Water-based epoxy emulsion capable of dissolving and reacting with oil-based curing agent and preparation method thereof

A water-based epoxy emulsion and curing agent technology, applied in the field of epoxy emulsion preparation, can solve problems such as poor performance, poor compatibility, incomplete reaction, etc., and achieve good compatibility, high catalytic activity, and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

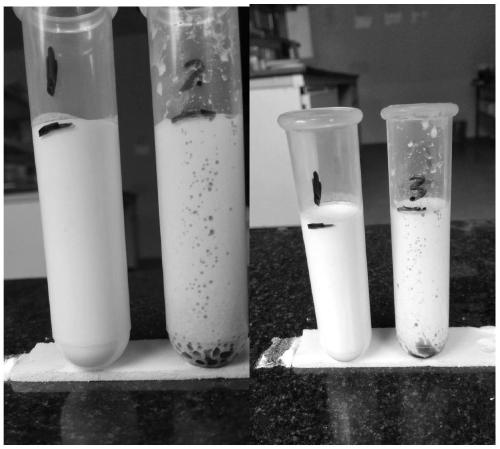

Image

Examples

Embodiment 1

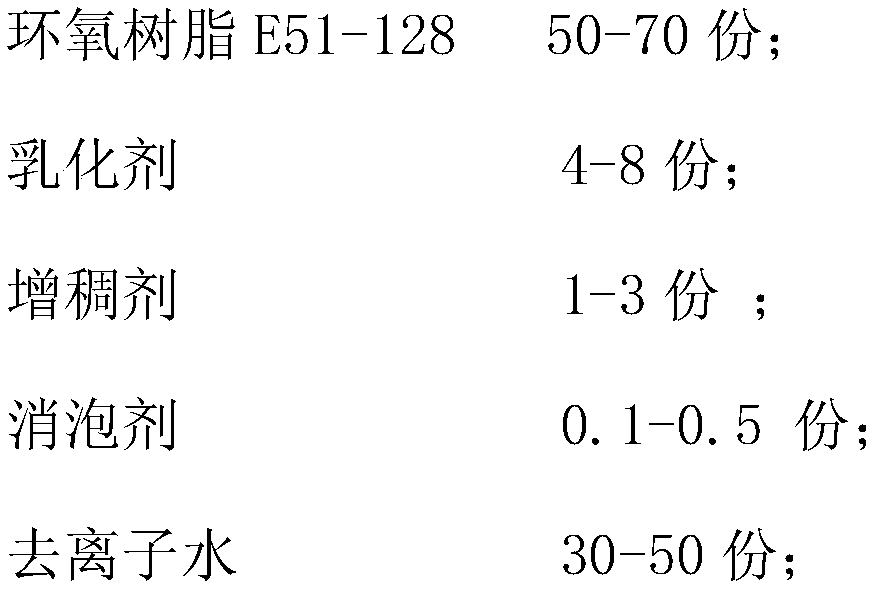

[0032] A kind of water-based epoxy emulsion capable of miscible reaction with oil curing agent, in parts by weight, comprises the following components:

[0033]

[0034] The emulsifier is a mixture of reactive emulsifiers and other types of emulsifiers, the mass ratio of the two is 3:1.5; the reactive emulsifier is a modified fatty alcohol polyoxyethylene emulsifier;

[0035] The preparation method of this aqueous epoxy emulsion comprises the following steps:

[0036] (1) Mix hydroxyapatite and cyclohexane, then add stearyloxyisopropyl aluminate, add triethylamine dropwise, slowly heat up to 100°C, and reflux for 1 hour; after the reaction is completed, cool to room temperature, Then add ethyl orthosilicate dropwise to the reaction system, raise the temperature to 130°C, continue to reflux for 5 hours, cool to room temperature after the reaction, filter, wash the precipitate with deionized water and absolute ethanol in turn, and dry to obtain the modified Nano silicon oxid...

Embodiment 2

[0041] A kind of water-based epoxy emulsion capable of miscible reaction with oil curing agent, in parts by weight, comprises the following components:

[0042]

[0043] The emulsifier is a mixture of reactive emulsifiers and other types of emulsifiers, the mass ratio of the two is 4.5:2; the reactive emulsifier is a modified fatty alcohol polyoxyethylene emulsifier;

[0044] The preparation method of this aqueous epoxy emulsion comprises the following steps:

[0045] (1) Mix hydroxyapatite and cyclohexane, then add stearyloxyisopropyl aluminate, add triethylamine dropwise, slowly heat up to 120°C, and reflux for 5 hours; after the reaction is completed, cool to room temperature, Then add ethyl orthosilicate dropwise to the reaction system, raise the temperature to 150°C, continue to reflux for 10 hours, cool to room temperature after the reaction, filter, wash the precipitate with deionized water and absolute ethanol in turn, and dry to obtain the modified Nano silicon ox...

Embodiment 3

[0050] A kind of water-based epoxy emulsion capable of miscible reaction with oil curing agent, in parts by weight, comprises the following components:

[0051]

[0052] The emulsifier is a mixture of reactive emulsifiers and other types of emulsifiers, the mass ratio of the two is 3:1.5; the reactive emulsifier is a modified fatty alcohol polyoxyethylene emulsifier;

[0053] The preparation method of this aqueous epoxy emulsion comprises the following steps:

[0054] (1) Mix hydroxyapatite and cyclohexane, then add stearyloxyisopropyl aluminate, add triethylamine dropwise, slowly heat up to 105°C, and reflux for 2 hours; after the reaction, cool to room temperature, Then add ethyl orthosilicate dropwise to the reaction system, raise the temperature to 135°C, continue to reflux for 6 hours, cool to room temperature after the reaction, filter, wash the precipitate with deionized water and absolute ethanol in turn, and dry to obtain the modified Nano silicon oxide / hydroxyapa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com