Non hot processing treatment technology for improving quality of coix seed whole powder to improve quality of wheat flour and coix seed whole powder

A non-thermal processing and processing technology is applied in the field of nutritional quality of barley whole flour and wheat flour, which can solve the problems of nutrient loss, influence on edible sensory quality, and deterioration of processing quality of wheat flour.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

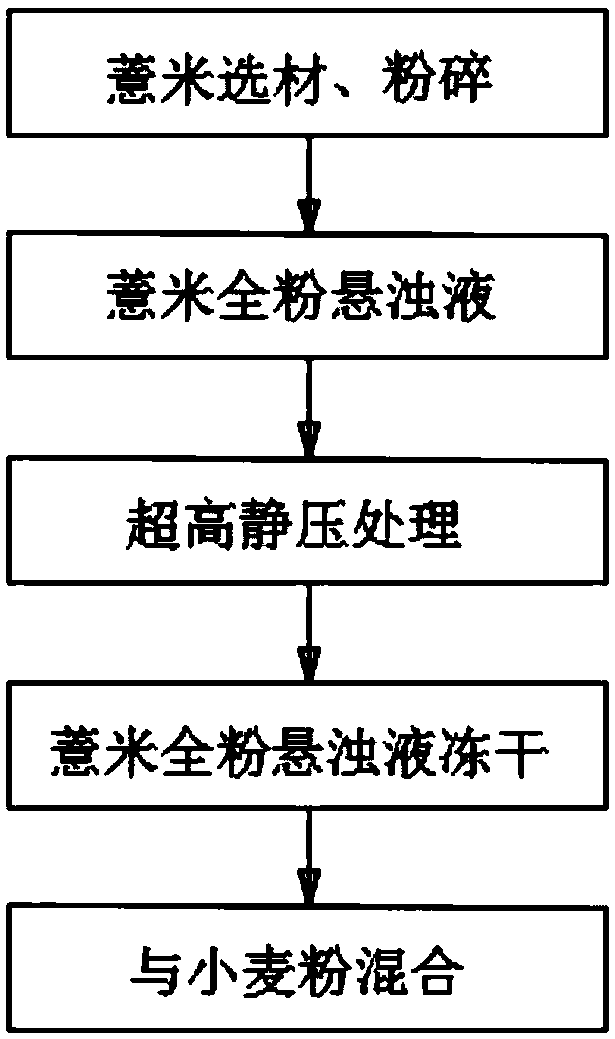

Method used

Image

Examples

Embodiment example 1

[0030] Step 1: select high-quality barley raw materials, use a traditional Chinese medicine grinder to crush the barley, and pass the whole powder of the barley after crushing through an 80-mesh sieve. Step 2, the whole powder of Job's tears is dissolved in a beaker according to a certain material-to-liquid ratio of 1:5, and the obtained suspension is moved to an aluminum foil bag, and sealed with a vacuum packaging machine, and the material-to-liquid ratio is a mass-to-volume ratio. Step 3, this does not undergo ultra-high static pressure treatment, but it needs to go through step 4. Put the suspension of barley powder and the container directly in the freeze dryer for drying. The vacuum degree is 50±5Pa, and the temperature of the heating plate is 30°C. The drying time is 8 hours; finally, according to a certain mass ratio of 10%, it is mixed with wheat flour to form a compound flour of whole flour of wheat flour and barley.

Embodiment example 2

[0032] Step 1: select high-quality barley raw materials, use a traditional Chinese medicine grinder to crush the barley, and pass the whole powder of the barley after crushing through an 80-mesh sieve. Step 2, the whole powder of Job's tears is dissolved in a beaker according to a certain material-to-liquid ratio of 1:5, and the obtained suspension is moved to an aluminum foil bag, and sealed with a vacuum packaging machine, and the material-to-liquid ratio is a mass-to-volume ratio. Step 3: Put it into ultra-high static pressure equipment for ultra-high static pressure treatment, increase the pressure to 200MPa, the pressure increase rate is 400MPa / min, and keep the pressure for 15 minutes. After the time is up, the machine automatically releases the pressure quickly, and the pressure relief rate is 400MPa / min . Step 4. The ultra-high static pressure treated coix seed powder suspension and the container are directly placed in a freeze dryer for drying at a vacuum degree of 50...

Embodiment example 3

[0034] Step 1: select high-quality barley raw materials, use a traditional Chinese medicine grinder to crush the barley, and pass the whole powder of the barley after crushing through an 80-mesh sieve. Step 2. The whole powder of Job’s tears is dissolved in a beaker according to a certain material-to-liquid ratio of 1:3-1:7, and the obtained suspension is moved to an aluminum foil bag, and sealed with a vacuum packaging machine. The material-to-liquid ratio is mass to volume ratio. Step 3: Put in ultra-high static pressure equipment for ultra-high static pressure treatment, increase the pressure to 300MPa, the pressure increase rate is 400MPa / min, keep the pressure for 15 minutes, and the machine will automatically release the pressure quickly after the time is up, and the pressure relief rate is 400MPa / min . Step 4. The ultra-high static pressure-treated coix seed powder suspension and the container are directly placed in a freeze dryer for drying, the vacuum degree is 50±5P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com