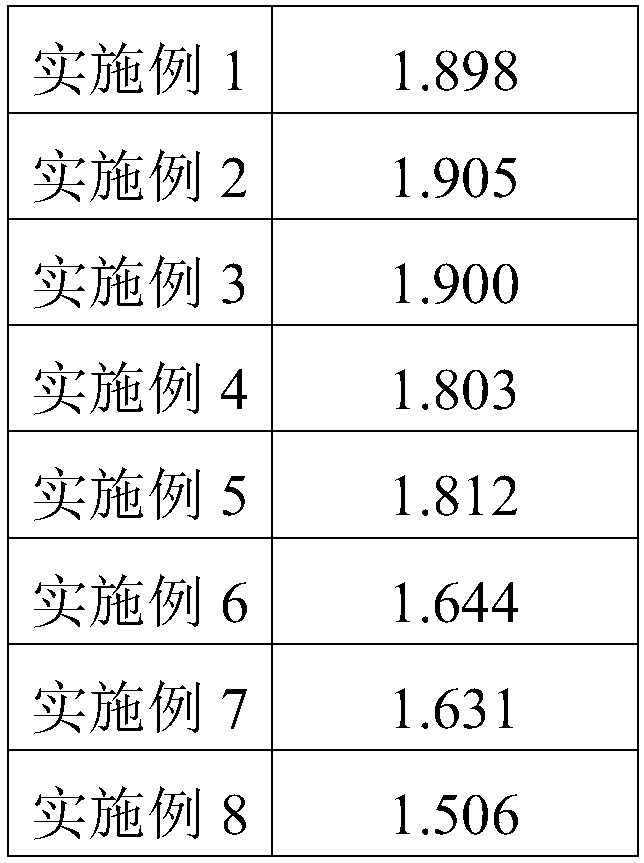

Embodiment 1

[0049] A wrinkle-resistant elastic air-permeable fabric is a tussah silk / ramie fabric finished with lapis lazuli finishing agent;

[0050] The lapis lazuli finishing agent is prepared from the following raw materials in parts by weight: 12 parts of 500-mesh lapis lazuli powder, 24 parts of sodium ethylenediamine di-o-phenylacetate, 5 parts of glycerin, 20 parts of 4-pyrimidinecarboxylic acid, 15 parts of guanidine hydrochloride and 100 parts of water;

[0051] The preparation method of the lapis lazuli finishing agent is to dissolve guanidine hydrochloride in water and heat to 80° C., add lapis lazuli powder, sodium ethylenediamine di-o-phenylacetate, 4-pyrimidinecarboxylic acid and glycerin in sequence, and stir at 300 rpm for 30 minutes. It can be obtained after naturally cooling down to room temperature;

[0052] The following fabric spray consists of 6 parts by weight of 4-methylimidazole, 20 parts of ammonium dihydrogen phosphate, 10 parts of lithium phosphate, 30 parts ...

Embodiment 2

[0065] A wrinkle-resistant elastic air-permeable fabric is a tussah silk / ramie fabric finished with lapis lazuli finishing agent;

[0066] The lapis lazuli finishing agent is prepared from the following raw materials in parts by weight: 12 parts of 500-mesh lapis lazuli powder, 24 parts of sodium ethylenediamine di-o-phenylacetate, 5 parts of glycerin, 20 parts of 2-methyl- 4-pyrimidinecarboxylic acid, 15 parts of guanidine hydrochloride and 100 parts of water;

[0067] The preparation method of the lapis lazuli finishing agent is to dissolve guanidine hydrochloride in water and heat to 80°C, then add lapis lazuli powder, sodium ethylenediamine di-o-phenylacetate, 2-methyl-4-pyrimidinecarboxylic acid and glycerol in sequence, Stir at 300rpm for 30 minutes, then cool down to room temperature naturally;

[0068] The following fabric spray consists of 6 parts by weight of 4-methylimidazole, 20 parts of ammonium dihydrogen phosphate, 10 parts of lithium phosphate, 30 parts of eth...

Embodiment 3

[0081] A wrinkle-resistant elastic air-permeable fabric is a tussah silk / ramie fabric finished with lapis lazuli finishing agent;

[0082] The lapis lazuli finishing agent is prepared from the following raw materials in parts by weight: 12 parts of 500-mesh lapis lazuli powder, 24 parts of sodium ethylenediamine di-o-phenylacetate, 5 parts of glycerin, 20 parts of 2-amino-4 - pyrimidinecarboxylic acid, 15 parts of guanidine hydrochloride and 100 parts of water;

[0083] The preparation method of the lapis lazuli finishing agent is to dissolve guanidine hydrochloride in water and heat to 80°C, then add lapis lazuli powder, sodium ethylenediamine di-o-phenylacetate, 2-amino-4-pyrimidinecarboxylic acid and glycerol in sequence, 300rpm Stir for 30 minutes, then cool down to room temperature naturally;

[0084] The following fabric spray consists of 6 parts by weight of 4-methylimidazole, 20 parts of ammonium dihydrogen phosphate, 10 parts of lithium phosphate, 30 parts of ethanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com