Open caisson underwater efficient soil taking platform device used under complicated geological conditions

A technology of complex geological conditions and platform devices, which is applied in the field of high-efficiency soil extraction platform devices under caissons, can solve the problems of large influence of water depth, low overall efficiency, and unsatisfactory effect of breaking soil in the hydraulic mud suction method, so as to achieve improved crushing and soil borrowing efficiency, social and economic benefits are obvious, and the effect of expanding the soil borrowing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

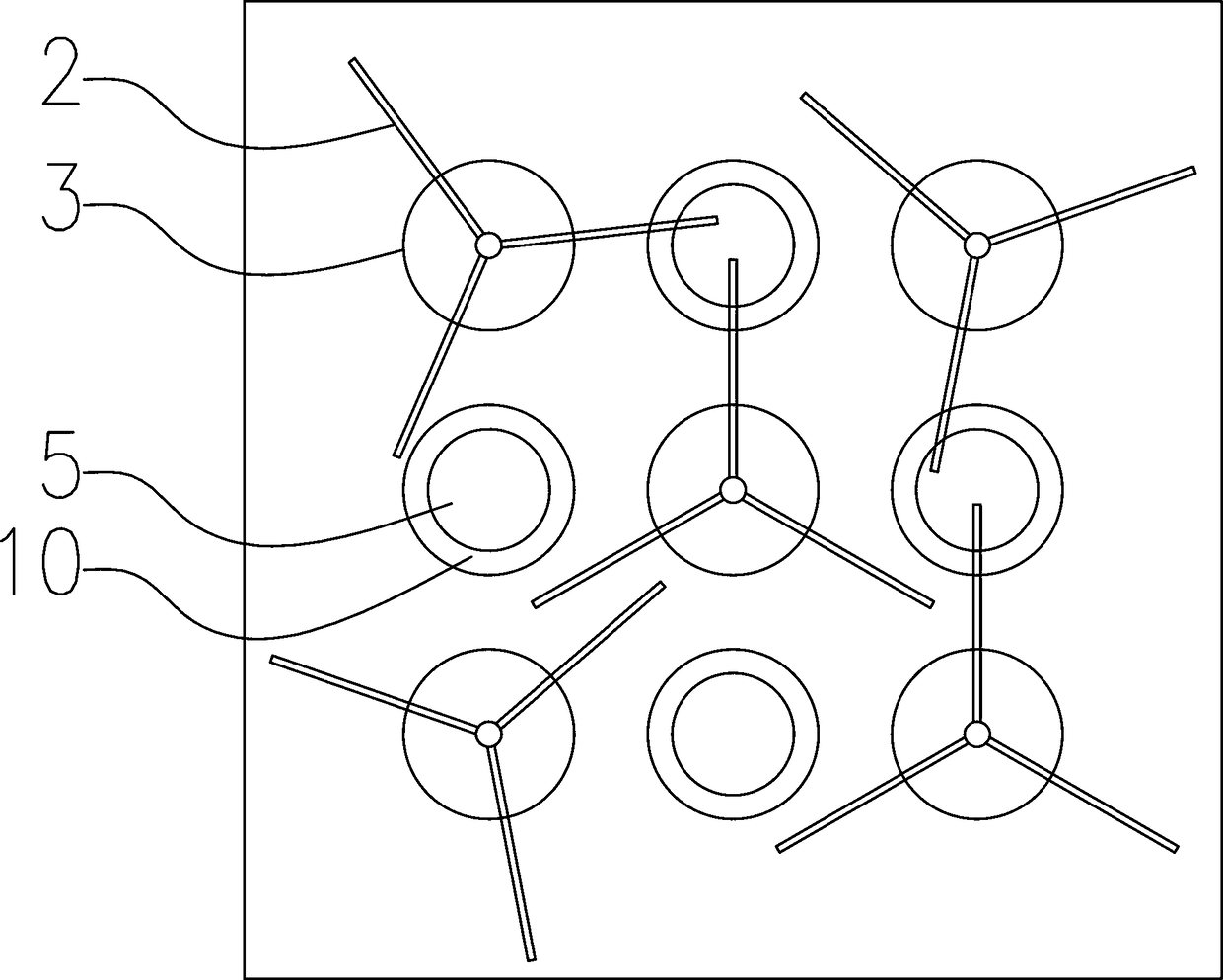

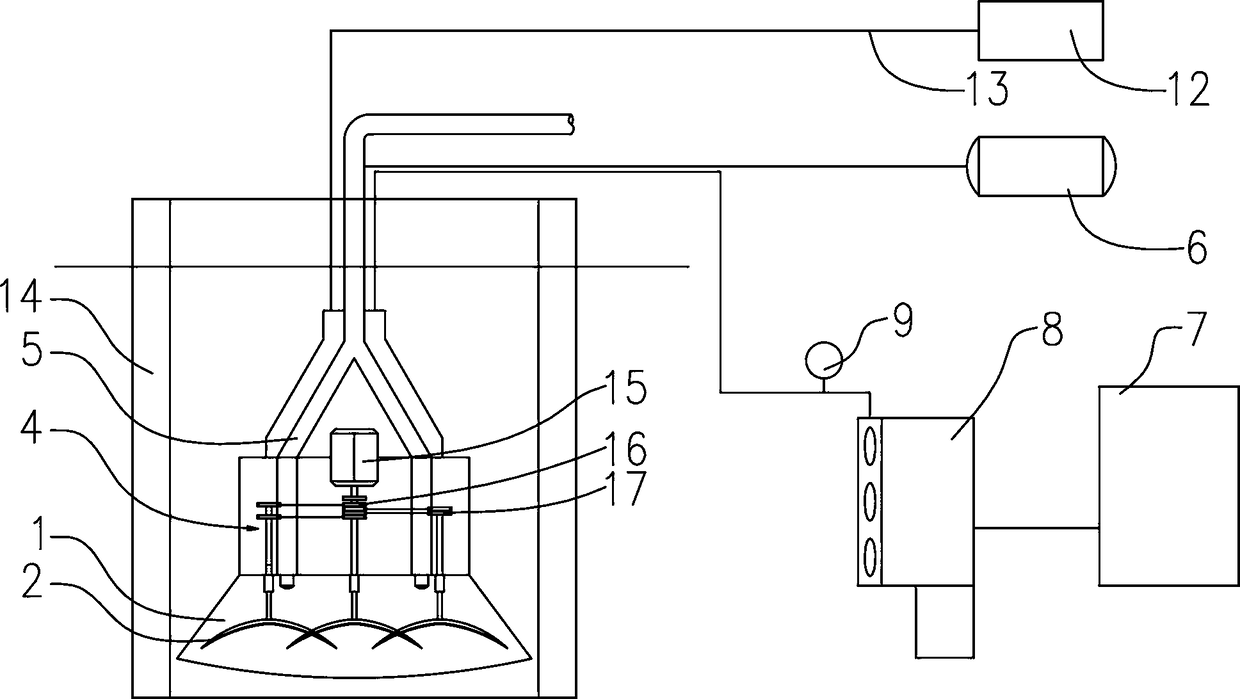

[0033] Such as Figure 1~2 Among them, an underwater high-efficiency earth-borrowing platform device for caissons under complex geological conditions, the waterproof and sealed platform 4 is interlaced with drilling rig devices 3 and suction pipes 5;

[0034] The drill bit 2 of the drilling rig device 3 stretches out of the bottom of the waterproof sealing platform;

[0035] The end of the suction pipe 5 stretches out of the bottom of the waterproof sealing platform 4;

[0036] The bottom of the waterproof sealing platform 4 is also provided with a rotary nozzle 11, which is connected with a high-pressure water pipe 10. The rotary nozzle 11 faces the gap between the drill bit 2 and the drilling rig 3, and can clean the drill bit 2 while breaking the soil layer. Such as figure 1 Among them, there are 9 openings on the waterproof sealing platform 4, among which there are 5 openings on the drilling rig device 3, and 4 openings on the suction pipe 5, which are arranged in a sta...

