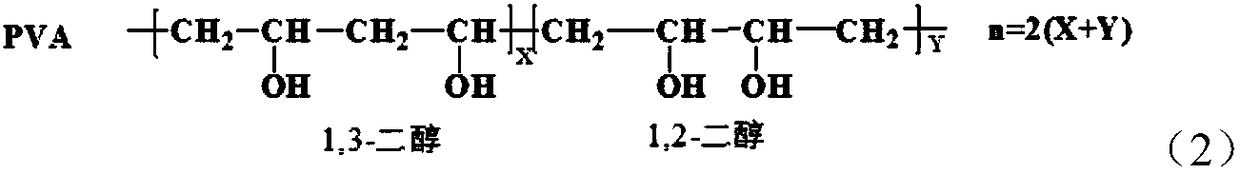

Method for determining contents of 1,2-diol connection structures in polyvinyl alcohol

A technology of polyvinyl alcohol and polyvinyl alcohol solution, applied in measuring devices, chemical method analysis, chemical analysis by titration, etc., can solve the problems of complex instruments and operating techniques for viscosity measurement, and achieve stable data and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

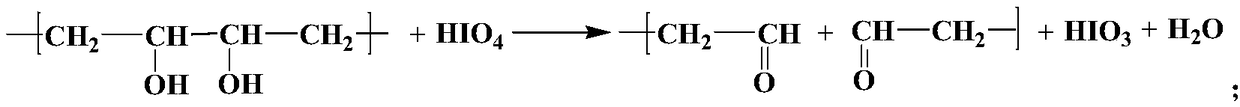

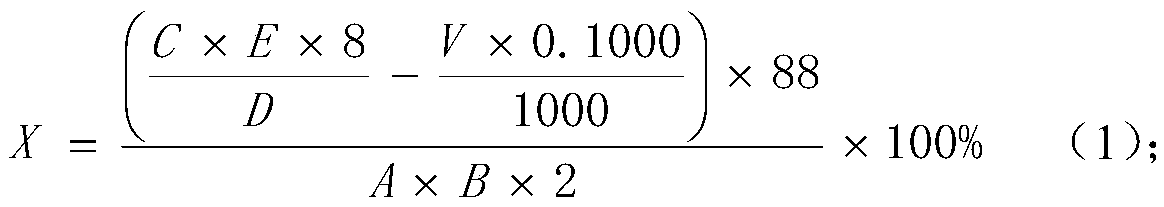

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, the raw material to be tested—polyvinyl alcohol with a purity of 95% (polymerization degree of 1700 and degree of alcoholysis of 99%) is used to verify the accuracy of the method of the present invention. , the specific steps are as follows:

[0035] (1) Weigh A g of polyvinyl alcohol to be tested and add it to a conical beaker, then add 100mL of deionized water, heat up to 90°C, stir until completely dissolved, and then cool to room temperature to obtain a polyvinyl alcohol solution, wherein, A is respectively 0.546g (recorded as test 1), 0.5589g (recorded as test 2), 0.5816g (recorded as test 3).

[0036] (2) Add 3 mL of 0.1000 mol / L dilute hydrochloric acid and C g sodium periodate (purity E is 99.5%) to the polyvinyl alcohol solution, shake and shake well, and react for 5 minutes; after the reaction is completed, add Take 0.6g of potassium iodide, shake well, and place in the dark for 10 minutes to obtain the titration solution; corresponding to...

Embodiment 2

[0041] In this embodiment, the raw material to be tested—polyvinyl alcohol with a purity of 94.5% (degree of polymerization 500, degree of alcoholysis 98.7%) is used to verify the accuracy of the method of the present invention. , the specific steps are as follows:

[0042] (1) Weigh 0.5192g of polyvinyl alcohol to be tested and add it to a conical beaker, then add 100mL of deionized water, heat up to 90°C, stir until completely dissolved, then cool to room temperature to obtain a polyvinyl alcohol solution.

[0043] (2) Add 6mL of 0.1000mol / L dilute hydrochloric acid and 0.0767g of sodium periodate (purity: 99.5%) to the polyvinyl alcohol solution, shake it well, and react for 5 minutes; after the reaction, add 0.6 g potassium iodide, shake well, and place in the dark for 10 minutes to obtain the titration solution.

[0044] (3) titrate the solution to be titrated with a sodium thiosulfate solution with a concentration of 0.100mol / L, shake well while titrating, add 4 to 5 dr...

Embodiment 3

[0047] In this embodiment, the raw material to be tested—polyvinyl alcohol with a purity of 96% (degree of polymerization 2600, degree of alcoholysis 99.8%) is used to verify the accuracy of the method of the present invention. , the specific steps are as follows:

[0048] (1) Weigh 0.5098g of polyvinyl alcohol to be tested and add it to a conical beaker, then add 100mL of deionized water, heat up to 90°C, stir until completely dissolved, then cool to room temperature to obtain a polyvinyl alcohol solution.

[0049] (2) Add 6mL of 0.1000mol / L dilute hydrochloric acid and 0.0802g of sodium periodate (purity: 99.5%) to the polyvinyl alcohol solution, shake it well, and react for 5min; after the reaction, add 0.6 g potassium iodide, shake well, and place in the dark for 10 minutes to obtain the titration solution.

[0050] (3) titrate the solution to be titrated with a sodium thiosulfate solution with a concentration of 0.100mol / L, shake well while titrating, add 4 to 5 drops of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com