Thermal-insulating anti-scouring heat shielding layer and preparation method thereof

A heat-resistant layer and anti-scour technology, applied in chemical instruments and methods, layered products, metal layered products, etc. Key technologies and other issues to achieve the effect of increasing the effective flight load and reducing the important

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

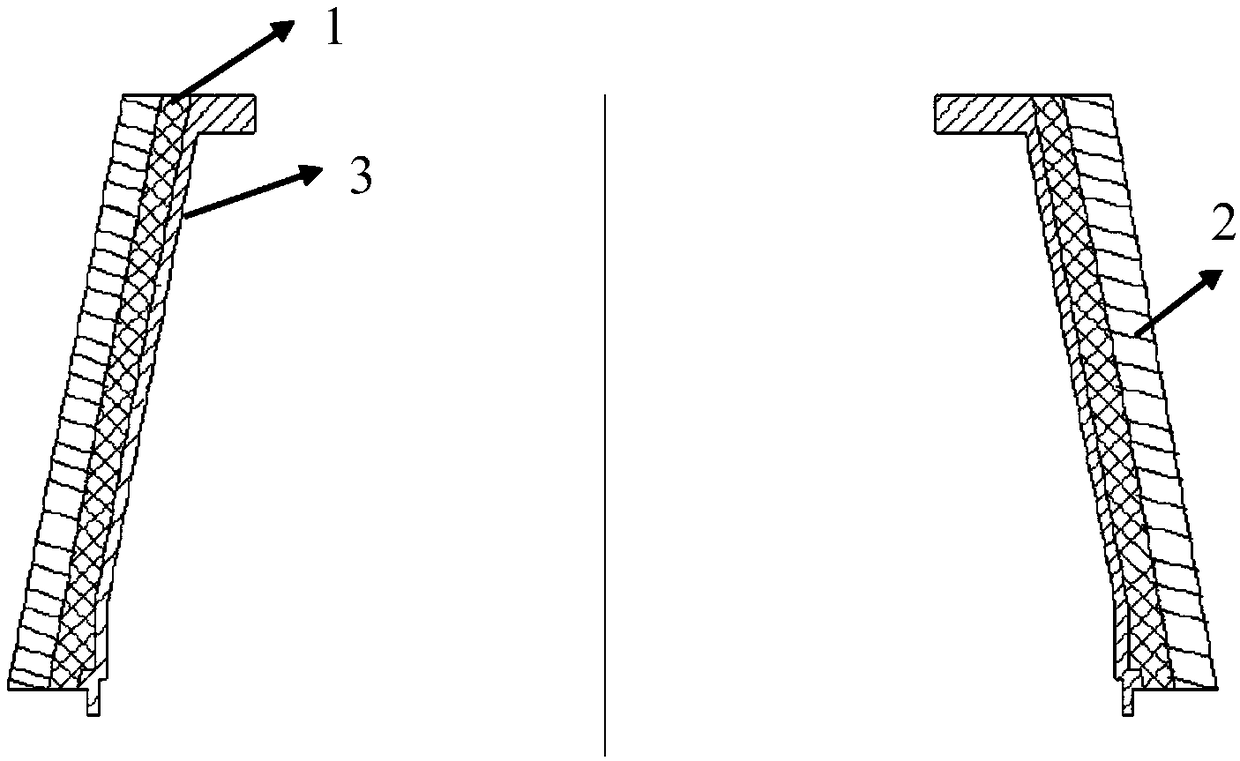

[0092] Embodiment 1 provides a heat-insulating, anti-scour and heat-proof layer, the heat-proof layer includes an inner layer of heat-insulating layer and an outer layer of anti-scour and heat-proof layer;

[0093] The inner heat insulation layer is made of modified phenolic resin solution and fiber prefabricated body through sol-gel reaction, aging and drying;

[0094] The outer scour-resistant and heat-proof layer is made of ablation-resistant resin solution and ablation-resistant fiber fabric through winding molding.

