Engineering machinery bucket tooth induction heating structure repairing device and method

A technology of induction heating and tissue repair, applied in heat treatment furnaces, manufacturing tools, heat treatment equipment, etc., can solve the problems of difficult replacement, long working time, harsh working environment, etc., to ensure growth rate, ensure normal changes, and improve cooling efficiency. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

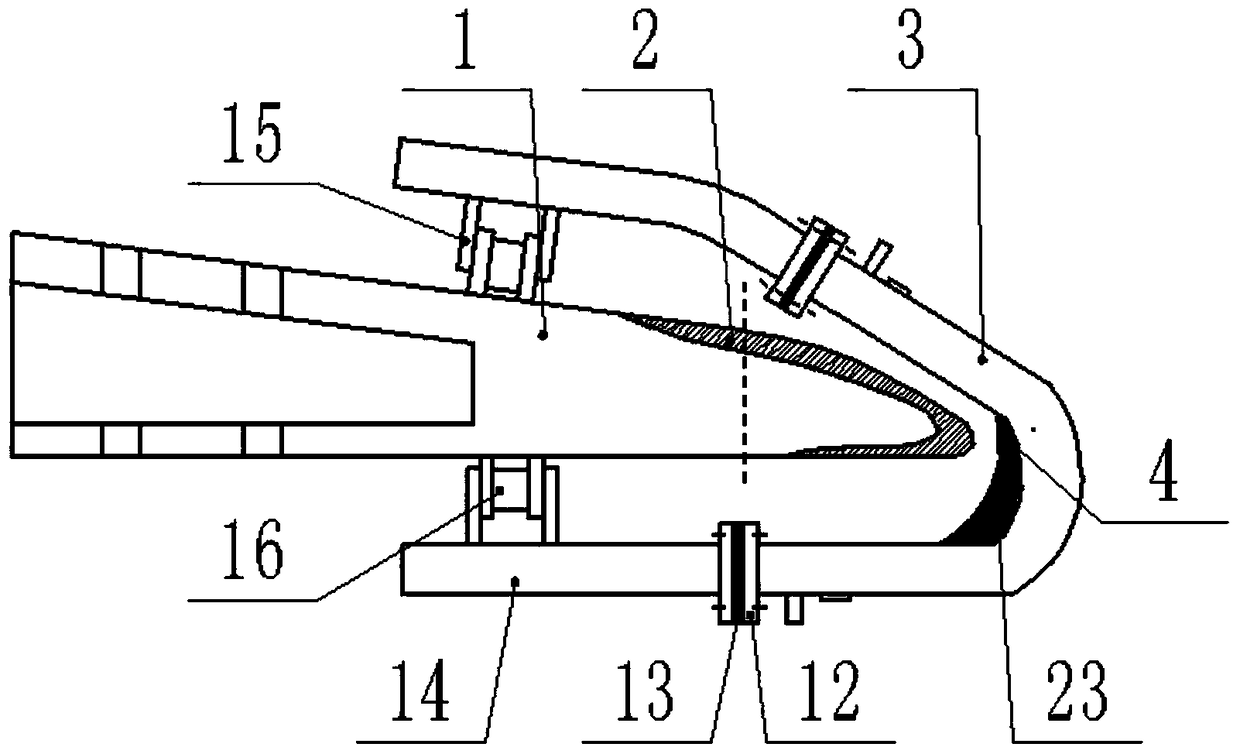

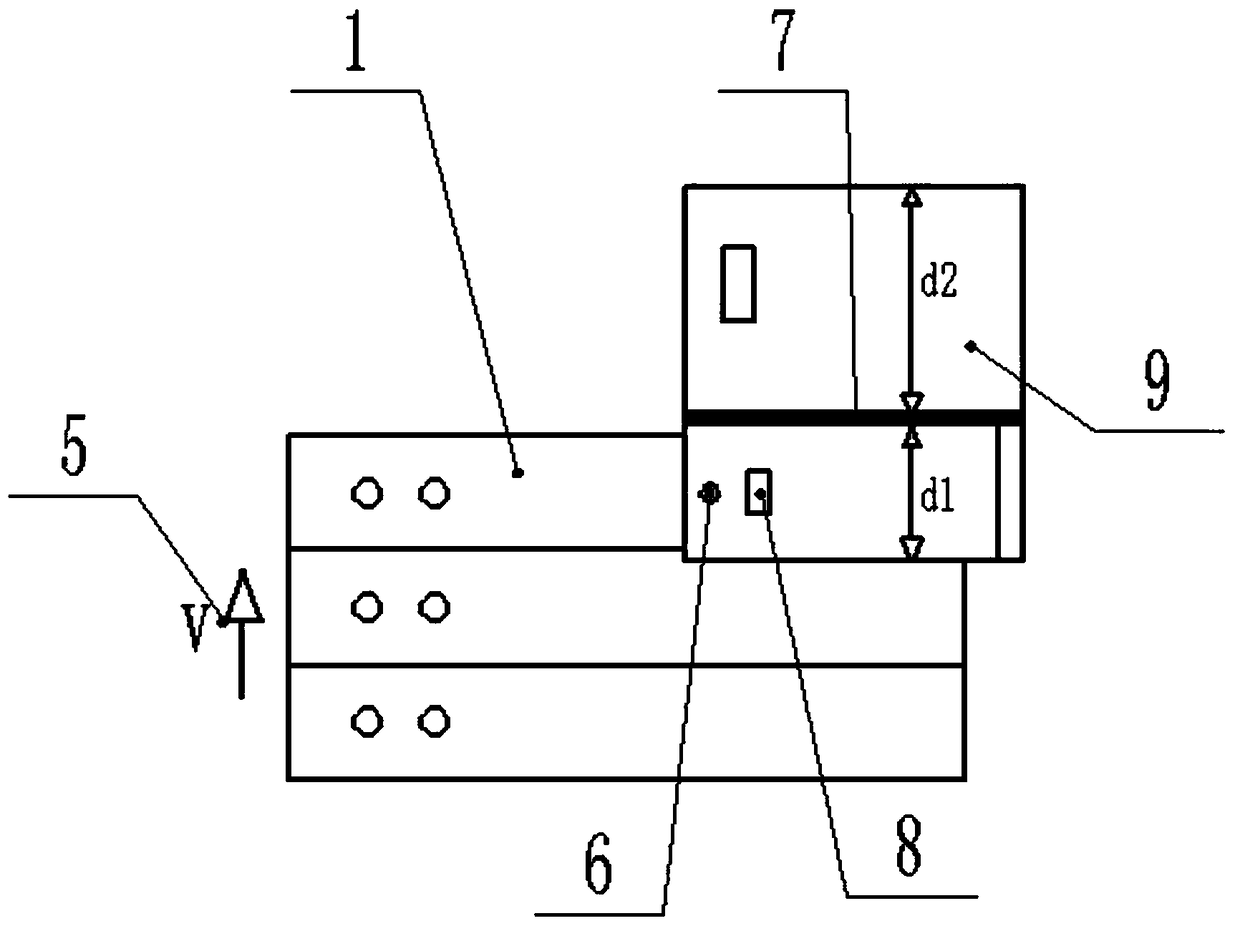

