3D printing- and metal plating layer-base hollow pole wall waveguide slot array antenna

A metal coating and 3D printing technology, applied in slot antennas, antenna arrays that are powered on separately, antennas, etc., can solve the problems of difficult surface plating of devices and affect device performance, avoiding dielectric loss, frequency bandwidth, and widening matching bandwidth. and the effect of radiation bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

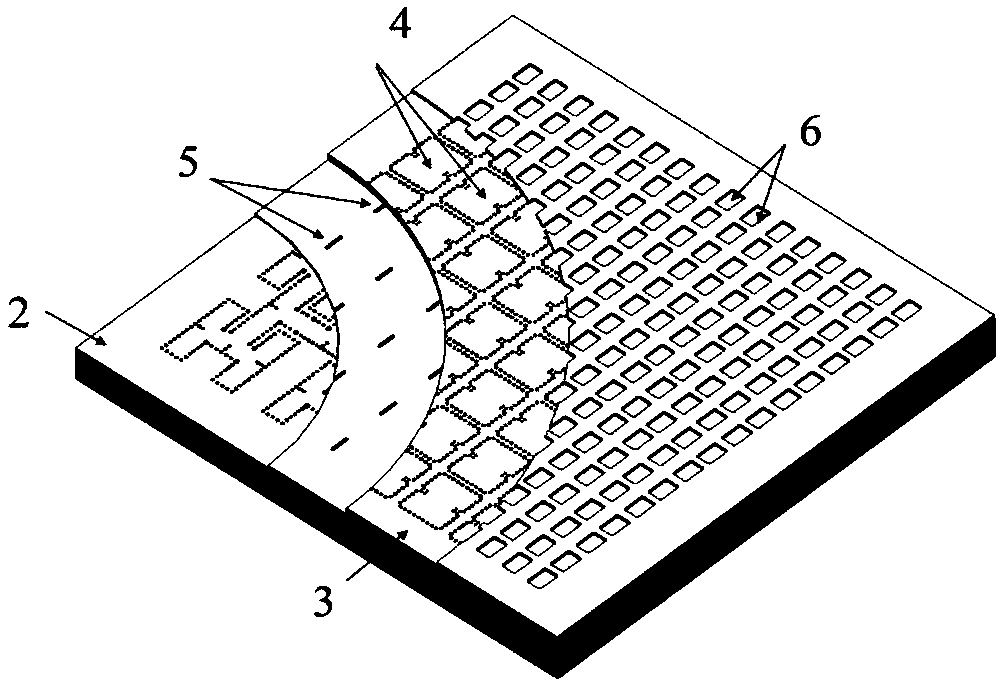

[0029] This embodiment is a hollow rod-wall waveguide slot array antenna based on 3D printing and metal coating. A 16×16 array element structure is selected, and a 2×2 array element structure is selected for the radiation sub-array. The array adopts a central back-fed feed with a center frequency of 61.5 GHz, and uses a fully parallel feed network to feed.

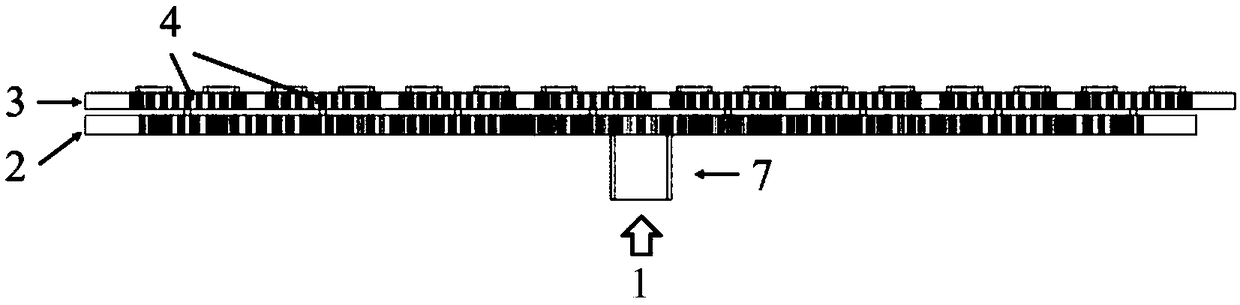

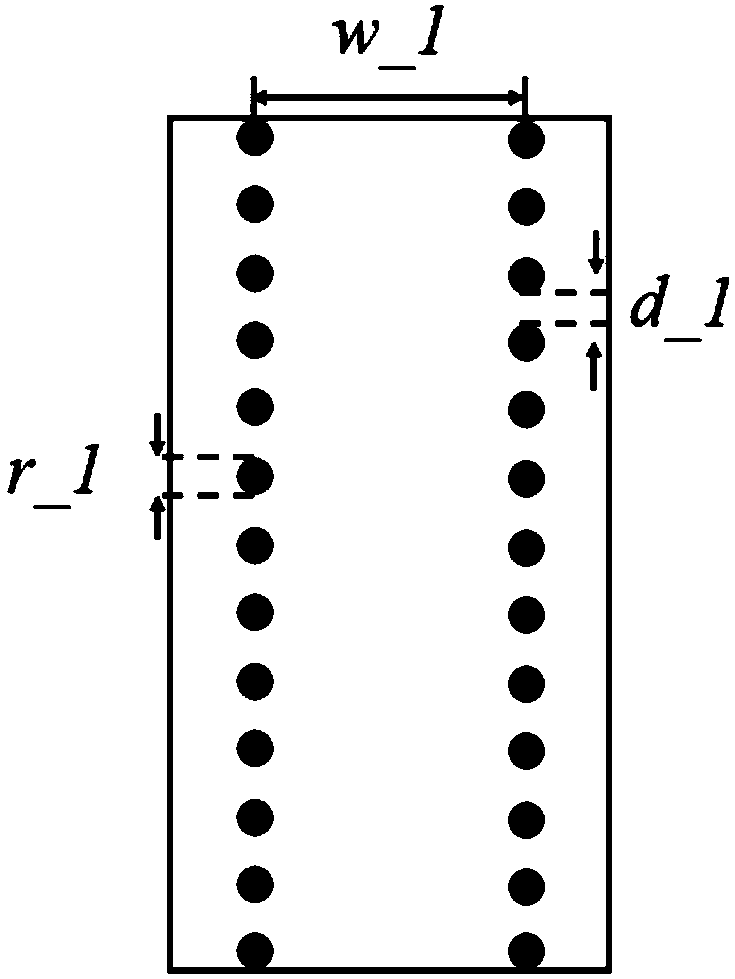

[0030] see figure 1 and 2 , the 16×16 antenna is composed of a metal-coated hollow rod-wall waveguide feeding network layer 2 and a metal-coated hollow rod-wall layer 3 containing a resonant cavity 4; the metal-coated hollow rod-wall waveguide feeding network layer 2 is integrated by a cascaded The feeding network composed of T and H-type power dividers, the input end 1 of the hollow rod-wall waveguide slot array antenna based on 3D printing and metal coating and the feeding network pass through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com