Embodiment 2

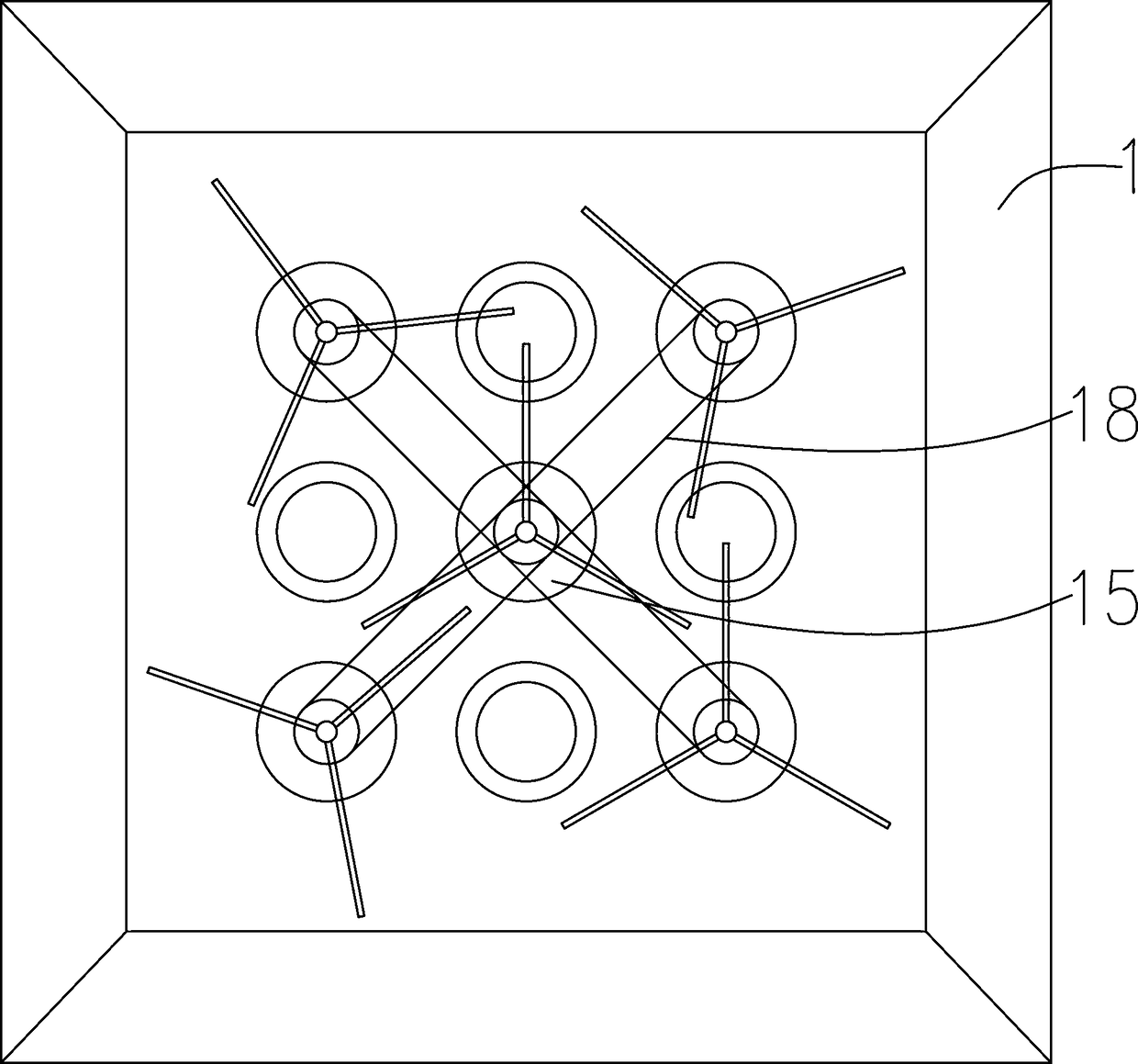

[0038] On the basis of Example 1, the preferred scheme is as Figure 2~5 In the above-mentioned drilling device 3, the variable frequency motor 15 is connected to the shaft 19 of the drilling device 3 in the middle, and the shaft 19 is provided with a plurality of main transmission wheels 16 in the axial direction, and the shafts of the surrounding drilling device 3 The rod 19 is provided with a slave transmission wheel 17, and the main transmission wheel 16 is connected with the slave transmission wheel 17 by a transmission chain 18;

[0039] The variable frequency motor 15 is sealed and installed in the waterproof sealing platform 4 , and the variable frequency motor 15 is electrically connected with the power supply device 12 through the waterproof wire 13 . With this structure, one variable frequency motor 15 can drive the shafts of five drilling rig devices 3 to rotate synchronously. The advantage of adopting the synchronous rotation scheme is that in the preferred scheme...

Embodiment 3

[0048] On the basis of Examples 1 and 2, the preferred scheme is as figure 2 Among them, the suction pipe 5 is connected with the air compressor 6 through a pipeline. The suction of the mud suction pipe 5 is realized by the pressure of the air compressor 6 .

[0049] In a preferred solution, the high-pressure water pipe 10 is connected to the output port of the supercharging device 8 , the input port of the supercharging device 8 is connected to the water supply tank 7 , and the high-pressure water pipe 10 is provided with a pressure sensor 9 . Preferably, the supercharging device 8 adopts a crankshaft multi-cylinder plunger pump to output high-pressure water flow. The inlet of the pressurizing device 8 is connected with the water supply tank 7 .

[0050] The preferred solution is as Figure 1~3 Among them, the high-pressure water pipe 10 is located at the periphery of the suction pipe 5, and the high-pressure water pipe 10 is sealed and connected with the waterproof seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com