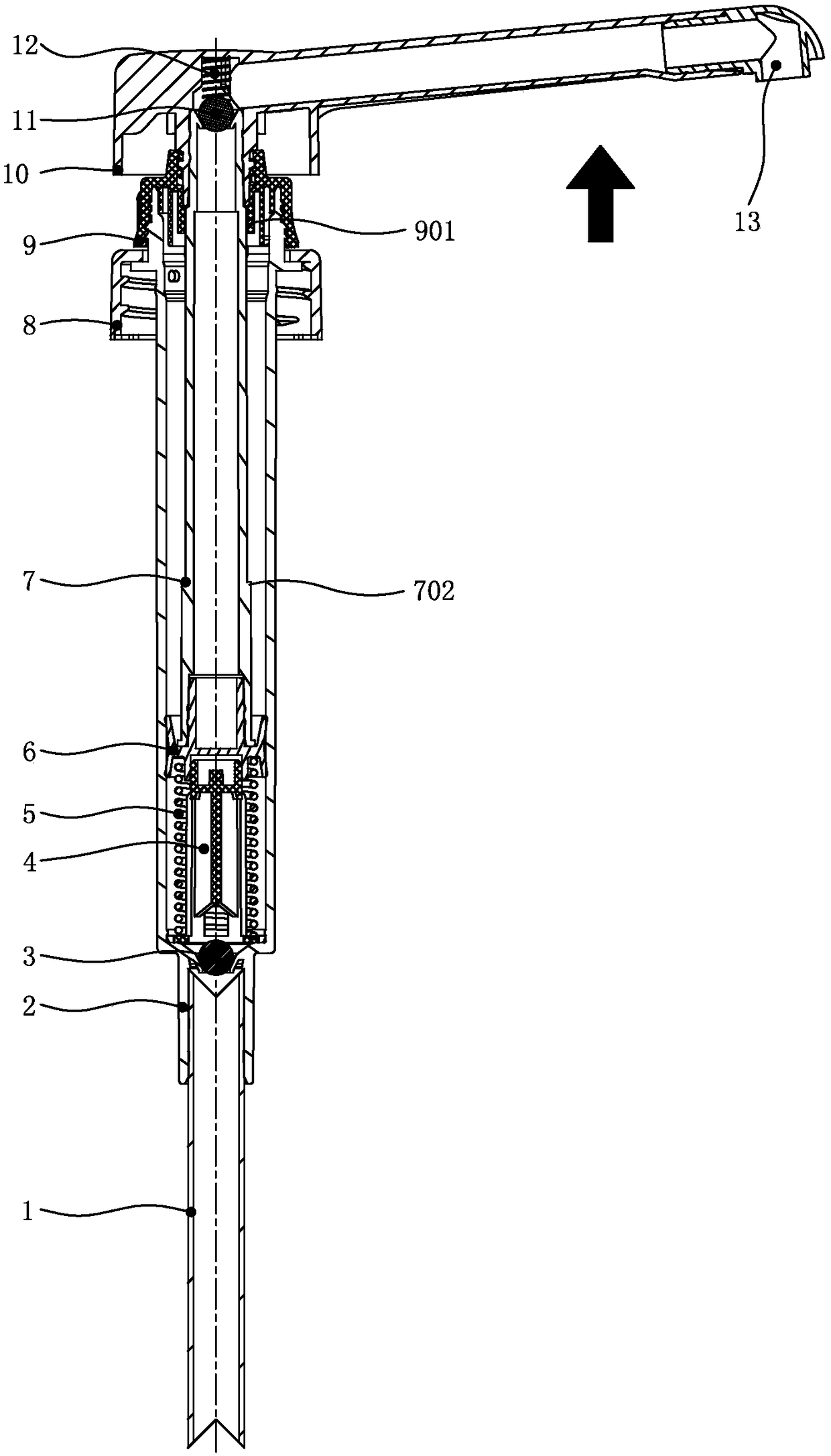

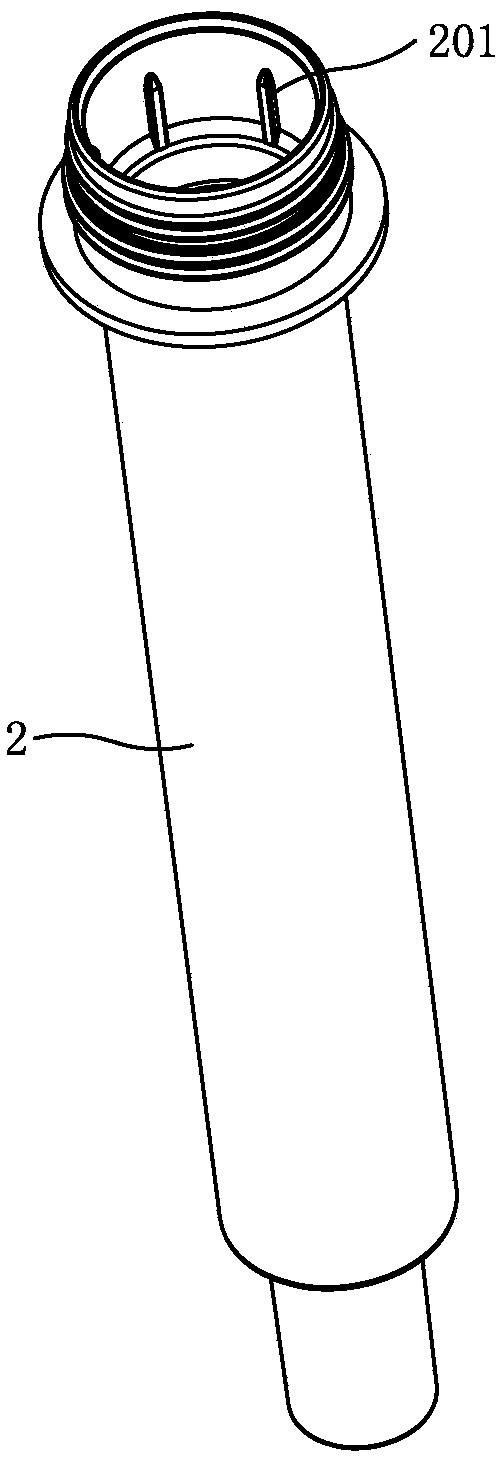

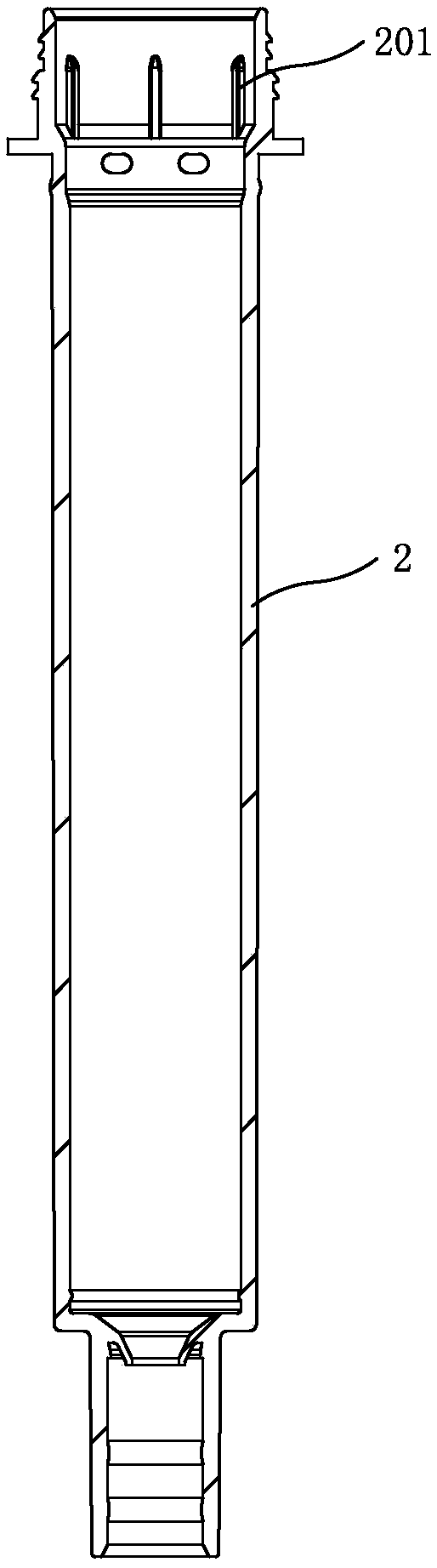

Ultraviolet-proof anti-static emulsion pump and preparation method thereof

An anti-ultraviolet and anti-static technology, which is applied in the field of lotion pumps, can solve problems such as poor design of the connection structure between the connecting seat and the pump body, lack of anti-ultraviolet anti-static materials, difficult adjustment of the valve stem, etc., and achieve a feasible preparation method and a long service life , good sealing and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The raw materials and dosage are: 50 grams of polylactic acid, 2 grams of ultraviolet absorber, 1 gram of UV protection antioxidant, 0.5 gram of graphene, 1 gram of aluminum-titanium composite coupling agent, and 1 gram of HDC-102 antistatic agent. , 2.5 g acetyl tributyl citrate plasticizer, 1.25 g lubricant aluminum stearate. Polylactic acid was dried in a vacuum oven at 80°C for 12 hours; TMC-300 nucleating agent was dried in a vacuum oven at 80°C for 2 hours. Then mix the raw materials evenly and put them into the internal mixer for melting and mixing. The temperature of the three