Quick-drying printing ink for soft PVC and preparation method

A fast-drying, soft technology, applied in the field of printing graphite, can solve the problems of unwillingness of printing manufacturers to use, short production time, slow drying speed, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

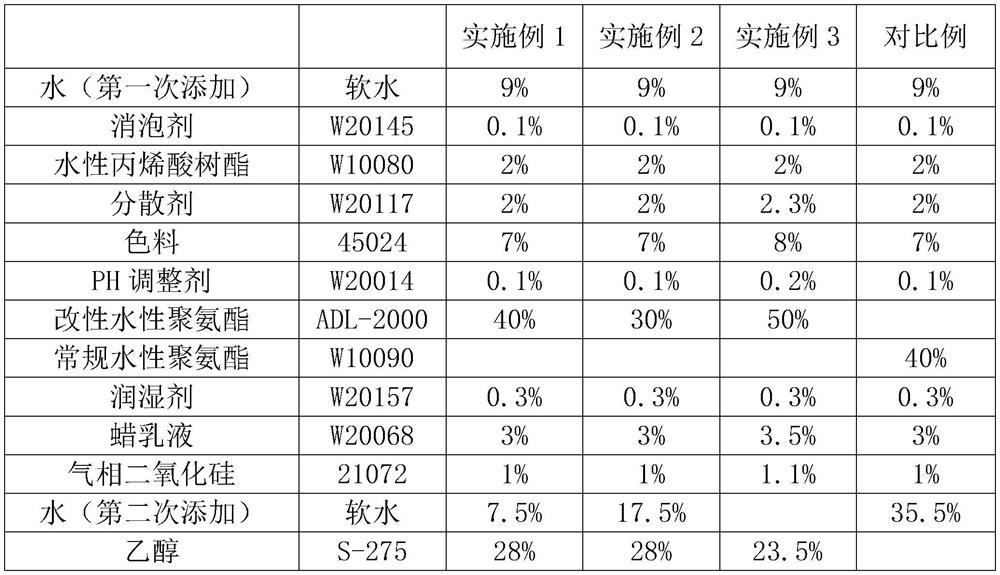

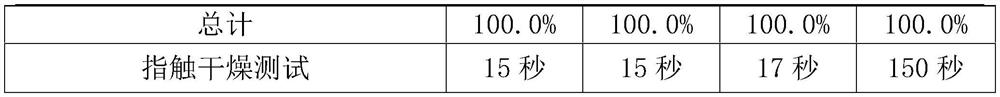

Embodiment 1

[0021] A quick-drying printing ink for soft PVC, comprising: 40% modified water-based polyurethane resin, 2% water-based acrylic resin, 16.5% water, 0.3% wetting agent, 7% colorant, Dispersant 2%, defoamer 0.1%, pH adjuster 0.1%, wax emulsion 3%, anti-sedimentation powder 1% and ethanol 28%, the sum of each component content is 100%.

[0022] A preparation method for quick-dry printing ink for soft PVC, comprising the following preparation steps:

[0023] In the first step, add 0.1% defoamer, 2% water-based acrylic resin, 2% dispersant, 7% colorant, 0.1% PH regulator and 9% water to the high-efficiency grinder for grinding Disperse for at least 120 minutes; wherein the grinding power is preferably 10KW, and the grinding speed is set at 800rpm.

[0024] In the second step, the mixed material obtained in the first step is transferred to the mixer;

[0025] In the third step, continue to add 40% of modified water-based polyurethane resin, 0.3% of wetting agent, 3% of wax emulsi...

Embodiment 2

[0036] A quick-drying printing ink for soft PVC, comprising: 30% modified water-based polyurethane resin, 2% water-based acrylic resin, 26.5% water, 0.3% wetting agent, 7% colorant, Dispersant 2%, defoamer 0.1%, pH adjuster 0.1%, wax emulsion 3%, anti-sedimentation powder 1% and ethanol 28%, the sum of each component content is 100%.

[0037] The source of each component involved in this embodiment is the same as that in Example 1.

[0038] A preparation method for quick-dry printing ink for soft PVC, comprising the following preparation steps:

[0039] In the first step, add 0.1% defoamer, 2% water-based acrylic resin, 2% dispersant, 7% colorant, 0.1% PH regulator and 9% water to the high-efficiency grinder for grinding Disperse for at least 120 minutes; the grinding power is preferably 11KW, and the grinding speed is set at 700rpm.

[0040] In the second step, the mixed material obtained in the first step is transferred to the mixer;

[0041] In the third step, continue t...

Embodiment 3

[0043] A quick-drying printing ink for soft PVC, comprising: 50% modified water-based polyurethane resin, 2% water-based acrylic resin, 9% water, 0.3% wetting agent, 8% colorant, Dispersant 2.3%, defoamer 0.1%, pH adjuster 0.2%, wax emulsion 3.5%, anti-sedimentation powder 1.1% and ethanol 23.5%, the sum of each component content is 100%.

[0044] The source of each component involved in this embodiment is the same as that in Example 1.

[0045] A preparation method for quick-dry printing ink for soft PVC, comprising the following preparation steps:

[0046] In the first step, add 0.1% defoamer, 2% water-based acrylic resin, 2.3% dispersant, 8% colorant, 0.2% PH regulator and 9% water to the high-efficiency grinder for grinding Disperse for at least 120 minutes; the grinding power is preferably 12KW, and the grinding speed is set at 600rpm.

[0047] In the second step, the mixed material obtained in the first step is transferred to the mixer;

[0048]In the third step, cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com