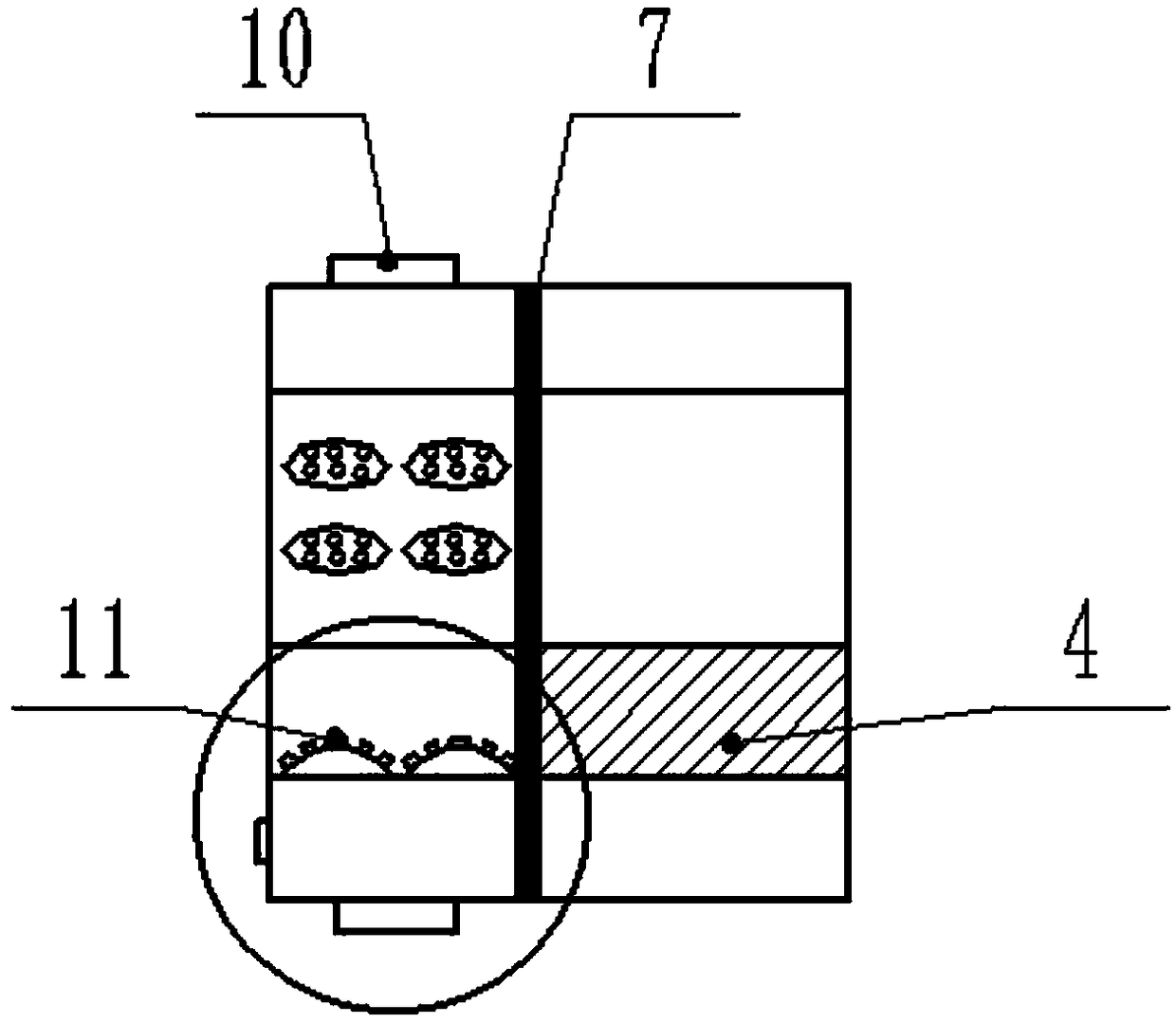

[0018] The present invention will be further described below in conjunction with accompanying drawing:

[0019] Such as Figure 1-4 As shown, the present invention mainly includes a bucket tooth 1, a folded coil 3, a water spray cooling chamber 9, and a pressurized ball 17. The folded coil 3 is in an open triangular shape, which is similar to the shape of the tip of the bucket tooth 1, and its inner wall is at a certain distance Bucket tooth 1 is placed in the position where the moving water moves. The bucket tooth 1 is arranged on the assembly line and passes through the folded coil 3 in turn, and then induction heating is carried out in turn. The assembly line moving direction of the bucket tooth 1 is along the bucket tooth processing direction 5. Corresponding to the included angle of the 3, a layer of tissue repair layer 2 is formed on the surface of the tip of the bucket tooth through induction heating of the folded coil 3, and a magnetizer 4 is fixedly installed inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com