Copper infiltration technology, copper infiltration material prepared through copper infiltration technology, and application

A copper infiltration and process technology, applied in the field of metal composite material preparation, can solve the problems of low product qualification rate, high production cost, long copper infiltration cycle, etc., and achieve the effects of high product qualification rate, low cost and short process cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

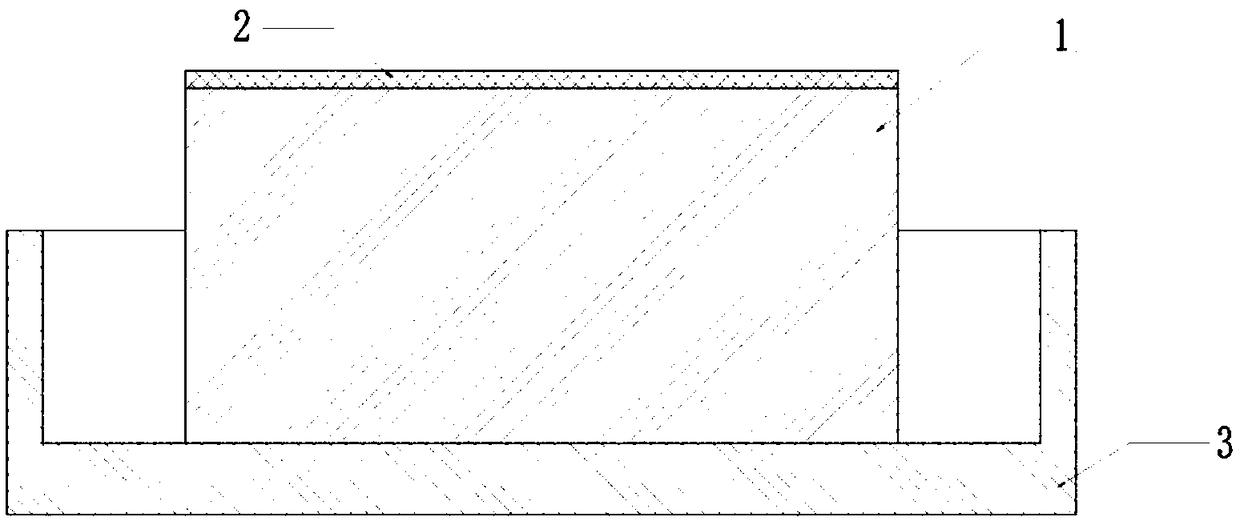

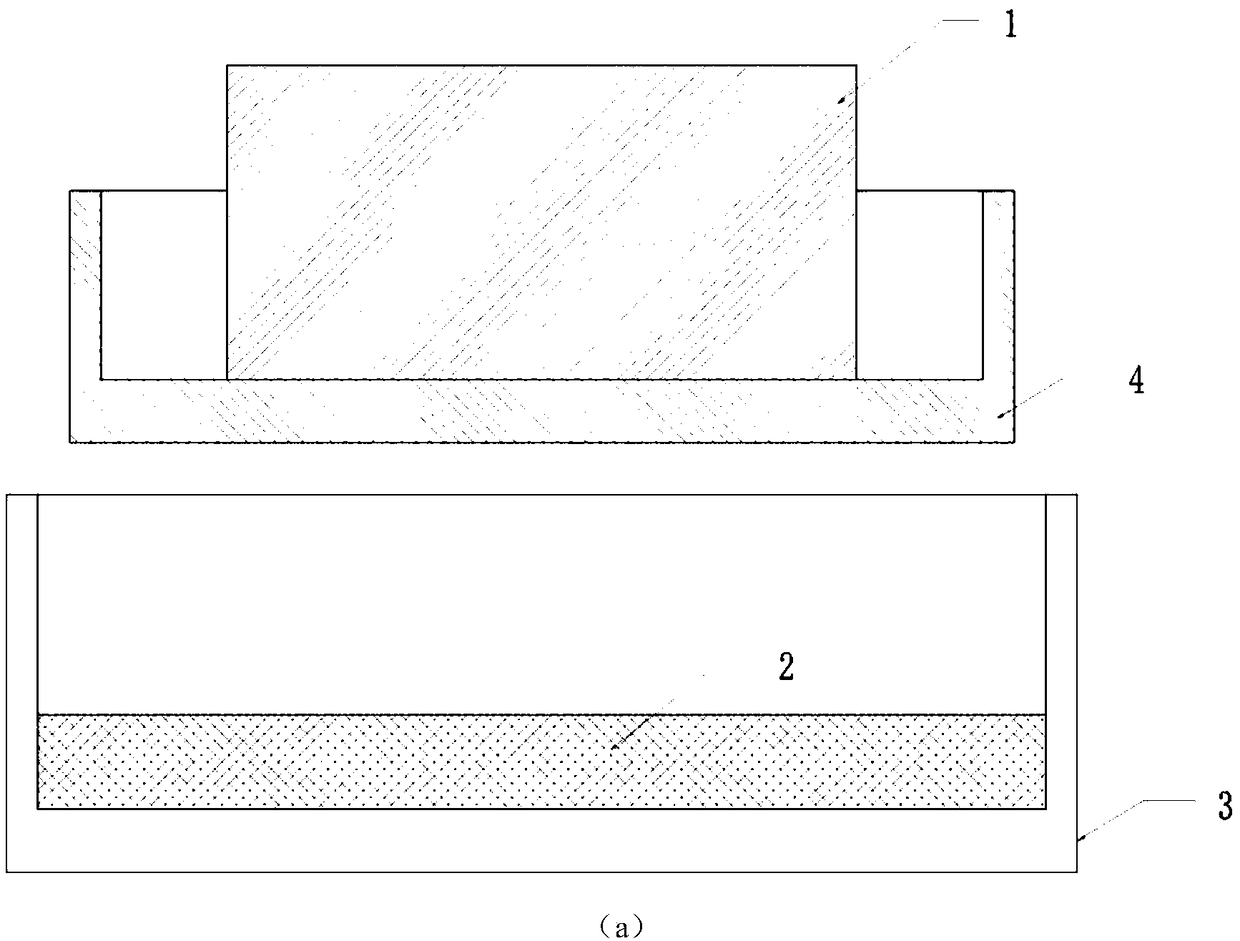

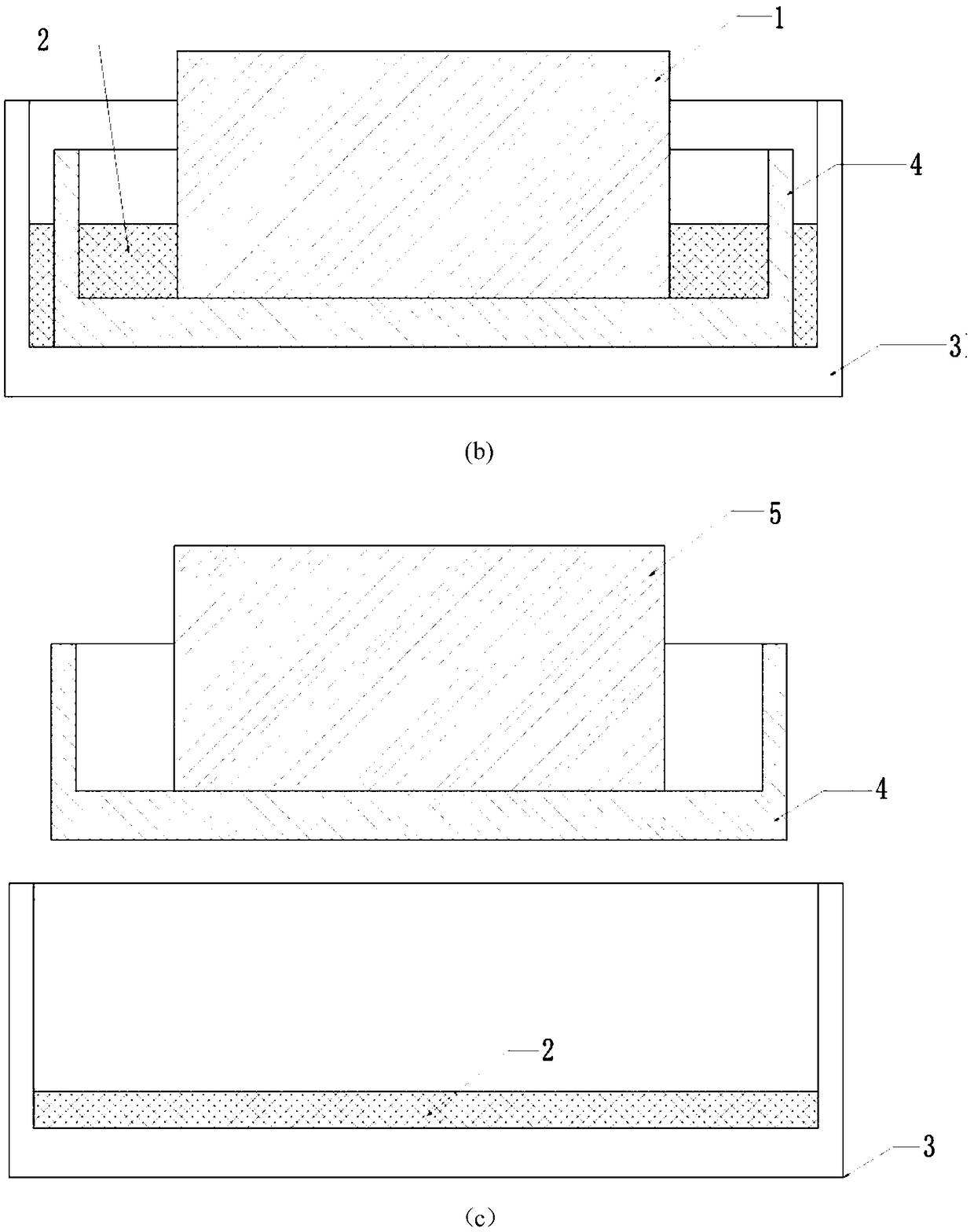

[0043] Such as image 3 As shown in the schematic diagram of the copper infiltration process, the tungsten copper infiltration material described in this embodiment is prepared by the following process, which specifically includes the following steps:

[0044] (1) Fill the metal tungsten powder in the mold for powder molding, press molding under the pressure condition of 200MPa, prepare the tungsten skeleton green body, demold the prepared skeleton green body, reshape it, install it in the furnace, and sinter it under the hydrogen atmosphere, Control the sintering temperature to 2400°C, keep it warm for 5 hours, and cool to obtain the required porous tungsten skeleton 1 sintered billet;

