High-paraffin high-temperature high-salinity oil well microorganism paraffin removing and inhibiting agent and preparation method thereof

A microbial, paraffin-removing technology, applied in chemical instruments and methods, cleaning equipment, earth drilling and mining, etc., can solve the problem of high temperature of microorganism paraffin-removing bacteria, poor wax-removing effect, high salinity and low tolerance and other issues, to achieve the effect of low cost, avoid high cost, pertinence and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Weigh 200 kg of industrial brine with a salt content of 23%, 50 kg of starch, 20 kg of peptone, and 510 kg of water, adjust the pH value of the solution to 7.0-7.2, heat up to 40-55°C and stir evenly, then Sterilize by heating to 125°C for 25 minutes;

[0040] 2. After cooling down to 40-60°C, add 20 kg of yeast extract, 50 kg of Halobacterium species, 50 kg of extreme thermophilic archaea species, and 100 kg of wax-loving species into the fermenter, keeping the temperature at After fermenting at 55-60° C. for 40-48 hours, cool to normal temperature to obtain 1000 kg of microbial paraffin-removing agent for oil wells with high wax content, high temperature and high mineralization.

Embodiment 2

[0042] 1. Weigh 210 kg of industrial brine with a salt content of 23%, 60 kg of starch, 20 kg of peptone, and 460 kg of water, adjust the pH value of the solution to 7.0-7.2, heat up to 40-55°C and stir evenly, then Sterilize by heating to 125°C for 25 minutes;

[0043] 2. After cooling down to 40-60°C, add 20 kg of yeast extract, 60 kg of Halobacterium species, 60 kg of extreme thermophilic archaea species, and 110 kg of wax-loving species into the fermenter, keeping the temperature at After fermenting at 55-60° C. for 44-48 hours, cool to normal temperature to obtain 1000 kg of microbial paraffin-removing and anti-paraffin agent for oil wells with high wax content, high temperature and high mineralization.

Embodiment 3

[0045] 1. Weigh 210 kg of industrial brine with a salt content of 23%, 70 kg of starch, 20 kg of peptone, and 430 kg of water, adjust the pH value of the solution to 7.0-7.2, heat up to 40-55°C and stir evenly, then Sterilize by heating to 125°C for 25 minutes;

[0046] 2. After cooling down to 40-60°C, add 20 kg of yeast extract, 70 kg of Halobacterium species, 70 kg of extreme thermophilic archaea species, and 110 kg of wax-loving species into the fermenter, keeping the temperature at Ferment at 55-60° C. for 46-48 hours and then cool to normal temperature to obtain 1000 kg of microbial paraffin-removing agent for high-waxy, high-temperature, high-mineralized oil wells.

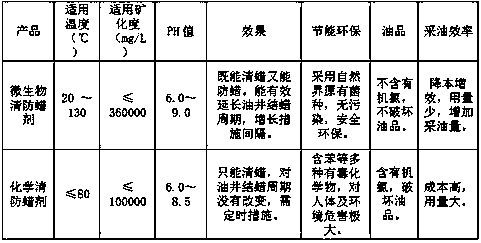

[0047] Table 1 and Table 2 below are performance indicators of the present invention and a comparison with other wax removal and anti-wax technology scopes of application:

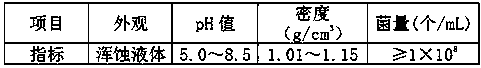

[0048] Table 1 Performance Index of Microbial Wax Removing and Preventing Agent of the present invention

[0049]

[0050] Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com