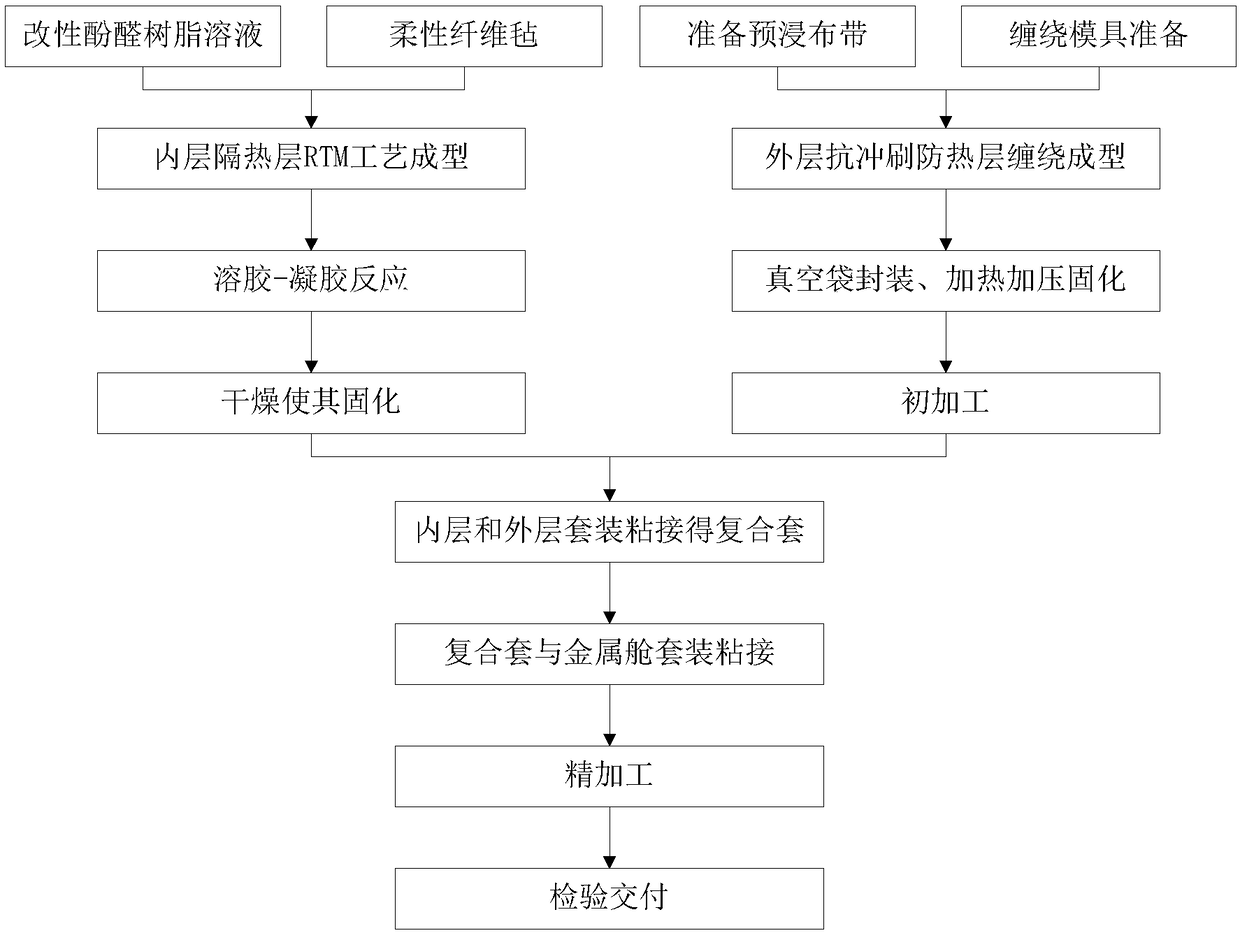

[0095] Such as figure 1 As shown, the specific preparation steps are as follows:

[0096] (a) Preparation of inner heat insulation layer

[0097] (1) Mix the modified phenolic resin, curing agent and solvent evenly, dissolve completely and prepare the modified phenolic resin solution; wherein, the modified phenolic resin is selected from boron modified phenolic resin, and the curing agent is selected from hexamethylene tetra Amine, solvent selects ethano...

Embodiment 2

[0113] Embodiment 2 provides a heat-insulating, anti-scour and heat-proof layer, the heat-proof layer includes an inner layer of heat-insulating layer and an outer layer of anti-scour and heat-proof layer;

[0114] The inner heat insulation layer is made of modified phenolic resin solution and fiber prefabricated body through sol-gel reaction, aging and drying;

[0115] The outer scour-resistant and heat-proof layer is made of ablation-resistant resin solution and ablation-resistant fiber fabric through winding molding.

[0116] Concrete preparation steps are as follows:

[0117] (a) Prepare the outer anti-scour and heat-resistant layer

[0118] The preparation method is basically the same as that of Example 1, except that the width of the outer prepreg tape is 25 mm, and the winding thickness is 3 mm.

[0119] (b) Integral molding

[0120] Trial assembly: Pre-assemble the fiber prefabricated body in the outer anti-scouring heat-proof layer and the inner heat insulation...

Embodiment 3

[0127] Embodiment 3 provides a heat-insulating, anti-scour and heat-proof layer, the heat-proof layer includes an inner layer of heat-insulating layer and an outer layer of anti-scour and heat-proof layer;

[0128] The inner heat insulation layer is made of modified phenolic resin solution and fiber prefabricated body through sol-gel reaction, aging and drying;

[0129] The outer scour-resistant and heat-proof layer is made of ablation-resistant resin solution and ablation-resistant fiber fabric through winding molding.

[0130] Preparation method is basically the same as Example 1, except that:

[0131] In step (a), the curing agent is selected from paraformaldehyde, and the mass ratio of boron modified phenolic resin and paraformaldehyde is 20:1;

[0132] In step (b), the ablation-resistant fiber fabric is selected from viscose-based carbon fiber plain cloth; the winding angle is 20°, the pressure is 0.3MPa, the temperature is 80°C, the tape preheating temperature is 70°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com