parts of the internal mixer is 190°C, 195°C and 190°C respectively, the rotating speed is 40rmp, and the internal mixing time is 10 minutes. After extrusion at the head of the screw machine, the melted and mixed resin is hot-pressed in the mold and preheated for 5 minutes; the hot-pressing temperature of the upper and lower dies is 190 ° C, and the pressure is 10 MPa; the hot-pressing time...

Embodiment 2

[0030] The raw materials and dosage are: 25 grams of polybutylene succinate, 25 grams of polylactic acid, 1.5 grams of ultraviolet absorber, 1 gram of UV protection and antioxidant, 0.5 grams of graphene, 1 gram of aluminum-titanium composite coupling agent , 1 g HDC-102 antistatic agent. 0.25 grams of TMC-306 nucleating agent, 0.25 grams of maleic anhydride, 2.5 grams of acetyl tributyl citrate plasticizer, 1.25 grams of lubricant aluminum stearate. Polybutylene succinate and polylactic acid were dried in a vacuum oven at 80°C for 12 hours; TMC-306 nucleating agent was dried in a vacuum oven at 80°C for 2 hours. Then mix the raw materials evenly and put them into the internal mixer for melting and mixing. The temperature of the three parts of the internal mixer is 190°C, 195°C and 190°C respectively, the rotating speed is 40rmp, and the internal mixing time is 10 minutes. After being extruded at the head of the screw machine, the melted and mixed resin is hot-pressed in the ...

Embodiment 3

[0032] The raw materials and dosage are respectively: 20 grams of polyhydroxyalkanoate, 15 grams of polybutylene succinate, 25 grams of polylactic acid, 2 grams of ultraviolet absorbers, 1.5 grams of UV-resistant antioxidants, 0.75 grams of graphene, 1 gram of aluminum-titanium composite coupling agent, 1 gram of HDC-102 antistatic agent. 0.25 grams of maleic anhydride, 0.25 grams of TMC-306 nucleating agent, 2.5 grams of acetyl tributyl citrate plasticizer, 1.25 grams of lubricant aluminum stearate. Polyhydroxyalkanoate, polybutylene succinate and polylactic acid were dried in a vacuum oven at 80°C for 12 hours; TMC-306 nucleating agent was dried in a vacuum oven at 80°C for 2 hours. Mix the raw materials evenly and put them into the internal mixer for melting and mixing. The temperature of the three parts of the internal mixer is 190°C, 195°C and 190°C respectively, the rotational speed is 40rmp, and the internal mixing time is 10 minutes. After being extruded at the head o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com