Cleaning device and technology for low-temperature methanol washing feed gas precooler

A technology of gas pre-cooler and low-temperature methanol washing, which is applied in the direction of cleaning heat transfer devices, flushing, lighting and heating equipment, etc., can solve problems such as clogging of crude gas pre-coolers, reduce water consumption costs, achieve zero emissions, Good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

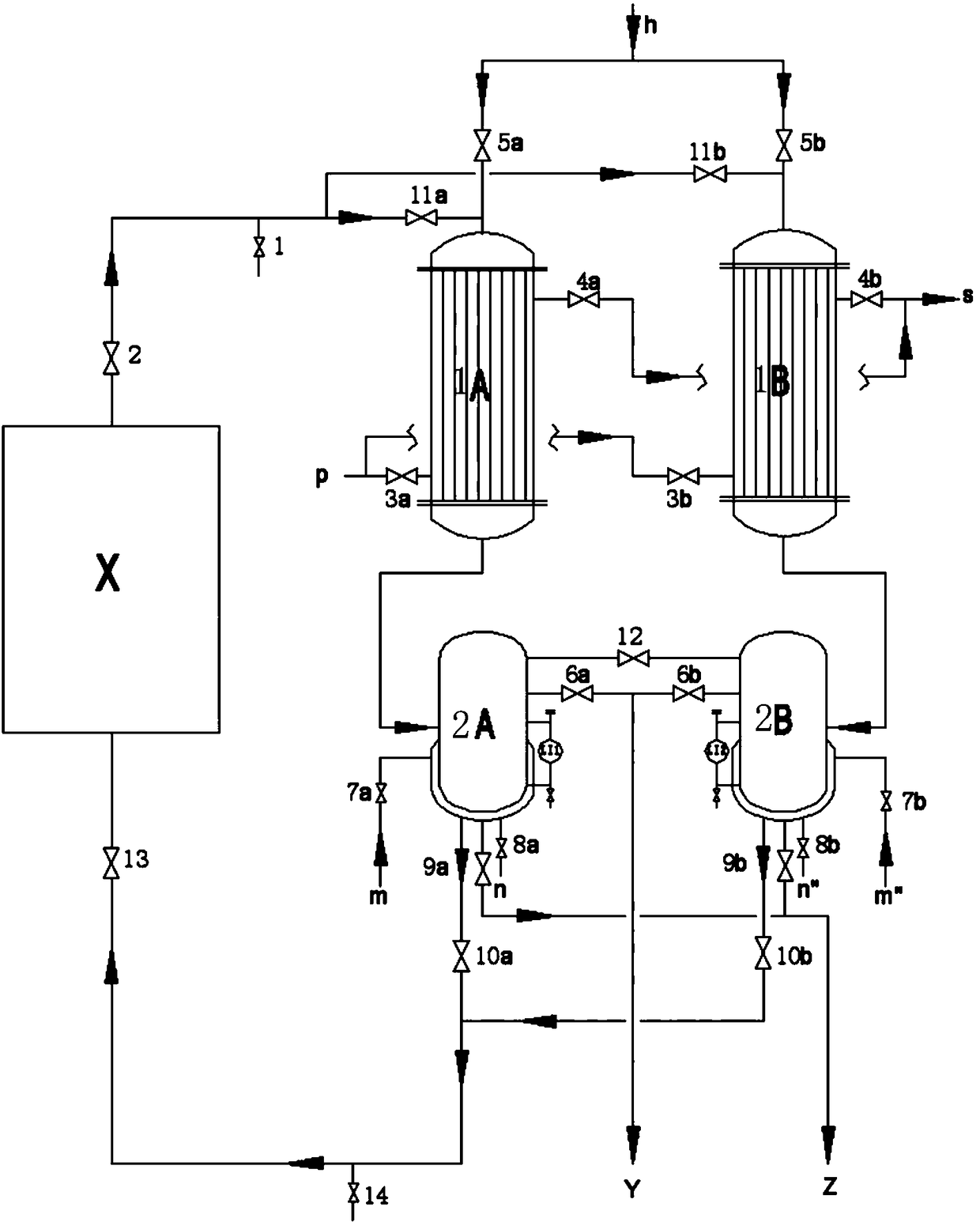

[0044] Such as figure 1 The shown low-temperature methanol washing feed gas precooler cleaning device includes: cleaning gas water treatment process device X, crude gas precooler 1A open / 1B standby, gas-liquid separator 2A open / 2B standby; cleaning gas water treatment process The device X is equipped with a washing water outlet and a washing water return port, which are used to provide high-temperature, high-pressure circulating gas water for cleaning; the crude gas precooler, 1A is opened and 1B is prepared, and each crude gas precooler is equipped with a washing The water inlet, the crude gas inlet, the cold medium inlet, the cold medium outlet, and the liquid outlet; the washing water inlet communicates with the washing water outlet of the washing gas water treatment process device X through the washing water inlet pipe, and The main washing water inlet valve 2, the pressure relief valve 1, and the washing water inlet valve 11a / 11b for controlling the flow of washing water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com