Method for preparing photocatalytic filter membrane by electrospinning

An electrospinning and photocatalytic technology, applied in the field of membrane materials, can solve problems such as threats to health, secondary pollution, and inability to completely control pollutants, avoid the use of pore-forming agents, and reduce the steps of membrane-making. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method for preparing a photocatalytic filter membrane by electrospinning, comprising the following preparation steps:

[0020] S1, 2 parts by weight of aniline, 1 part of nano-titanium dioxide and 50 parts of polyacrylonitrile were dissolved in dimethylacetamide at 20 ° C to obtain a mixed solution;

[0021] S2. Using electrospinning technology to spin the mixed solution to prepare a porous membrane, soak the porous membrane in a hydrochloric acid solution with a concentration of 1 mole per liter at 0-5°C for 24 hours, take it out, wash it with water, and dry it to obtain a photocatalytic filter membrane. .

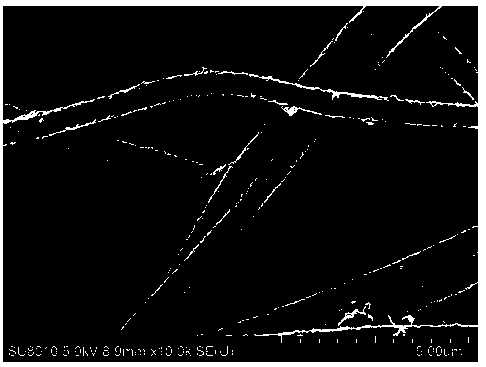

[0022] Electrospinning in embodiment 1 prepares the scanning electron microscope picture of photocatalytic filter membrane figure 1 As shown, it can be seen that a porous filter membrane with a pore size of 1-10 microns was prepared by electrospinning technology.

Embodiment 2

[0024] A preparation method for preparing a photocatalytic filter membrane by electrospinning, comprising the following preparation steps:

[0025] S1. Dissolving 6 parts of aniline, 3 parts of nano-titanium dioxide and 98 parts of polyvinyl chloride into dimethylformamide at 80°C to obtain a mixed solution;

[0026] S2. Using electrospinning technology to spin the mixed solution to prepare a porous membrane, soak the porous membrane in a hydrochloric acid solution with a concentration of 1 mole per liter at 0-5°C for 24 hours, take it out, wash it with water, and dry it to obtain a photocatalytic filter membrane. .

Embodiment 3

[0028] A preparation method for preparing a photocatalytic filter membrane by electrospinning, comprising the following preparation steps:

[0029] S1. Dissolve 4 parts of aniline, 2 parts of nano-titanium dioxide and 70 parts of polyvinyl chloride and polyacrylonitrile (the mass ratio of polyvinyl chloride and polyacrylonitrile is 1:1) in dimethyl sulfoxide at 50°C, to obtain a mixed solution;

[0030] S2. Using electrospinning technology to spin the mixed solution to prepare a porous membrane, soak the porous membrane in a hydrochloric acid solution with a concentration of 1 mole per liter at 0-5°C for 24 hours, take it out, wash it with water, and dry it to obtain a photocatalytic filter membrane. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com