[0045] (2) The porous tungsten skeleton 1 prepared above is burnt into a selected graphite crucible 3 to ensure that there is a gap between them, and electrolytic copper is added to the crucible as an infiltration agent 2. In this embodiment , calculate the amount of electrolytic copper adde...

Embodiment 2

[0049] Such as image 3 As shown in the schematic diagram of the copper infiltration process, the tungsten copper infiltration material described in this embodiment is prepared by the following process, which specifically includes the following steps:

[0050] (1) Fill the metal tungsten powder in the mold for powder molding, press molding under the pressure condition of 200MPa, prepare the tungsten skeleton green body, demold the prepared skeleton green body, reshape it, install it in the furnace, and sinter it under the hydrogen atmosphere, Control the sintering temperature to 2200°C, keep it warm for 4 hours, and cool to obtain the required porous tungsten skeleton 1 sintered billet;

[0051] (2) The porous tungsten skeleton 1 prepared above is burnt into a selected graphite crucible 3 to ensure that there is a gap between them, and electrolytic copper is added to the crucible as an infiltration agent 2. In this embodiment , calculate the amount of electrolytic copper adde...

Embodiment 3

[0055] Such as image 3 As shown in the schematic diagram of the copper infiltration process, the molybdenum copper infiltration material described in this embodiment is prepared by the following process, which specifically includes the following steps:

[0056] (1) Fill metal molybdenum powder in a mold for powder molding, press molding under 150MPa pressure condition, prepare molybdenum skeleton green body, demould and shape the prepared molybdenum skeleton green body, put into furnace for sintering under hydrogen atmosphere , control the sintering temperature to 1700°C, carry out heat preservation and sintering for 5 hours, and cool to obtain the required porous molybdenum skeleton 1 sintered billet;

[0057] (2) The porous molybdenum skeleton 1 prepared above is burnt into the selected graphite boat crucible 3 to ensure that there is a gap between them, and electrolytic copper is added to the crucible as the infiltration agent 2. In this embodiment , calculate the amount ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com