Method for preparing cross-linked polyamide in body one-pot method

A technology of cross-linking polyamide and body, applied in the field of polyamide, can solve problems such as complicated preparation process, and achieve the effect of simple process and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

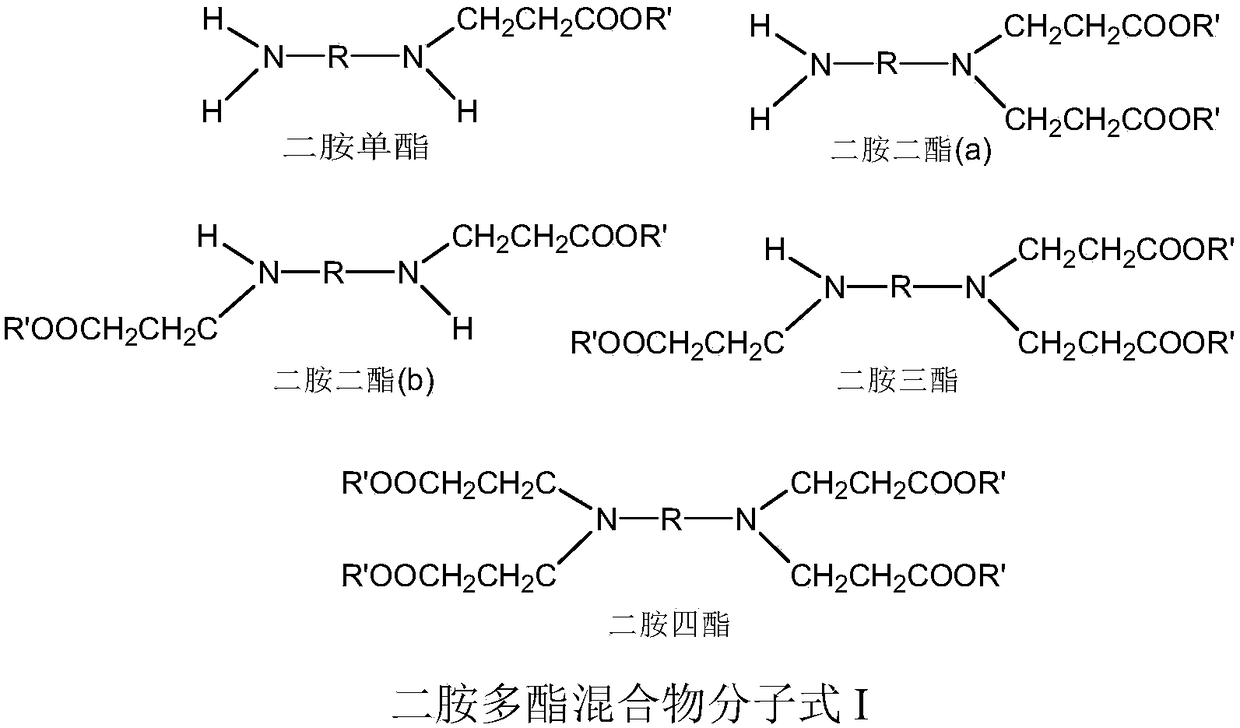

[0030] 1) Michael addition reaction: 116 parts of hexamethylenediamine and 344 parts of methyl acrylate were weighed by weight fraction, and reacted at 50°C for 3 hours to obtain a diamine polyester mixture.

