A kind of preparation method of activated carbon fiber/graphene tube composite material

A technology of activated carbon fibers and graphene tubes, applied in chemical instruments and methods, alkali metal compounds, water/sewage treatment, etc., can solve the problems of harsh experimental conditions and high cost, and achieve excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

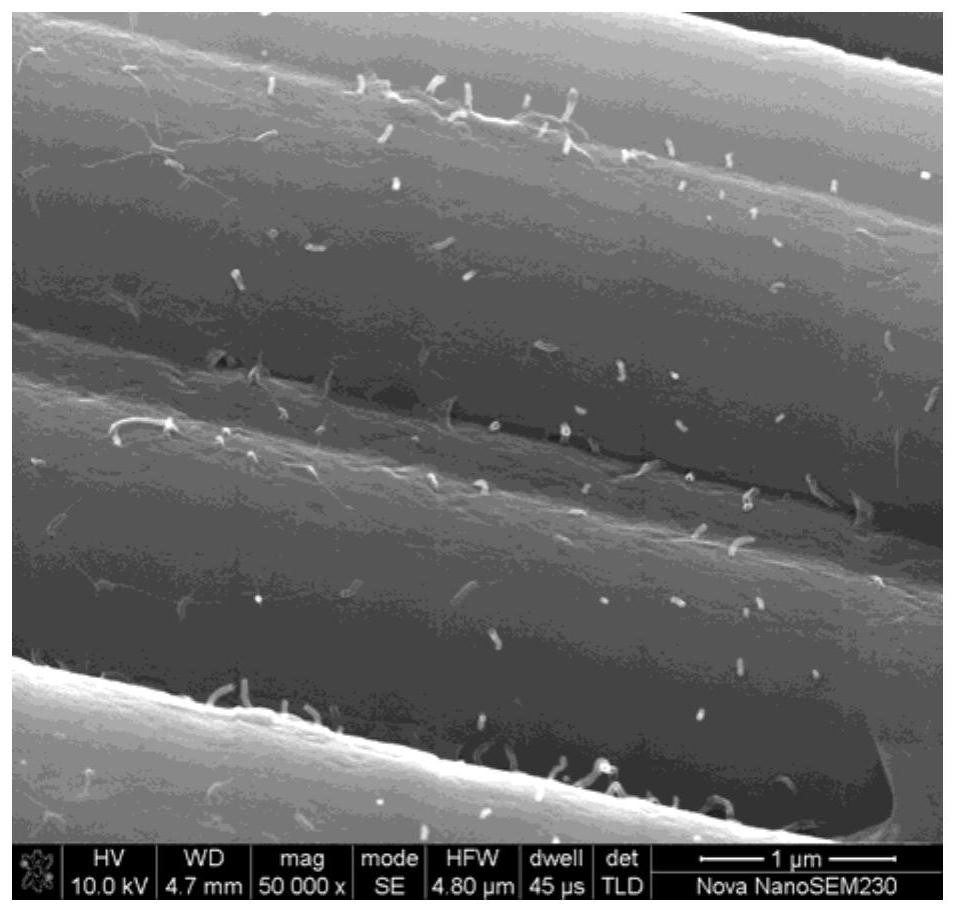

Image

Examples

Embodiment 1

[0019] (1) Graphene oxide was prepared by the improved Hummers method. That is: add H 2 SO 4 / H 3 PO 4 (360mL:40mL) 9:1 mixture to 3.0g graphite and 18.0g KMnO 4 In the mixture, a small amount of heat is generated to raise the temperature to 35-40°C. Then heated to 50 ° C, stirring the reaction for 12h. The reaction solution was cooled to room temperature, and a certain amount of ice water and 30% H 2 o 2 , making the solution bright yellow. Then, it was washed with 5% HCl solution and deionized water until no sulfate group was detected in the filtrate.

[0020] (2) Centrifuge the dispersion obtained in (1), remove the unoxidized graphite in the lower part, and keep the supernatant. That is, a graphene oxide solution is obtained.

[0021] (3) The graphene oxide solution prepared in (2) was diluted with deionized water to a concentration of 5 mg / mL and ultrasonicated for 6 hours at a frequency of 100 KHz and a power of 800 W to obtain the desired graphene oxide soluti...

Embodiment 2

[0025] (1) Graphene oxide was prepared by the improved Hummers method. That is: add H 2 SO 4 / H 3 PO 4 (360mL:40mL) 9:1 mixture to 3.0g graphite and 18.0g KMnO 4 In the mixture, a small amount of heat is generated to raise the temperature to 35-40°C. Then heated to 50 ° C, stirring the reaction for 12h. The reaction solution was cooled to room temperature, and a certain amount of ice water and 30% H 2 o 2 , making the solution bright yellow. Then, it was washed with 5% HCl solution and deionized water until no sulfate group was detected in the filtrate.

[0026] (2) Centrifuge the dispersion obtained in (1), remove the unoxidized graphite in the lower part, and keep the supernatant. That is, a graphene oxide solution is obtained.

[0027] (3) The graphene oxide solution prepared in (2) was diluted with deionized water to a concentration of 3 mg / mL and ultrasonicated for 4 hours at a frequency of 100 KHz and a power of 800 W to obtain the desired graphene oxide soluti...

Embodiment 3

[0031] (1) Graphene oxide was prepared by the improved Hummers method. That is: add H 2 SO 4 / H 3 PO 4 (360mL:40mL) 9:1 mixture to 3.0g graphite and 18.0g KMnO 4 In the mixture, a small amount of heat is generated to raise the temperature to 35-40°C. Then heated to 50 ° C, stirring the reaction for 12h. The reaction solution was cooled to room temperature, and a certain amount of ice water and 30% H 2 o 2 , making the solution bright yellow. Then, it was washed with 5% HCl solution and deionized water until no sulfate group was detected in the filtrate.

[0032] (2) Centrifuge the dispersion obtained in (1), remove the unoxidized graphite in the lower part, and keep the supernatant. That is, a graphene oxide solution is obtained.

[0033] (3) The graphene oxide solution prepared in (2) was diluted with deionized water to a concentration of 8 mg / mL and ultrasonicated for 8 hours at a frequency of 100 KHz and a power of 800 W to obtain the desired graphene oxide soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com