An intelligent control device for liquid nitrogen fine cooling of cold-rolled strip

A cold-rolled strip, liquid nitrogen technology, applied in metal rolling, metal rolling, temperature control and other directions, can solve the problem of friction coefficient, heat conduction law is no longer average, heat exchange efficiency is reduced, it is difficult to meet ultra-rapid cooling and parameters such as high-speed response, to achieve the effect of strengthening the cooling and lubrication effect of the roll gap and improving the copy rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

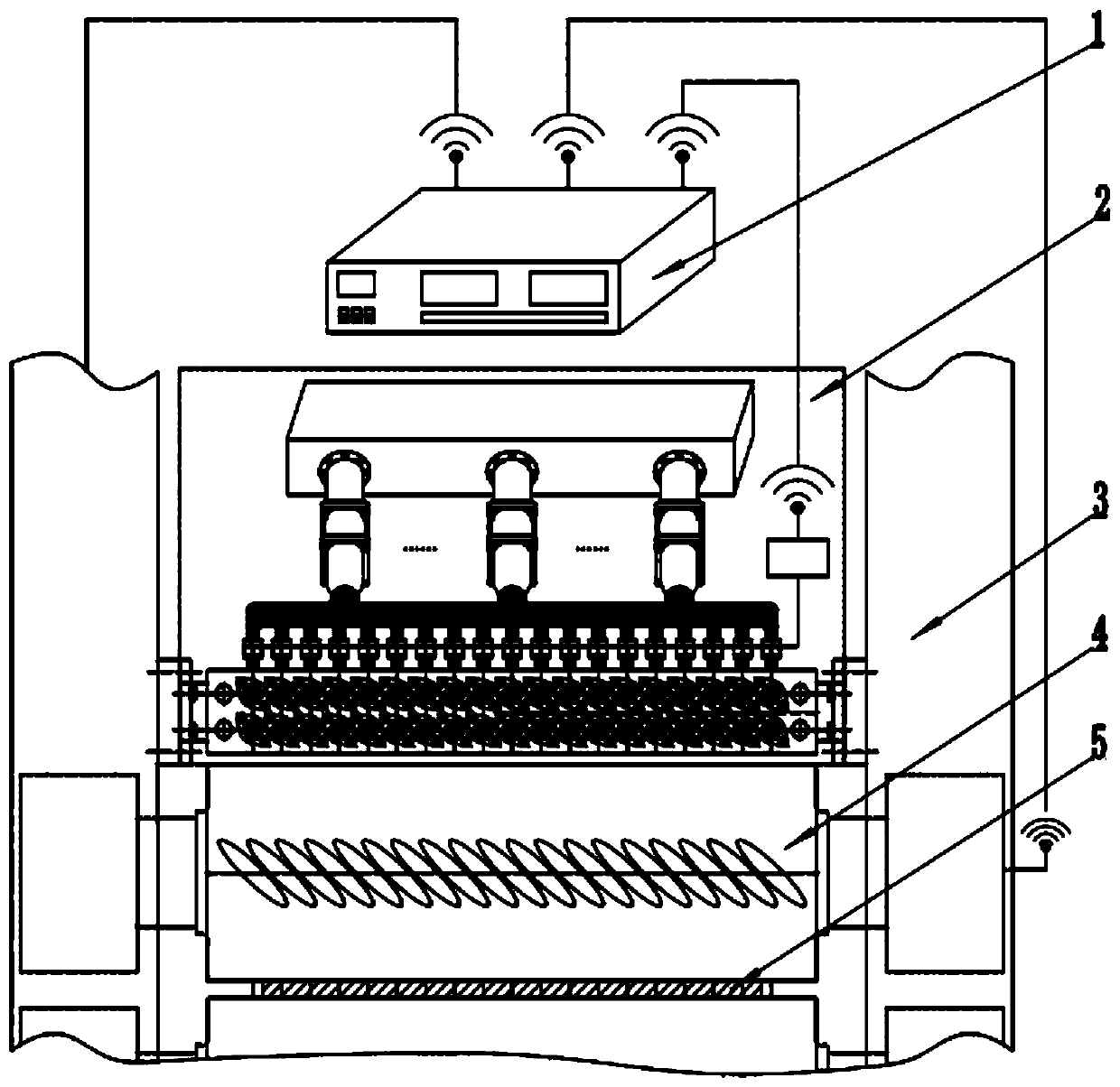

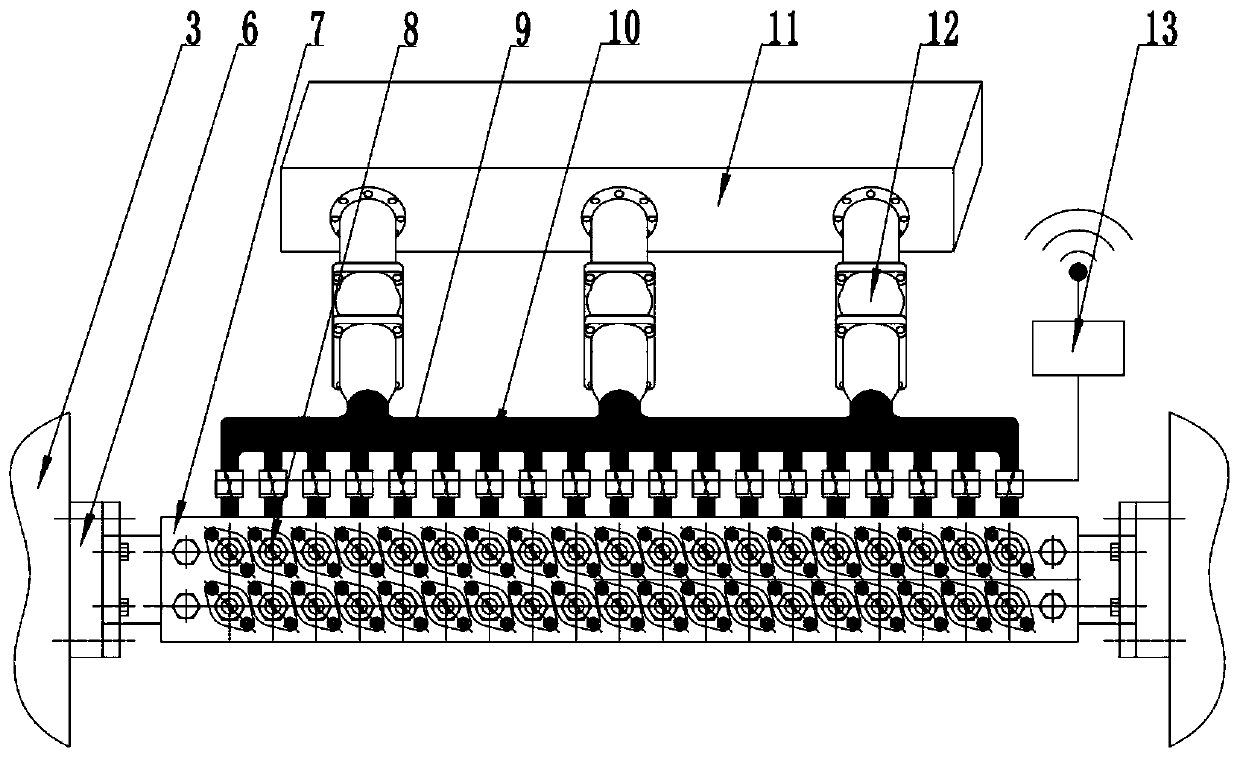

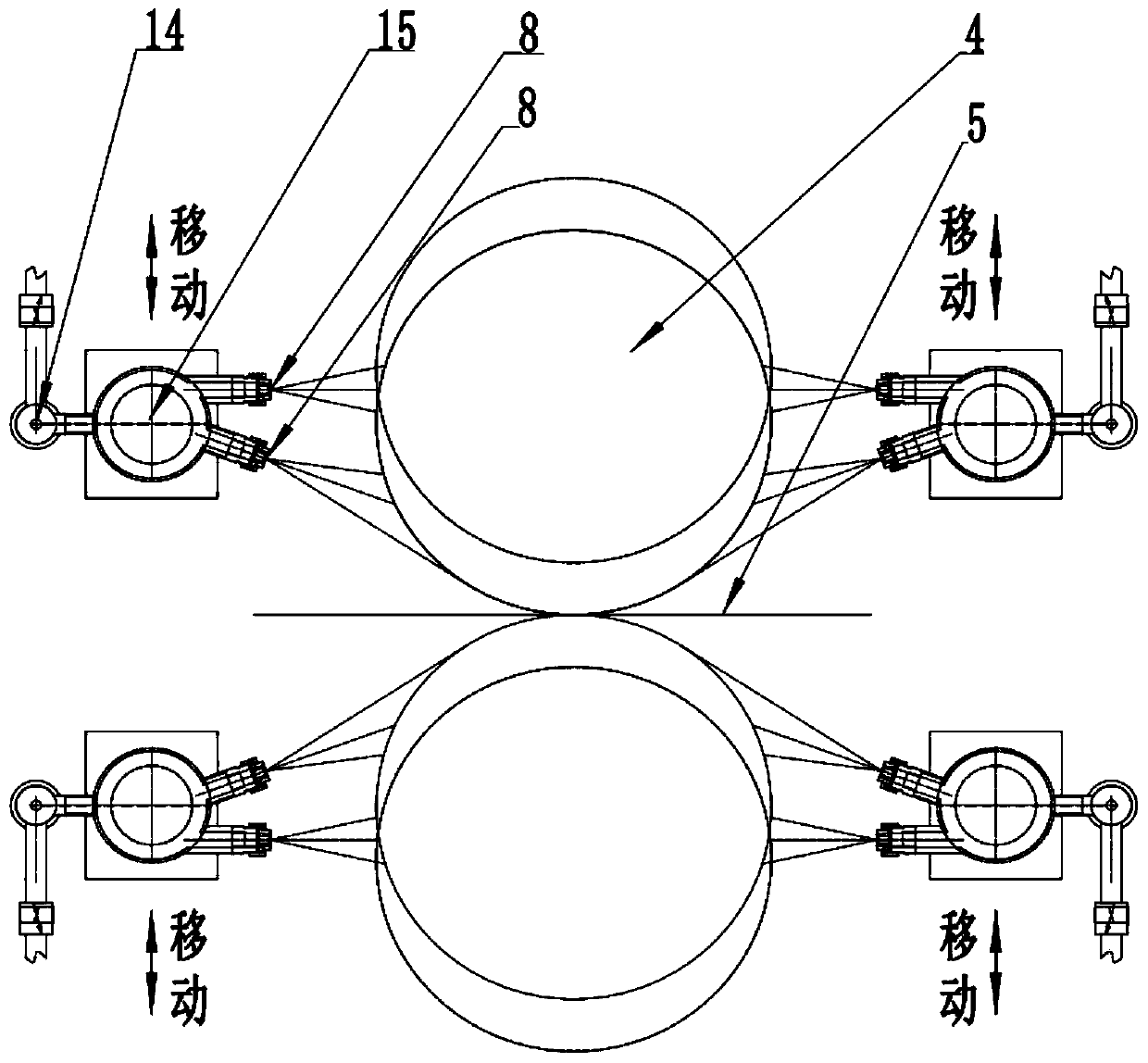

[0028] figure 1 The cold-rolled strip liquid nitrogen finishing cooling intelligent control device of an actual embodiment of the present invention includes: a wireless intelligent control system 1, a liquid nitrogen finishing cooling device 2 and a frame 3, wherein the liquid nitrogen finishing cooling device 2 is fixed on On the frame 3, the liquid nitrogen fine cooling device 2 communicates with the wireless intelligent control system 1 in real time through the first wireless transceiver 13 and immediately receives the control signal sequence sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com