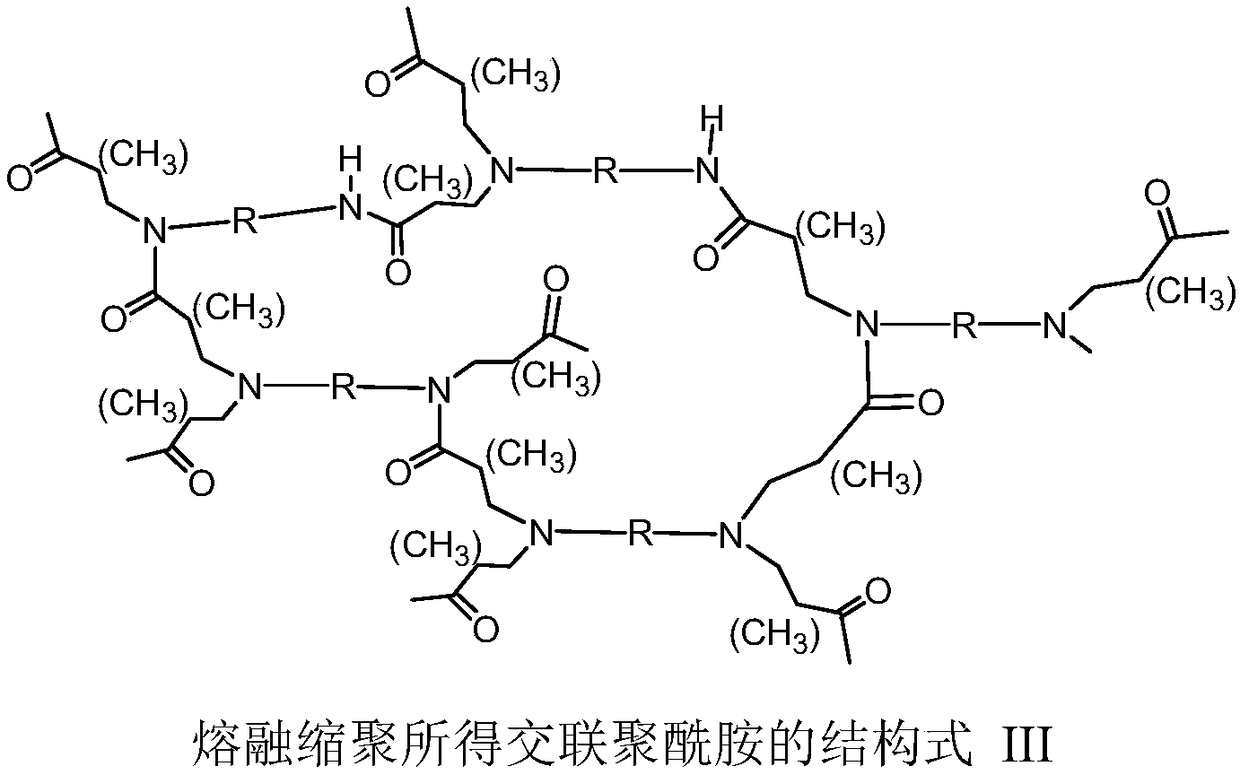

[0031] 2) Preparation of cross-linked polyamide: heat up the diamine polyester mixture obtained in step 1) to 170°C and react at normal pressure for 2 hours under the protection of nitrogen. -25mmHg) for 9 hours to obtain a cross-linked polyamide with a tensile strength of 38 MPa and an elongation at break of 25%.

Embodiment 2

[0033] 1) Michael addition reaction: 116 parts of hexamethylenediamine and 129 parts of methyl acrylate were weighed by weight fraction, and reacted at 50° C. for 3 hours to obtain a mixture of diamine polyesters.

[0034] 2) Preparation of cross-linked polyamide: heat up the diamine polyester mixture obtained in step 1) in Example 2 to 170°C and react under normal pressure for 40 minutes under nitrogen protection. React in a vacuum oven (25-30 mmHg) for 9 hours to obtain a cross-linked polyamide with a tensile strength of 45 MPa and an elongation at break of 21%.

Embodiment 3

[0036] 1) Michael addition reaction: 116 parts of hexamethylenediamine and 86 parts of methyl acrylate were weighed by weight fraction, and reacted at 60° C. for 3 hours to obtain a mixture of diamine polyesters.

[0037] 2) Preparation of cross-linked polyamide: heat up the diamine polyester mixture obtained in step 1) in Example 3 to 150°C and react under normal pressure for 20 minutes under nitrogen protection. React in a vacuum oven for 9 hours to obtain a cross-linked polyamide with a tensile strength of 3 MPa and an elongation at break of 69%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com