Fuzzy hysteresis current control system and method for permanent magnet synchronous motor

A permanent magnet synchronous motor and hysteresis current technology, which is applied in the control system, current controller, AC motor control, etc., can solve the problems of general system response, current tracking control response speed and unsatisfactory steady-state accuracy, etc., to improve Response speed and steady-state accuracy, the effect of enhancing system stability and robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

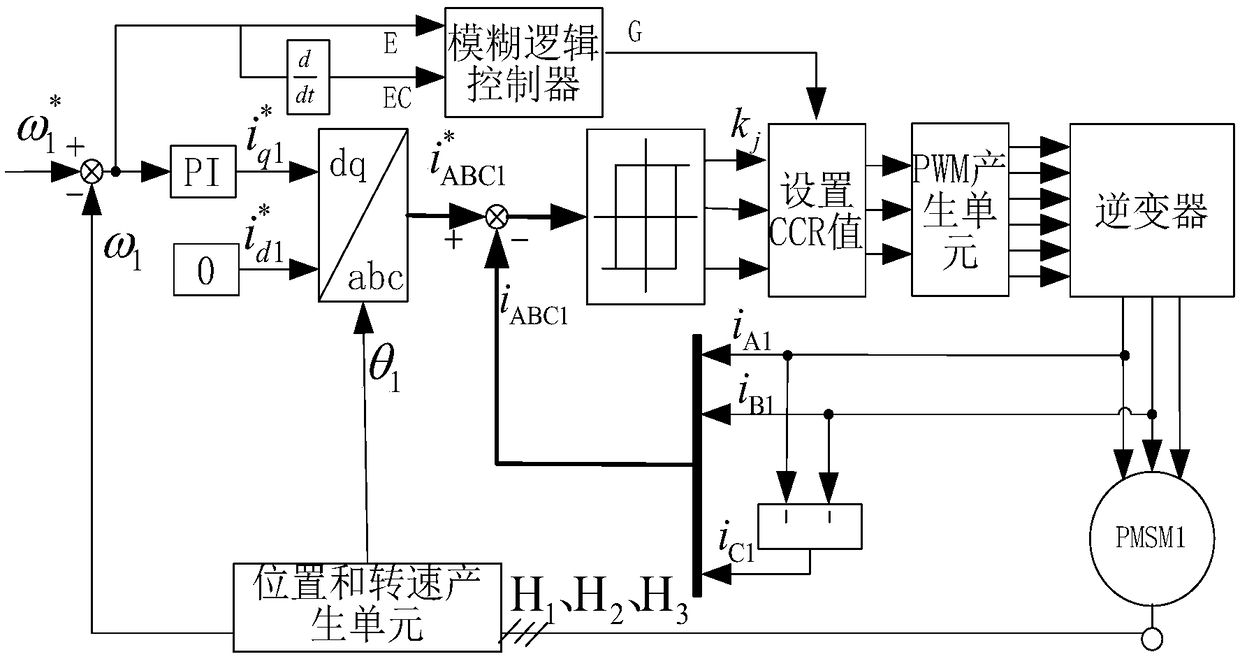

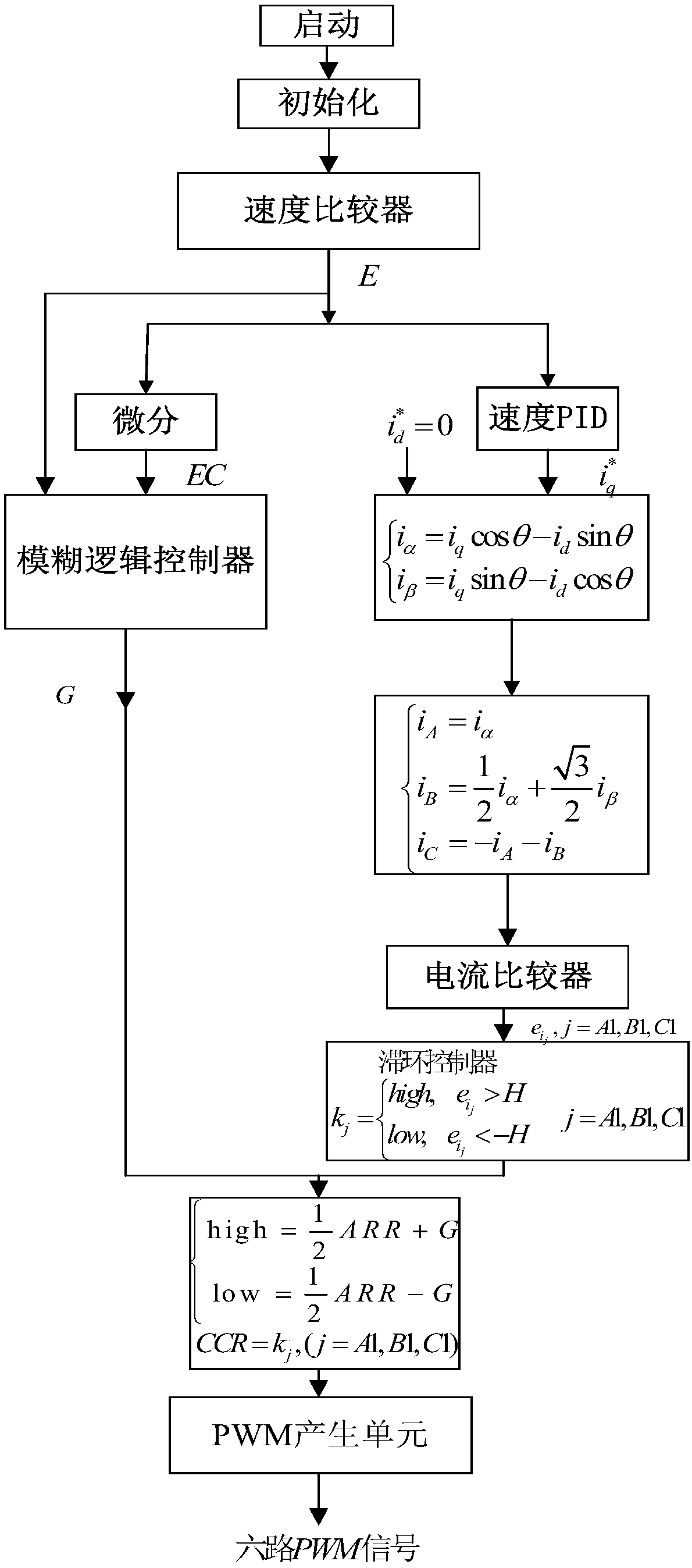

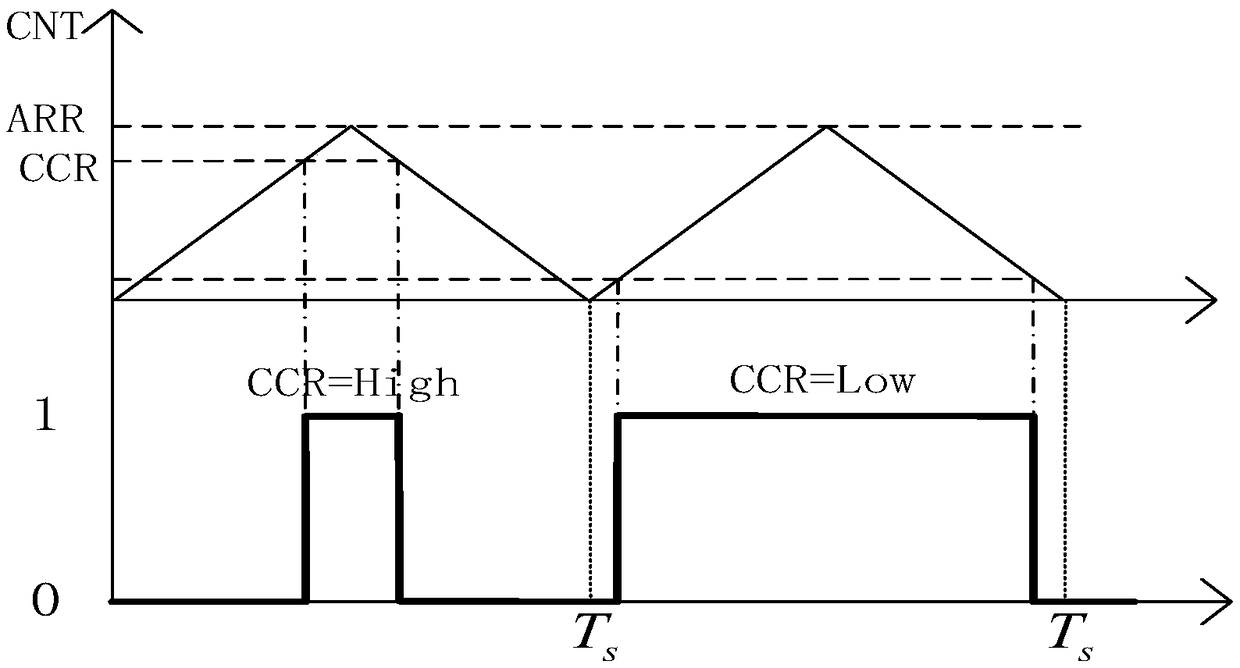

[0051] see figure 1 , the present invention provides a permanent magnet synchronous motor fuzzy hysteresis current control system, including a DC power supply, a fuzzy logic controller, a Park and Clarke conversion module, a hysteresis controller, a PWM generating unit, a PI controller, and a hysteresis controller , differential unit, current sensor, Hall sensor, position and speed generating unit, inverter, current regulator, speed regulator;

[0052] The DC power supply is connected with each bridge arm of the inverter; the speed regulator is connected with the fuzzy logic controller, the differential unit, the position and speed generating unit and the PI controller, and the PI controller is connected with the Park and Clarke conversion modules, and the Park and Clarke conversion modules are connected. The Clarke conversion module is connected with the current regulator, position and speed generation unit, the current regulator is connected with the current sensor and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com