BTS (Ba2TiSi2O8) piezoelectric crystal cut type and application thereof

A piezoelectric crystal and titanium silicate technology, which is applied in the cutting shape of titanium barium silicate piezoelectric crystal and its application fields, can solve the problems of the influence of material properties, etc., achieves large piezoelectric coefficient, high voltage electric constant, and simple processing method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

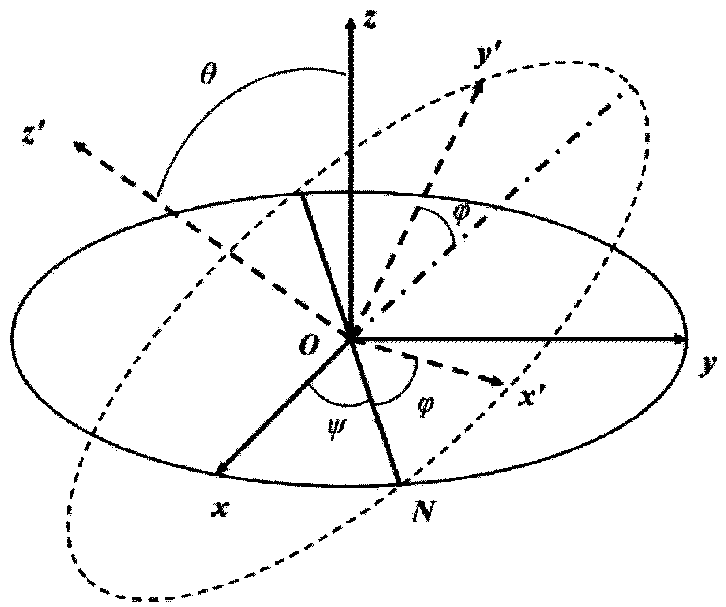

[0044] A barium titanium silicate piezoelectric crystal cut type, for the tetragonal barium titanium silicate crystal, the physical coordinate axes X, Y and Z axes are respectively parallel to the crystallographic coordinate axes a, b and c axes, and the piezoelectric coefficient of the crystal is d 33 The positive value is the +Z axis, the negative value is the -Z axis, and the Z-axis direction of the titanium barium silicate crystal is determined. The cut shape of the titanium barium silicate piezoelectric crystal is any Cutting at an angle of θ can obtain a cut shape with a high piezoelectric constant and a linear thermal expansion coefficient, which is denoted as (θ, ψ), θ=46°, ψ is any angle, and the sample cut shape and processing angle are as follows: Figure 5 shown.

[0045] Verification of barium titanosilicate piezoelectric crystal with large piezoelectric constant:

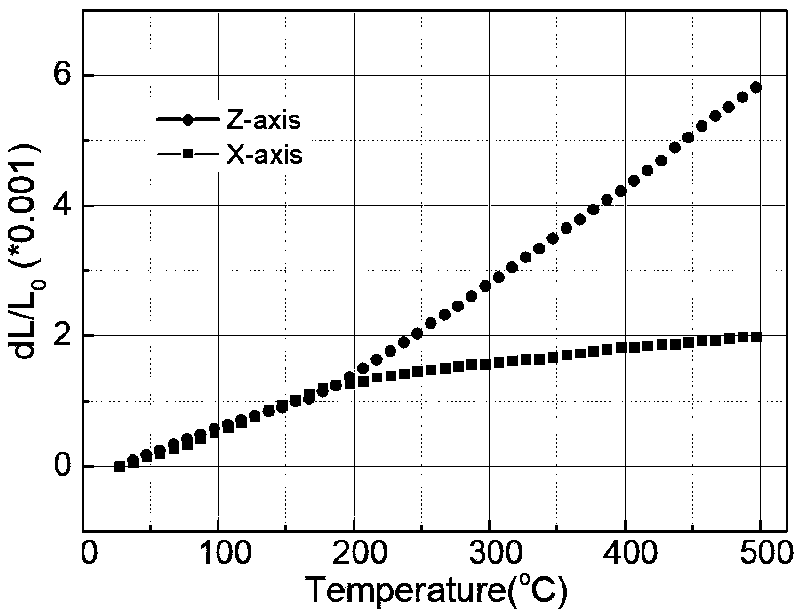

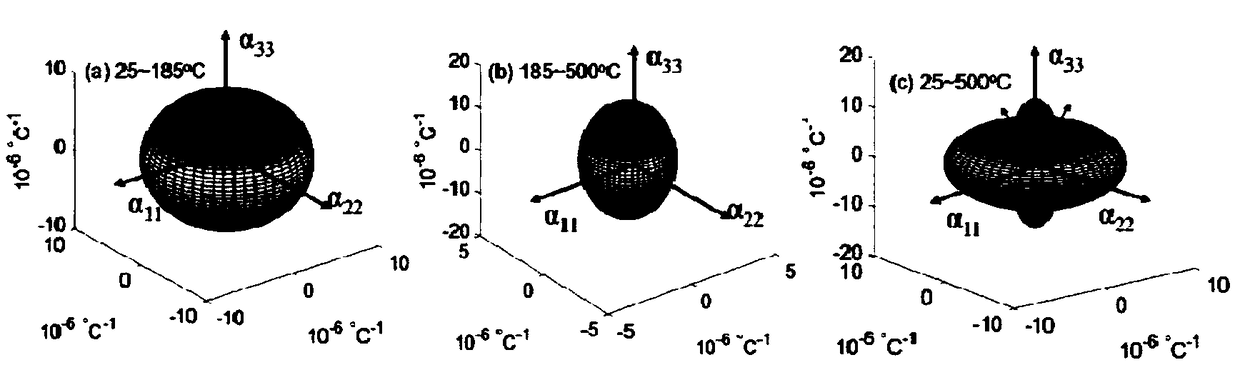

[0046] Pole figures of thermal expansion through barium titania silicate crystals in different te...

Embodiment 2

[0058] Barium titanium silicate piezoelectric crystal cut as described in Example 1, the difference is: θ=47 °, ψ is any angle, the sample cut and processing angle are as follows Figure 5 Shown; the ratio of processing cut size is length:width:thickness==3:4:5, test the change of the size in the thickness direction with temperature in the range of 25°C-500°C, and obtain the effective thermal expansion coefficient α in this direction * 33 8.0ppm / °C.

Embodiment 3

[0060] Barium titanium silicate piezoelectric crystal cut as described in Example 1, the difference is: θ=48 °, ψ is any angle, the sample cut and processing angle are as follows Figure 5 Shown; the ratio of processing cut size is length:width:thickness==3:4:5, test the change of the size in the thickness direction with temperature in the range of 25°C-500°C, and obtain the effective thermal expansion coefficient α in this direction * 33 It is 8.1ppm / °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com