A kind of humic acid modified nano Fe 2 o 3 Material preparation method and application of removing estradiol

A humic acid and fe2o3 technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problems of high cost, secondary pollution, cumbersome steps, etc., and achieve a large specific surface area , high removal efficiency, fast and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

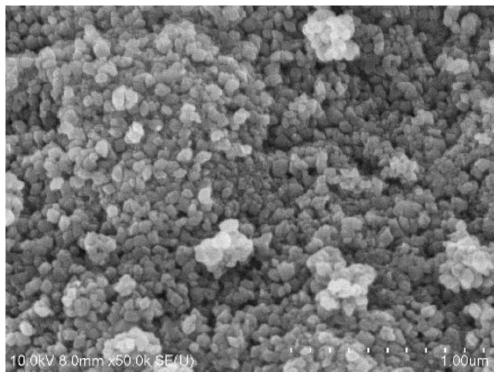

[0019] Humic acid modified nano-Fe 2 O 3 The specific preparation method of the material is as follows:

[0020] (1) Weigh 40g of Fe(NO 3 ) 3 ·9H 2 Dissolve O in 500mL deionized water preheated to 90℃, add 300mL of 1mol / L KOH solution preheated to 90℃, and add 50mL of 1 mol / L NaHCO preheated to 90℃ 3 , Keep in a water bath at 90℃ for 48h with a lid.

[0021] (2) Pour the supernatant, precipitate and separate, remove excess OH - And NO 3 - ,dry.

[0022] (3) Weigh 25g of the obtained solid and place it in a beaker, add 500mL of humic acid solution and mix with a solid-to-liquid ratio of 1:20. Use 0.1mol / L NaOH solution or HCl solution to adjust the pH to 8.0, Shake at a constant temperature of 25°C for 48h, and then centrifuge at 4000r / min for 15min.

[0023] (4) Pour the supernatant liquid, centrifuge and rinse the solid repeatedly with deionized water until the organic carbon concentration in the supernatant liquid no longer changes significantly, freeze-dry the solid at -45°C for 48...

Embodiment 2

[0026] The humic acid modified nano-Fe prepared in Example 1 2 O 3 The material is used to remove 17β-estradiol, the specific method is as follows:

[0027] (1) Prepare a 17β-estradiol solution with a concentration gradient of 0.025-1 mg / L.

[0028] (2) Weigh 0.05g of humic acid modified nano Fe 2 O 3 Put the materials into a brown glass bottle, add 10 mL of the above-mentioned 17β-estradiol solutions of different concentrations, and shake at a constant temperature for 48 hours at 25°C.

[0029] (3) After the adsorption equilibrium, take the suspension and centrifuge, pass the 0.22μm glass filter membrane and add it to a 1mL sample bottle, and use LC-MS to determine the concentration of the solution after the reaction. The results are shown in Table 1:

[0030] Table 1: Adsorption capacity under different initial conditions of 17β-estradiol

[0031] Initial concentration (mg / L) Adsorption capacity (mg / kg) 123.26 0.621.89 0.417.61 0.210.58 0.15.98 0.051.73 0.0251.13

[0032] It can...

Embodiment 3

[0034] The humic acid modified nano-Fe prepared in Example 1 2 O 3 The material is used to remove 17β-estradiol, the specific method is as follows:

[0035] (1) Weigh 0.05g of humic acid modified nano Fe 2 O 3 Materials As for the conical flask, add 100 mL of 0.1 mg / L 17β-estradiol solution and shake at a constant temperature of 25°C for 48 hours.

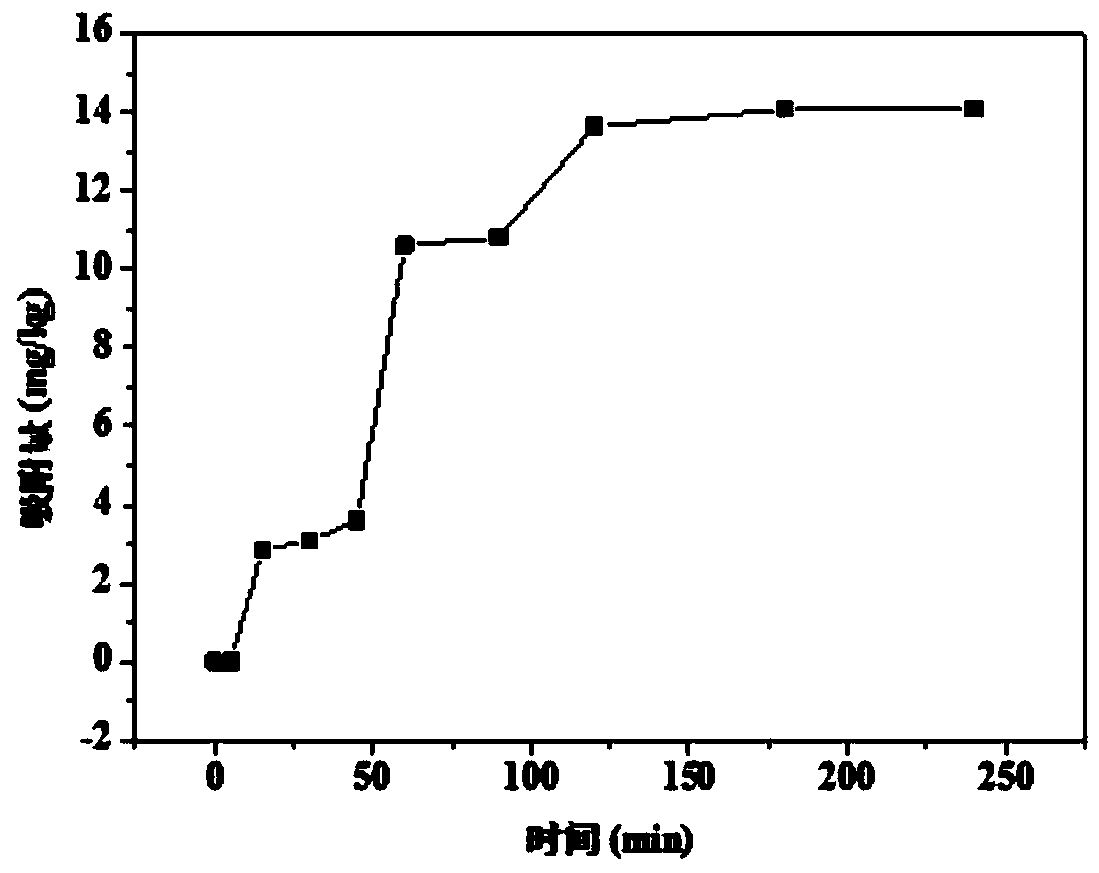

[0036] (2) Centrifuge the suspension at different intervals of 0-250min, then add it to a 1mL sample bottle after passing through a 0.22μm glass filter membrane, and measure the concentration of the solution after the reaction by LC-MS.

[0037] The adsorption capacity results at different times are as follows figure 2 Shown by figure 2 It can be seen that the humic acid modified nano-Fe 2 O 3 The adsorption capacity of the material on 17β-estradiol increased with time. Between 0-120min, the adsorption capacity increased rapidly and gradually reached saturation after 120min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com