Multi-element eutectic Al-Si alloy material and preparation method thereof

An alloy material, al-si technology, applied in the field of alloys, can solve the problems of limited application scope, reduced high temperature performance, reduced room temperature performance, etc., to achieve the effect of short solution and aging treatment time, and low comprehensive production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

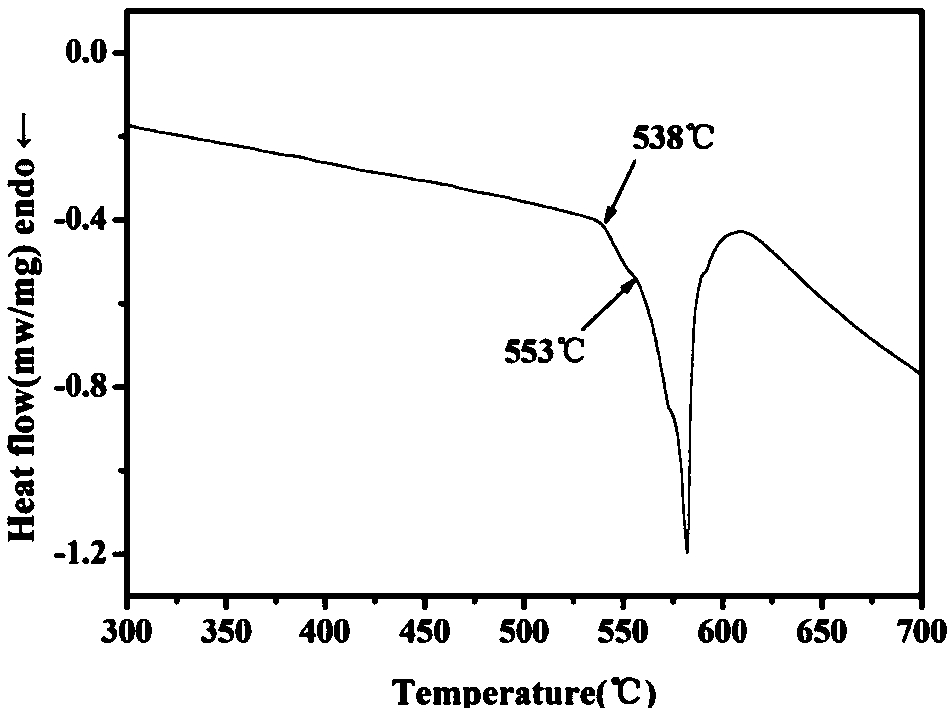

Method used

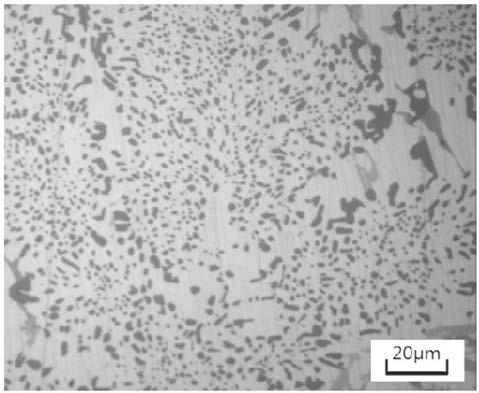

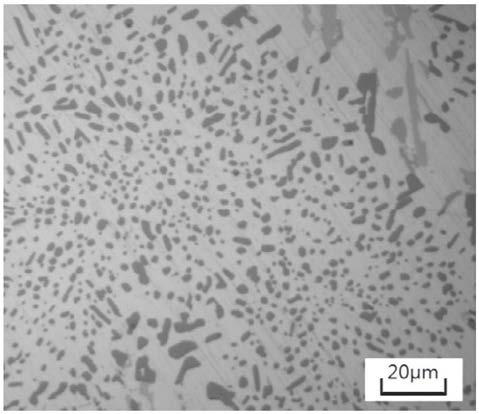

Image

Examples

Embodiment 1

[0039]A. Ingredients: Industrial pure aluminum is weighed according to the mass percentage of each element in the multi-component eutectic Al-Si alloy material: Al: 79.5%, Si: 13.0%, Cu: 4.5%, Mg: 1.0%, Ni: 2.0%. (99.99%), Al-20% Si master alloy (the mass of silicon accounts for 20% of the total mass of the master alloy), Al-50% Cu master alloy (the mass of copper accounts for 50% of the total mass of the master alloy), industrial pure magnesium (99.99%) and Al-10% Ni master alloy (the quality of nickel accounts for 10% of the total mass of the master alloy) for batching.

[0040] B. Melting: B1: Put industrial pure aluminum and Al-20% Si master alloy as the base material into the graphite clay crucible which has been preheated to 280°C, then put it into a well-type melting furnace and heat it to 770°C and keep it at a constant temperature. When the base material is softened and slumped, its surface is sprinkled with an amount of 0.6% covering agent (by 15wt% to 25wt% of CaO, ...

Embodiment 2

[0053] In this implementation, the T6 state multi-element eutectic Al-Si alloy material is prepared according to the method basically the same as that of Example 1, the only difference is:

[0054] In step A, industrial pure aluminum, Al-20% Si master alloy, Al -50% Cu master alloy, industrial pure magnesium and Al-10% Ni master alloy for batching;

[0055] The smelting temperature in steps B1, B2, B3 is respectively 780 ℃, 715 ℃ and 770 ℃, and the consumption of covering agent is respectively 0.5%, 0.6% and 0.6% of batching gross weight; In step B3, C 2 Cl 6 The dosage is 0.5% of the total weight of the ingredients. In step D, the alloy ingot is heated to 510°C.

[0056] The composition of the multi-element eutectic Al-Si alloy ingot obtained in step C was detected by an inductively coupled plasma atomic emission spectrometer, and the detection results are shown in Table 2. It can be seen from Table 2 that the smelting process adopted in this embodiment can produce alloy i...

Embodiment 3

[0061] In this implementation, the T6 state multi-element eutectic Al-Si alloy material is prepared according to the method basically the same as that of Example 1, the only difference is:

[0062] Step A weighs industrial pure aluminum, Al-20% Si master alloy, Al- 50% Cu master alloy, industrial pure magnesium and Al-10% Ni master alloy for batching;

[0063] The smelting temperatures in steps B1, B2, and B2 are respectively 790°C, 725°C, and 790°C, and the consumption of the covering agent is respectively 0.7%, 0.7%, and 0.5% of the total weight of the ingredients; in step B3, C 2 Cl 6 The dosage is 0.7% of the total weight of the ingredients. In step D, the alloy ingot is heated to 520°C.

[0064] The composition of the multi-element eutectic Al-Si alloy ingot obtained in step C was detected by an inductively coupled plasma atomic emission spectrometer, and the detection results are shown in Table 3. It can be seen from Table 3 that the smelting process adopted in this e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com